Birotor rotary piezoelectric motor

A rotary pressure, electric motor technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. The realization of dual-rotor drive, affecting the application range of rotary piezoelectric motors, etc., achieves the effects of good speed and position control performance, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

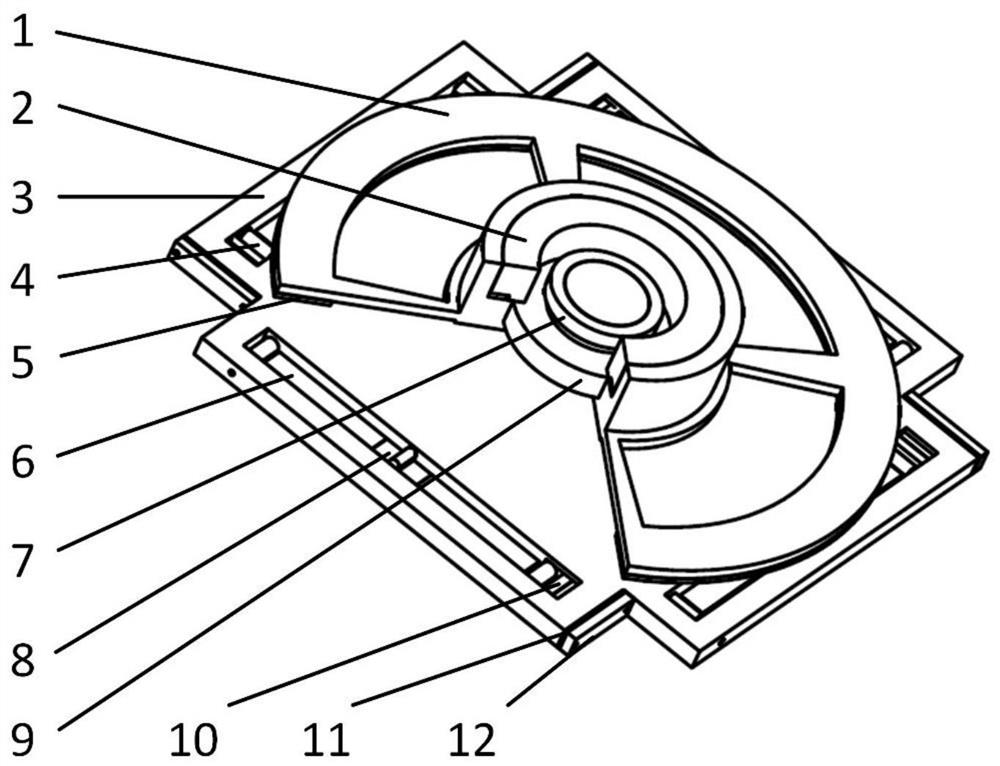

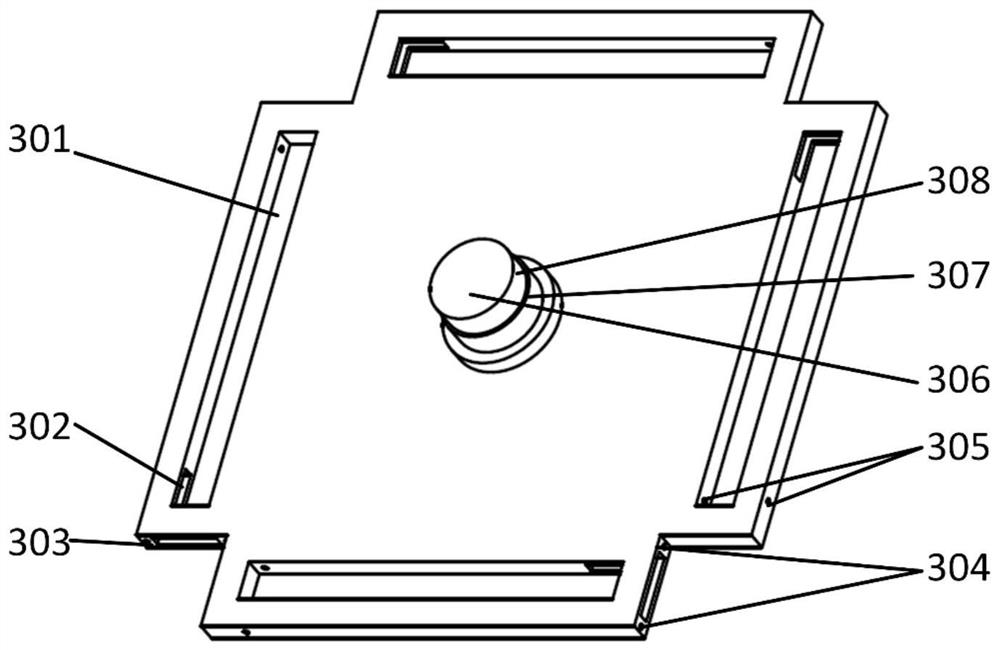

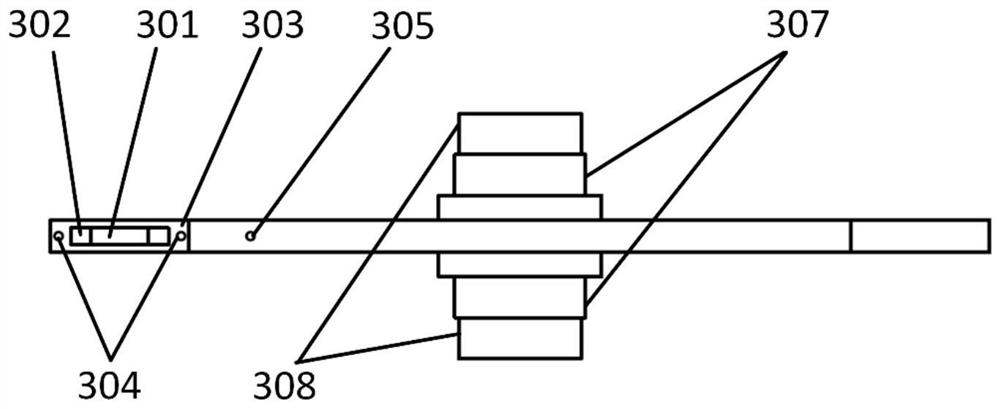

[0019] Such as figure 1 As shown, a dual-rotor rotary piezoelectric motor, the piezoelectric motor is a dual-rotor rotary piezoelectric motor driven by a flexible beam, specifically including: a base part, a stator part and a rotating part; as figure 2 and image 3 As shown, the base part includes a base 3, the base 3 is a square structure, including four stator installation slots 301, four slideways 302, four elastic plug installation surfaces 303, eight threaded holes 304, Eight mounting holes 305 for the rotating shaft at the hinged end, two bosses 306, two internal pressure screw mounting surfaces 307, two bearing inner ring mounting surfaces 308, and four stator mounting grooves 301 are square groove structures and are evenly distributed on the base On the seat 3, four slideways 302 are evenly distributed on the base and located inside the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com