Device for processing a workpiece

A technology for processing workpieces and plunger pumps, which is applied in the field of devices for processing workpieces, can solve problems such as optimal operation of unfavorable devices, and achieve the effects of improving processing results, optimizing cost-effectiveness, and optimizing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

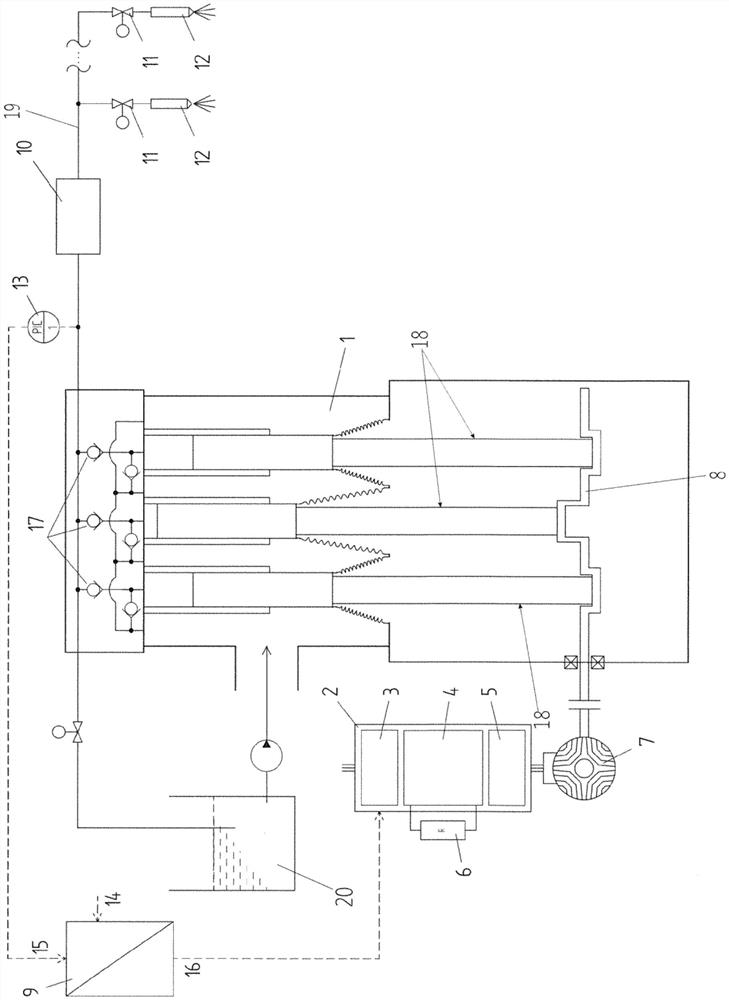

[0028] In the figures there is shown a device for machining workpieces, which has a plunger pump 1 comprising, in the example, three plungers 18 mounted on a crankshaft 8, preferably with respect to each other Offset by 120° and drivable in an oscillating manner by means of an electric motor connected to the crankshaft 8 .

[0029] The electric motor is designed as a reluctance motor 7 according to the invention and is connected to a frequency converter 2 comprising a rectifier 3 , a DC intermediate circuit 4 and an inverter 5 .

[0030] The braking resistor 6 is connected to the DC intermediate circuit 4 of the frequency converter 2, and when the reluctance motor 7 stops, the braking resistor realizes a rapid reduction of the speed of the crankshaft 8.

[0031] On the suction side, the plunger 18 is connected to a fluid accumulator 20 , while the fluid at high pressure after a working cycle of the plunger 18 is supplied in this example via a pressure line 19 into two consumer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com