Low-pressure fixation machine adopting second-order method for measuring humidity and water content measuring method

A technology of a greening machine and a second-order method, which is applied in the direction of water content of materials and tea treatment before extraction, which can solve the problems of difficult detection of water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

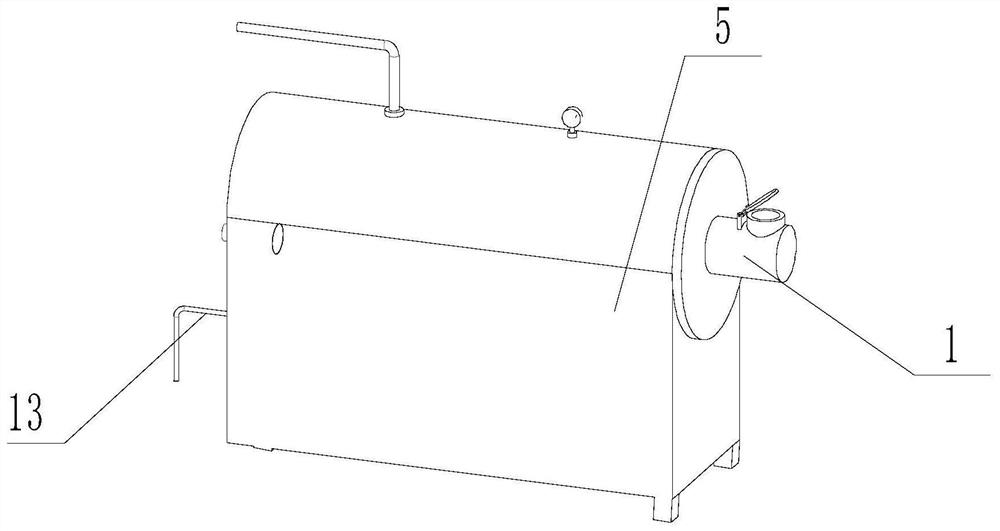

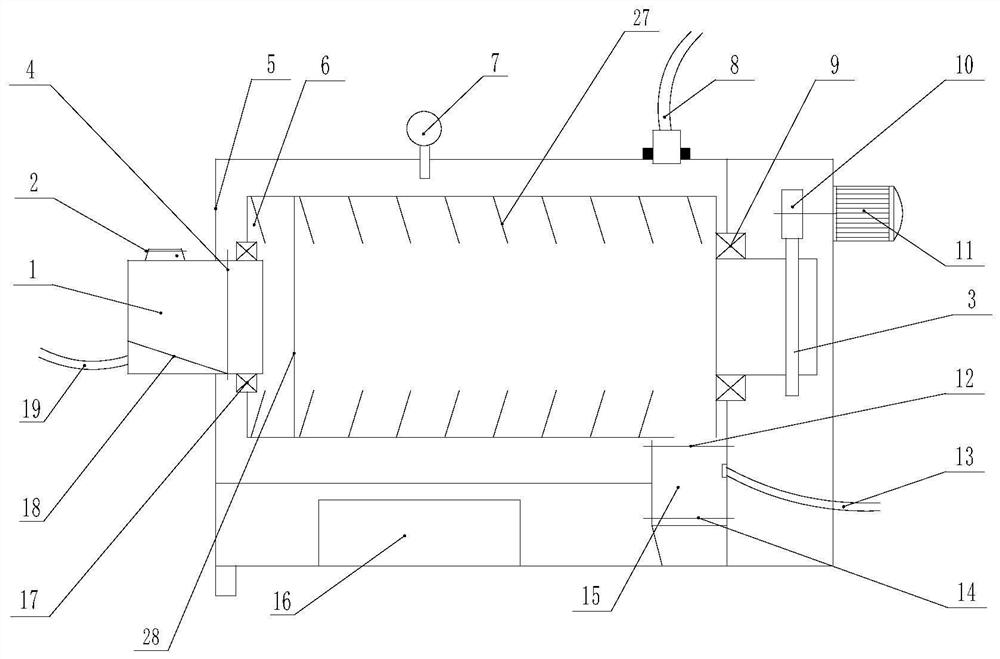

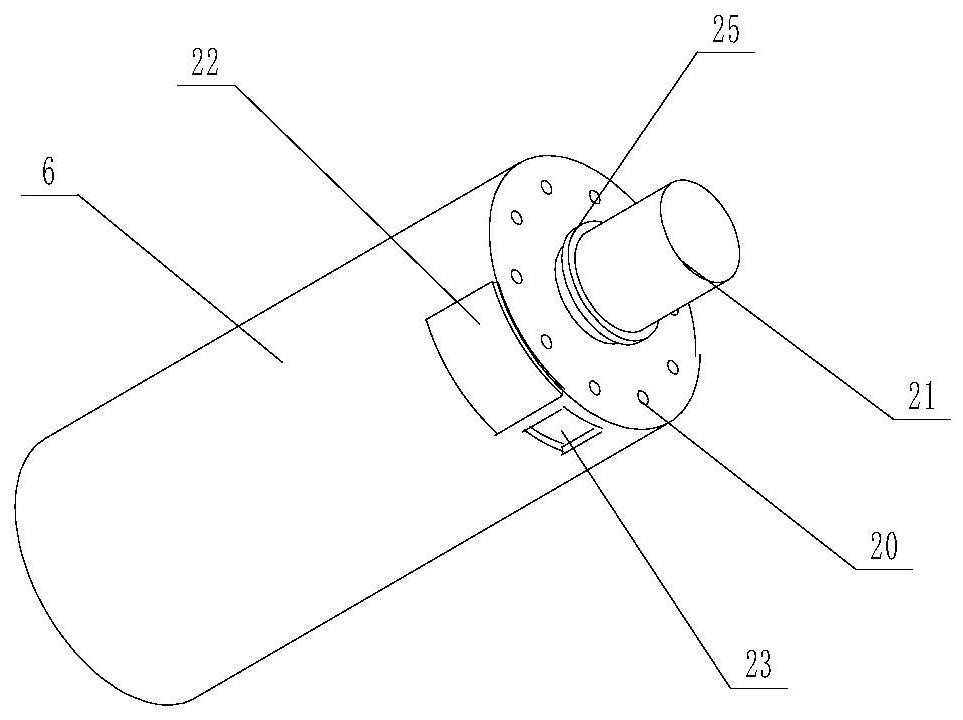

[0058] The present invention will be further described below in conjunction with accompanying drawing:

[0059] like Figure 1-8 As shown, a low-pressure greening machine for measuring humidity by a second-order method includes a low-pressure greening machine, a thermometer 7, a first air pump and a low-pressure air pipe 8, and the thermometer 7 is connected to the low-pressure greening machine and detects the temperature inside the low-pressure greening machine , one end of the low-pressure exhaust pipe 8 is connected inside the low-pressure deactivation machine, the other end of the low-pressure exhaust pipe 8 is connected to the gas inlet of the condenser 30 through the shut-off valve 29, and the hygrometer is arranged at the outlet of the other end of the low-pressure exhaust pipe 8.

[0060] The low-pressure cleaning machine includes an airtight casing 5, a low-pressure dehumidification tank 6, a feed bin 1, a microwave heating device 16, a feed bin 15, a baffle plate 28,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap