A thermally conductive sheet with high orientation arrangement of artificial graphite sheet and preparation method thereof

A technology of artificial graphite sheet and thermal conductive sheet, applied in chemical instruments and methods, heat exchange materials, coatings, etc., to achieve the effect of small pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

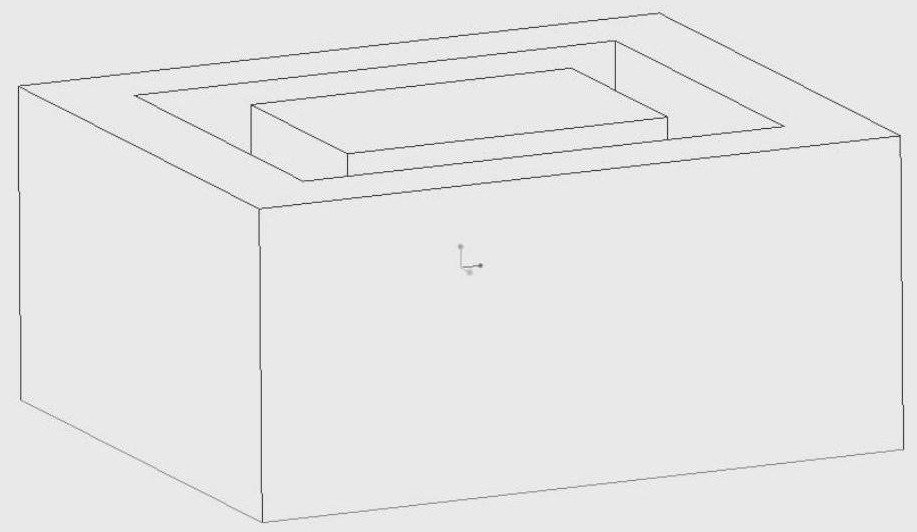

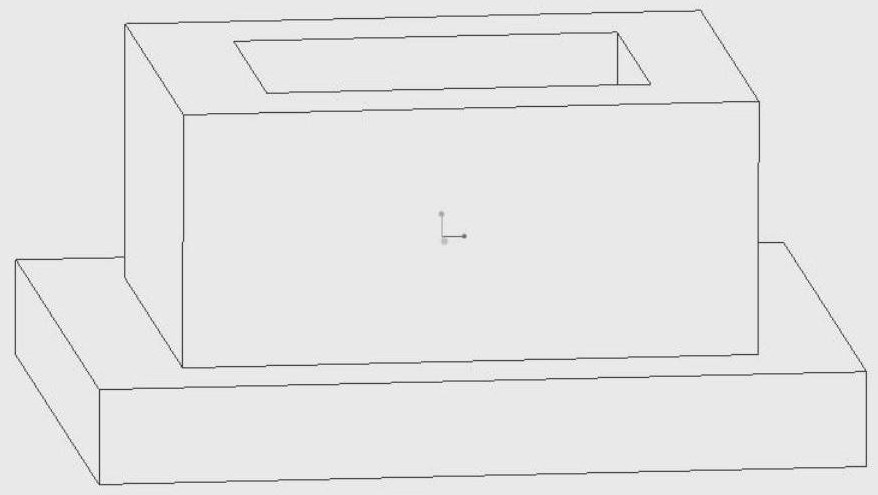

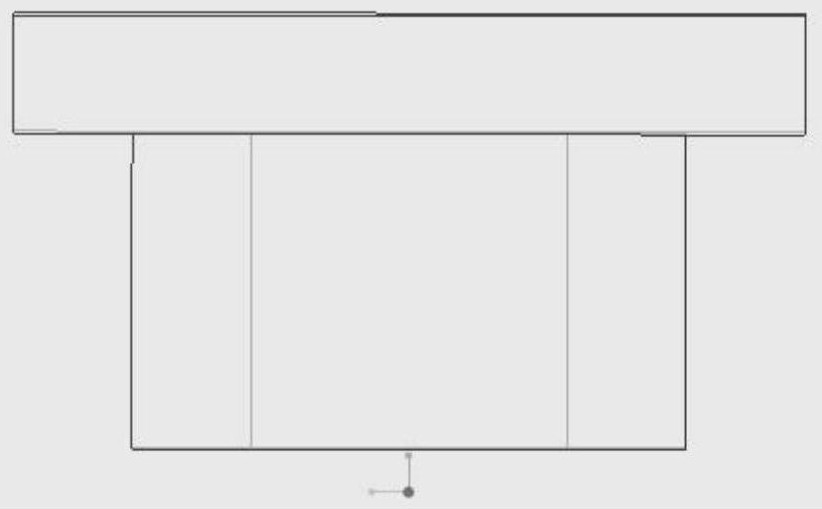

Image

Examples

Embodiment 1

[0056] Add 100g of vinyl silicone oil with a viscosity of 500mpa.s, 300g of 1-3um spherical alumina, 3g of graphene powder, 1g of alkylsilane coupling agent, and 1g of epoxy tackifier into the mixer and stir for 60min. Preparation of graphene composite high thermal conductivity mixture.

[0057] Place a 50um artificial graphite sheet in the mold, the thickness of the graphene composite high thermal conductivity mixture between the artificial graphite sheet layers is 0.08mm, and then lay a layer of artificial graphite sheet, and close the mold to solidify;

[0058] On the surface of the uppermost artificial graphite sheet, coat a layer of graphene composite high thermal conductivity mixture with a thickness of 0.08mm, then spread a layer of artificial graphite sheet, close the mold and solidify, repeat this step until the thickness of the block reaches the requirement;

[0059] The above mold clamping and curing include: pressure fastening, temperature rise, and heat preservati...

Embodiment 2

[0062] 100g of vinyl silicone oil with a viscosity of 500mpa.s, 100g of 1-3um spherical alumina, 70g of 0.5um spherical alumina, 150g of 1um aluminum nitride, 3g of graphene powder, 1g of alkyl silane coupling agent, 1g The epoxy tackifier was added into the mixer and stirred and mixed for 60 minutes to prepare the graphene composite heat-conducting mixture.

[0063] Place the 50um artificial graphite sheet in the mold, the graphene composite high thermal conductivity mixture between the artificial graphite sheet layers is 0.08mm, and then lay a layer of artificial graphite sheet, close the mold and solidify;

[0064] On the surface of the uppermost artificial graphite sheet, coat a layer of graphene composite high thermal conductivity mixture with a thickness of 0.08mm, then spread a layer of artificial graphite sheet, close the mold and solidify, repeat this step until the thickness of the block reaches the requirement;

[0065] The above mold clamping and curing include: pr...

Embodiment 3

[0068] 100g of vinyl silicone oil with a viscosity of 500mpa.s, 100g of 1-3um spherical alumina, 70g of 0.5um spherical alumina, 150g of 1um aluminum nitride, 3g of graphene powder, 1g of alkyl silane coupling agent, 1g The epoxy tackifier was added into the mixer and stirred and mixed for 60 minutes to prepare a graphene composite high thermal conductivity mixture.

[0069] Place the 50um artificial graphite sheet in the mold, the graphene composite high thermal conductivity mixture between the artificial graphite sheet layers is 0.08mm, and then lay a layer of artificial graphite sheet, close the mold and solidify;

[0070] On the surface of the uppermost artificial graphite sheet, coat a layer of graphene composite high thermal conductivity mixture with a thickness of 0.05mm, then lay a layer of artificial graphite sheet, close the mold and solidify, repeat this step until the thickness of the block reaches the requirement;

[0071] The above mold clamping and curing includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com