Method for preparing extra-high-strength beer by using extra-high-strength wort

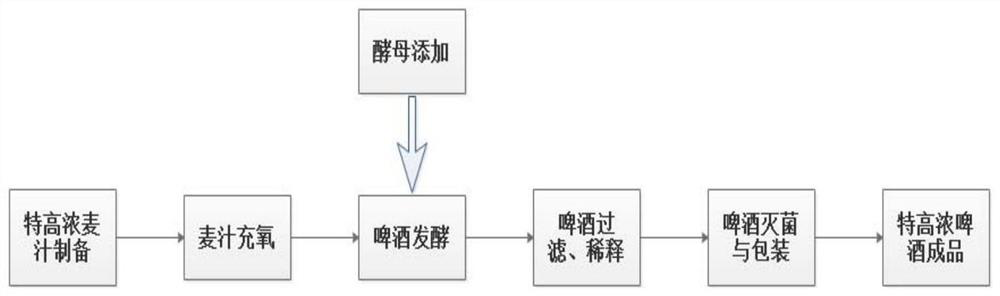

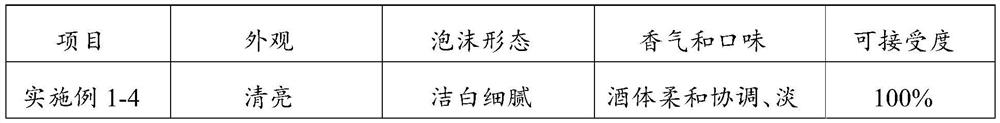

A high-concentration malt and wort technology, applied in the field of beer brewing, can solve the problems of reducing the production cost of ultra-high-concentration wort, difficult wort filtration, and prolonged filtration time, so as to improve the utilization rate of raw materials and improve the drinkability of products , highly acceptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

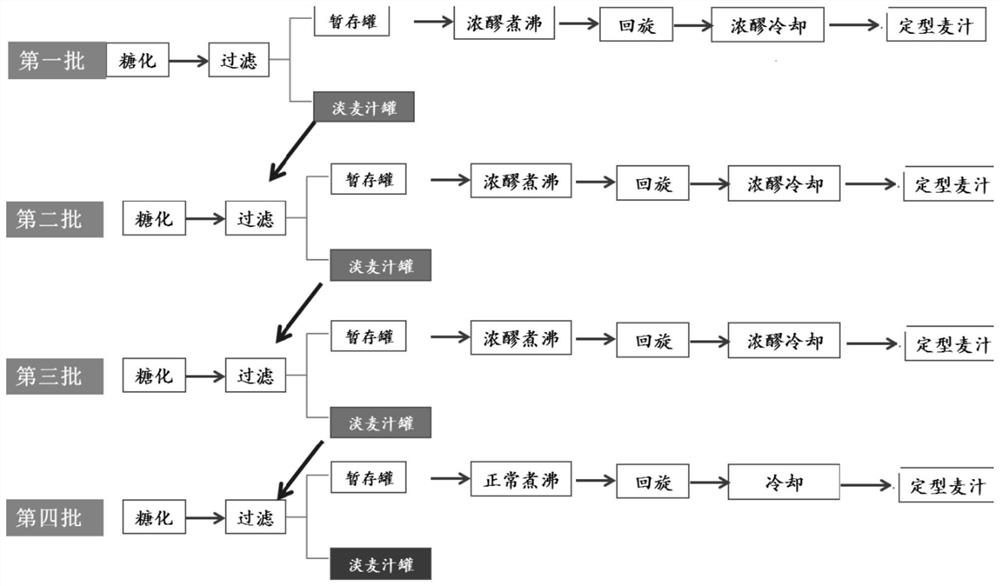

[0039] (S1) preparation of extra high-concentration wort:

[0040] S1-1: In the saccharification pot, the pulverized malt is rested, then heated to 63-68°C, saccharified for 60-80min, and after passing the iodine test, the temperature is raised to 76-78°C and then transferred to a filter tank for filtration;

[0041] S1-2: When the filtered wort leaks the bad layer, the first wort is filtered, and the first wort enters the wort temporary storage tank;

[0042] S1-3: After the first wort is filtered, add hot water at 76-78°C into the filter tank, wash the wort remaining in the wort, and call it the second wort;

[0043] S1-4: Mix 70-100% of the second wort with the first wort and put it into a boiling pot, and boil it with thick mash, add hops or hop products during the boiling process, 5-10min before the end of boiling After mixing with syrup, all of them are poured into the rotary sedimentation tank;

[0044] S1-5: After the high-concentration wort that boils finishes, pass...

Embodiment 1

[0082] The present embodiment provides a kind of preparation method of extra high-strength beer, and its method is as follows:

[0083] S1: Preparation of extra high-strength wort

[0084] S1-1: In the mashing pot, the pulverized malt was rested at 45°C for 40min, then the temperature was raised to 63°C, saccharified for 60min, and after passing the iodine test, the temperature was raised to 76°C and then transferred to the filter tank for filtration;

[0085] S1-2: When the filtered wort exposes the bad layer, the filtration of the first wort is completed, and the first wort enters the wort temporary storage tank;

[0086] S1-3: After the first wort filtration is completed, add hot water at 76°C into the filter tank to wash the wort remaining in the wort, which is called the second wort filtration, the second wort The filtered residual sugar concentration is 0.8°P;

[0087] S1-4: Mix 92% of the second wort with the first wort and put it into a boiling pot to boil with thick...

Embodiment 2

[0093] The present embodiment provides a kind of preparation method of extra high-strength beer, and its method is as follows:

[0094] Q1: Preparation of extra high-strength wort

[0095] Q1-1: In the mashing pot, the pulverized malt was rested at 50°C for 40min, then heated to 65°C, saccharified for 65min, after passing the iodine test, heated to 78°C and transferred to the filter tank for filtration;

[0096] Q1-2: When the filtered wort exposes the bad layer, the first wort filtration is completed, and the first wort enters the wort temporary storage tank;

[0097] Q1-3: After the first wort filtration is completed, add hot water at 76°C to the filtrate, wash the wort remaining in the wort, and call it the second wort filtration, the second wort The filtered residual sugar concentration is 1.5°P;

[0098] Q1-4: After mixing 84% of the second wort with the first wort, put it into the boiling pot, and boil it with thick mash. During the boiling process, add 0.15% hop extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com