Method and system for reducing energy consumption, electrolyzing water to produce hydrogen and symbiotically value-adding chemicals

A technology for electrolysis of water and chemicals, applied in the field of electrochemical catalysis, can solve the problems of increasing the difficulty of purifying reaction products, restricting development and large-scale application, and affecting the utilization rate of chemicals, so as to improve the efficiency of hydrogen evolution with low energy consumption and achieve high efficiency value-added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

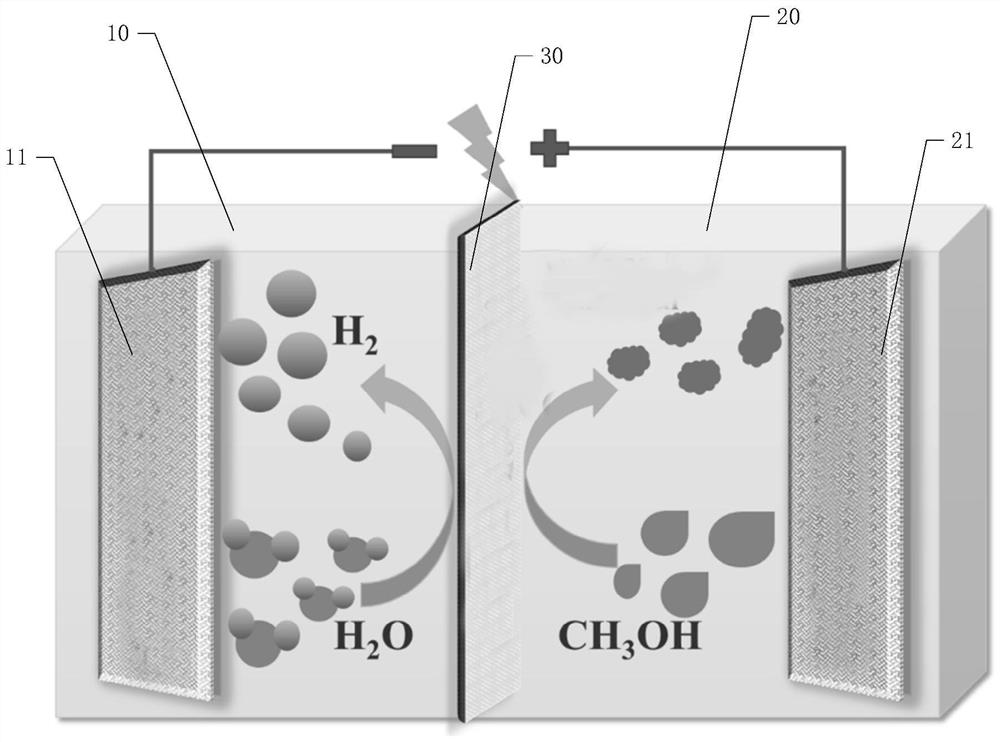

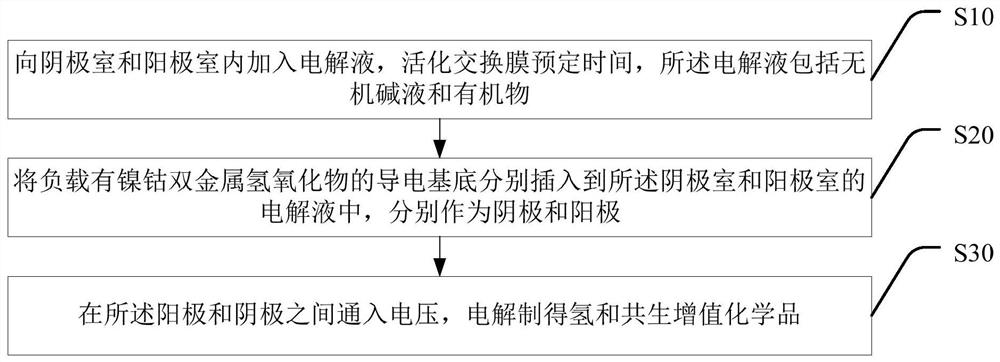

[0047] The commonly used non-precious metal nickel-cobalt double metal hydroxide is used as a catalyst, loaded on commercial nickel foam to form an electrode, and it is subjected to methanol oxidation reaction (referred to as MOR), oxygen evolution reaction (referred to as OER) and hydrogen evolution reaction (referred to as for HER) and other electrochemical tests.

Embodiment 2

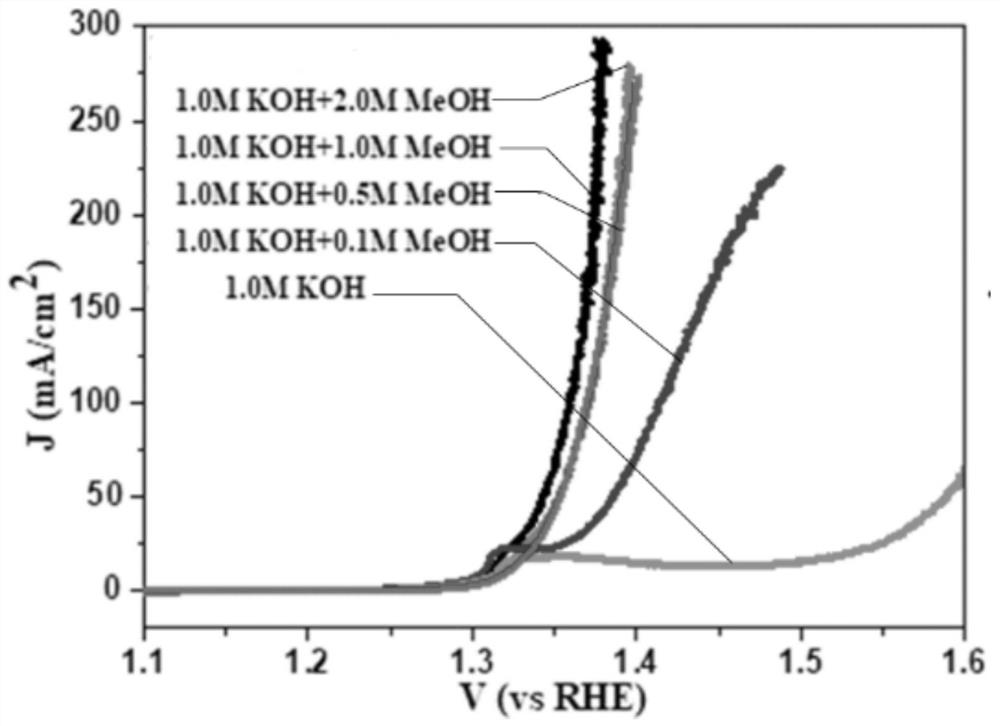

[0049] At room temperature, the oxygen evolution performance was tested on a CHI 760E electrochemical workstation using a traditional three-electrode system, and the Hg / HgO electrode and the Pt sheet were used as the reference electrode and the counter electrode, respectively. The foamed nickel electrode material loaded with nickel-cobalt double metal hydroxide in Example 1 is used for cyclic voltammetry curve test, and the electrolyte is respectively

[0050] 1) 1.0M potassium hydroxide, test OER performance;

[0051] 2) 1.0M potassium hydroxide and different concentrations of methanol to test the MOR performance,

[0052] Compare the test curve as image 3 As shown, the electrode material exhibited good OER and MOR catalytic performance. And in 1.0M potassium hydroxide, obvious oxidation reaction occurred on the surface of the electrode material. After adding 0.5M methanol into the electrolyte, it can be seen from the comparison that the oxidation reaction potential of me...

Embodiment 3

[0054] The nickel foam electrode material loaded with nickel-cobalt double metal hydroxide in Example 1 and the traditional three-electrode system were used to test the hydrogen evolution performance on a CHI 760E electrochemical workstation, and the electrolyte was 1.0M potassium hydroxide and 0.5M methanol. Depend on Figure 4 It can be found from the linear polarization curve that the material still has excellent hydrogen evolution performance after methanol is added to the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com