Antibacterial, inner-warm and anti-wrinkle compound functional fine and coarse combination product and processing method thereof

A technology with composite functions and processing methods, which is applied in the direction of textiles and papermaking, textile, fiber chemical characteristics, etc., can solve problems such as unsatisfactory use effect and unsatisfactory use process, achieve single performance change, novel thinking, and broad market The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

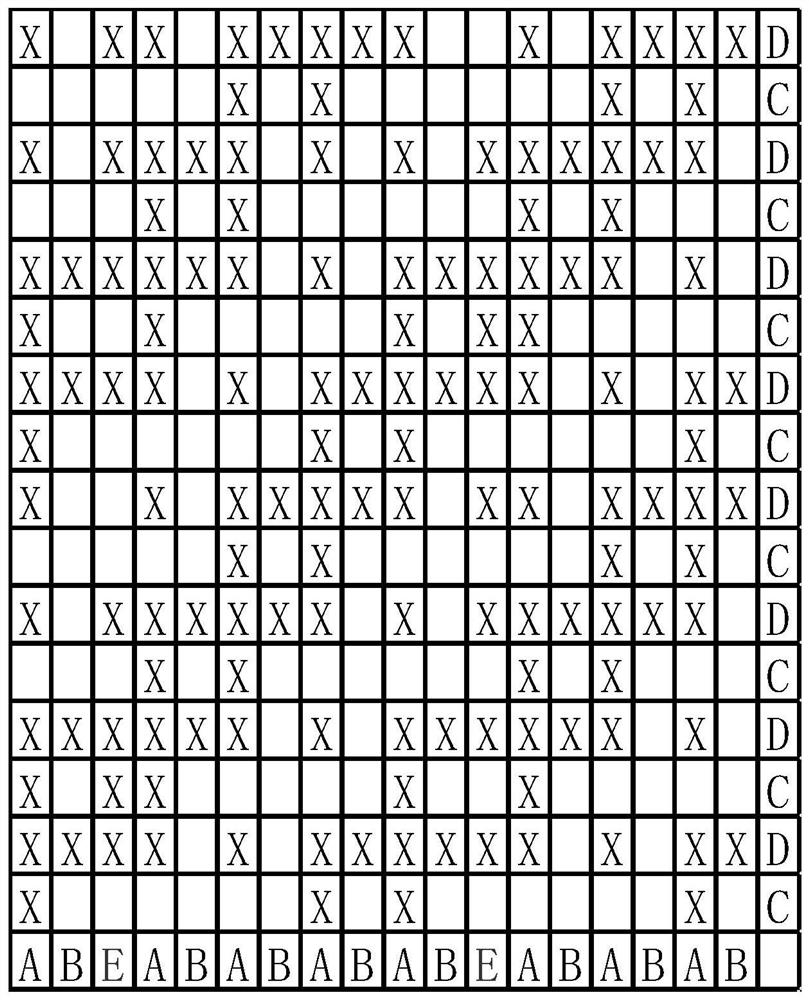

[0039] A kind of antibacterial, internal warming, anti-wrinkle compound functional fine-coarse combination product and processing method The processing method includes three steps, the first step is the selection of raw materials and the determination of the blending ratio, the second step is the selection and determination of the yarn twist coefficient, and the third step is Step fabric structure design and specification design.

Embodiment 2

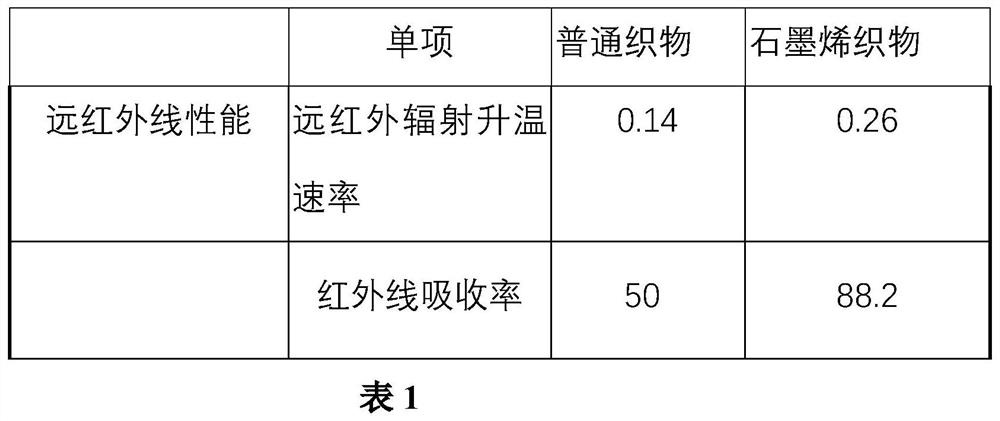

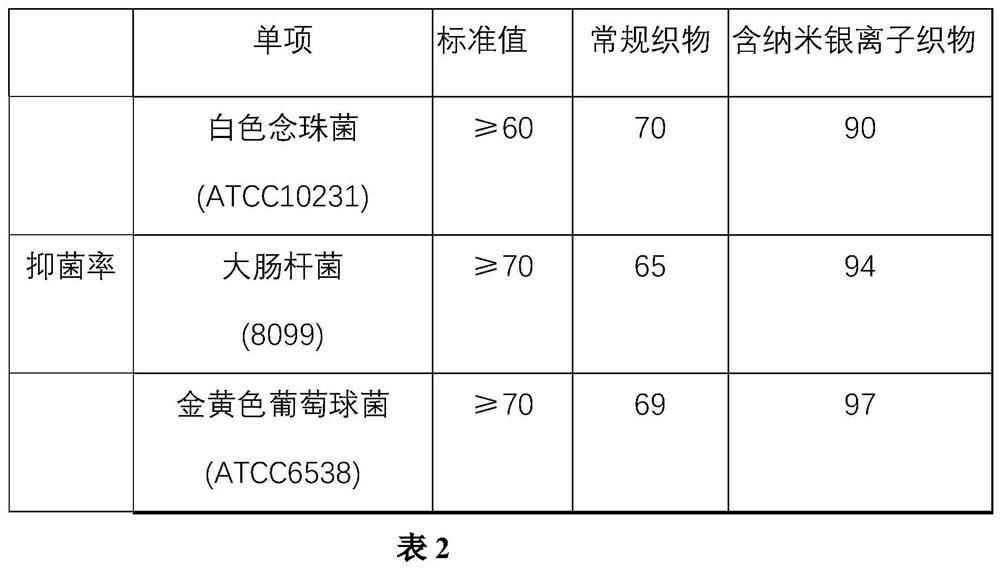

[0041] A kind of antibacterial, internal warming, anti-wrinkle compound function fine and coarse combination product and processing method described in embodiment 1, the selection of the first step raw material and the determination of the blending ratio are wool and biomass graphene fiber blending, with The increase of the proportion of biomass graphene content increases the far-infrared heating rate value of the fabric; the content of biomass graphene fiber is too low, the fabric has a low absorption rate of far-red light, and the warmth retention effect is poor; the content of biomass graphene fiber is too high, the fabric The hand feel is hard, and the anti-pilling effect is poor; comprehensively consider the spinnability of wool, the characteristics of different raw materials, the hand style of the fabric and other factors; surface layer: 19.5um Australian wool 40%, 2.5D biomass graphene (nylon matrix) fiber 60 %, the yarn is spun by blending Australian wool tops and wool-...

Embodiment 3

[0050] A kind of antibacterial, internal warming, anti-wrinkle composite functional fine-thick combination product and processing method described in Example 1, the selection and determination of the yarn twist coefficient in the second step are determined by the yarn twist and the wrinkle resistance of the fabric, the fabric's It is related to the pilling performance; the twist affects the interaction state between the fibers in the yarn. When the twist is too small, the force between the fibers in the yarn is weak, and when the external force is applied, the fibers tend to slip and form new positions. Wrinkles are not easy to recover; when the twist is too large, the fibers in the yarn will form a large deformation due to twisting. When subjected to external force, the elastic deformation can be reduced and the plastic deformation can be increased, which will reduce the wrinkle resistance of the product; reasonable yarn The influence of thread twist on the wrinkle resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com