Automatic rod adding device and rod adding method for coal mine underground tunnel drilling rig

A technology for tunnel drilling rigs and rod devices, which is applied to drill pipes, drill pipes, and earthwork drilling and mining, and can solve problems such as high safety risks, low efficiency, and high labor intensity, and achieve high operating accuracy, lower processing accuracy requirements, and low center of gravity good location effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

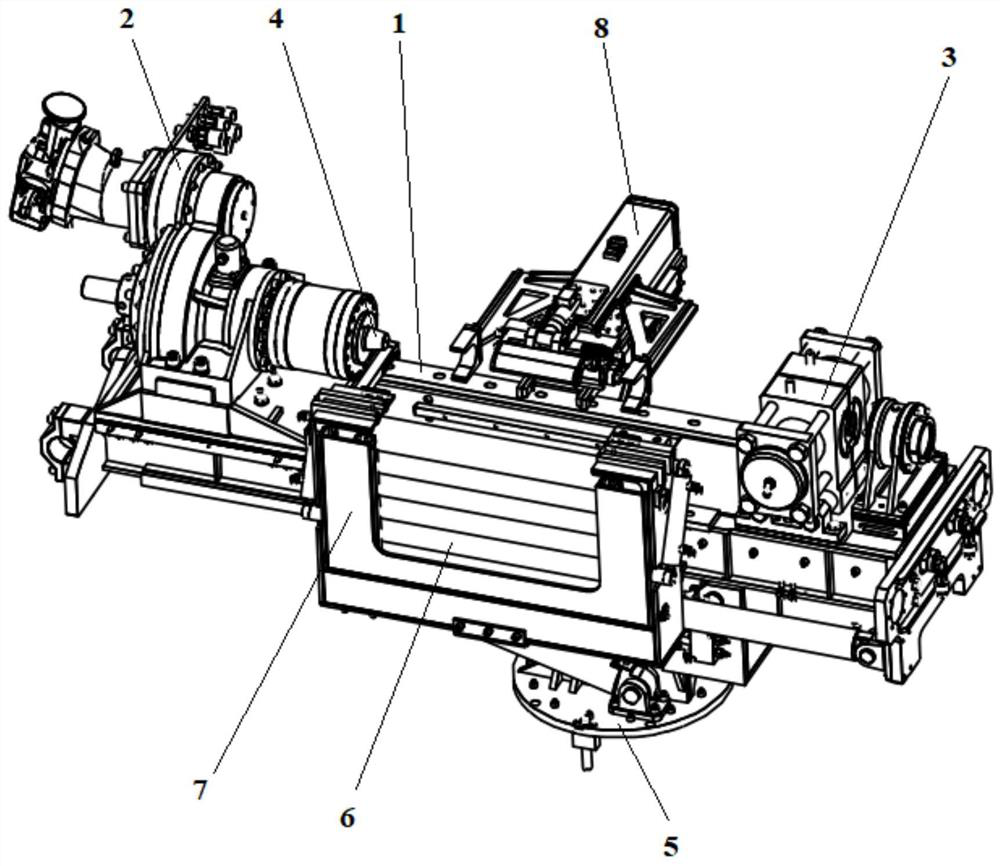

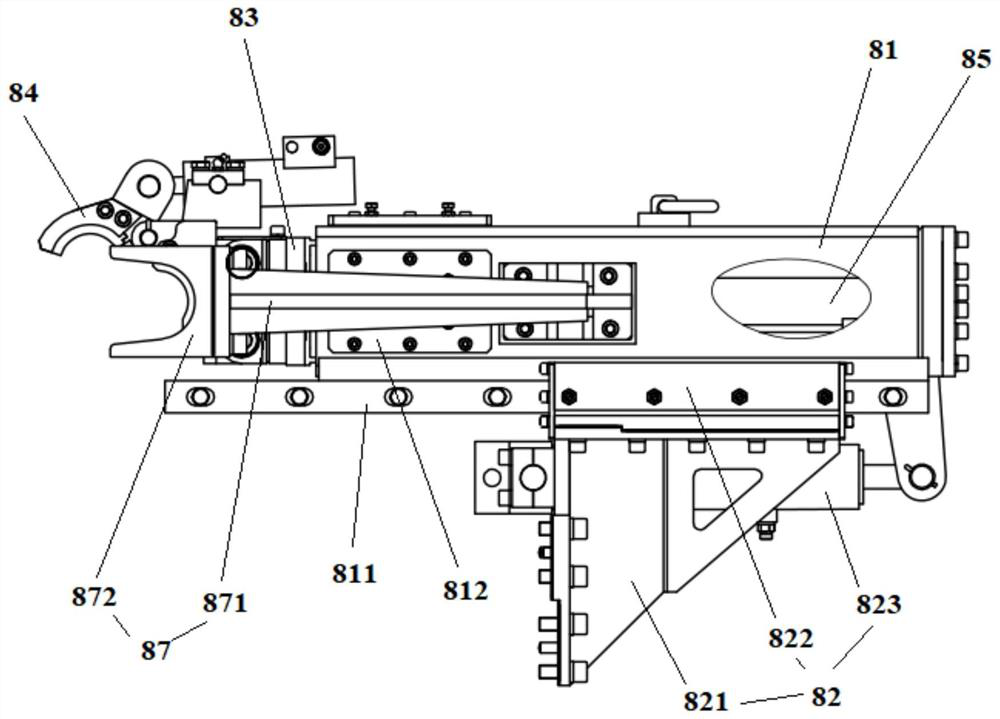

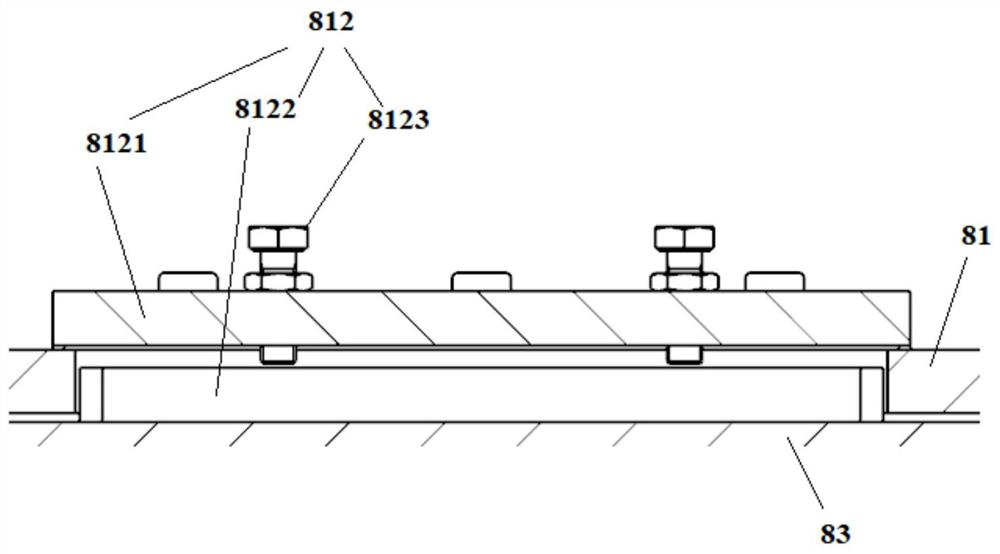

[0066] Such as Figure 1 to Figure 8 As shown, the present embodiment provides an automatic rod-adding device for an underground tunnel drilling machine in a coal mine, including a feeding device 1, a power head 2 and a holder 3, and the power head 2 can move along the linear slide rail of the feeding device 1 and The power head 2 clamps the active drill pipe 4, and the active drill pipe 4 is coaxially opposite to the holder 3; the power head 2 provides the rotary torque for the drilling machine; The feeding device 1 reciprocates in the direction of the linear slide rail, that is, provides the feeding and pulling force for the drilling tool; the active drill rod is clamped by the power head 2 to transmit the torque and propulsion to the drilling tool in the hole; the angle adjustment device 5 can Adjust the azimuth and the inclination of the main shaft; the clamper 3 is used to clamp the drilling tool in the hole, and cooperate with the power head 2 to realize the unscrewing a...

Embodiment 2

[0093] This embodiment provides a method for adding rods of an automatic rod adding device for an underground tunnel drilling rig in a coal mine, including the following steps:

[0094] Step 1, return the power head of the drilling rig to the rear end of the feeding device;

[0095] Step 2, keep the drill pipe magazine push-out cylinder fully retracted;

[0096] Step 3, operate the lifting mechanism to lift the drill pipe to be added to the top of the drill pipe warehouse;

[0097] Step 4, fully retract the second telescopic oil cylinder and fully extend the first telescopic oil cylinder, send the claw mechanism to the drill pipe warehouse, and coincide with the axis of the drill pipe to be added;

[0098] Step 5, extend the gripper cylinder to tighten the front and rear claws to tighten the drill pipe;

[0099] Step 6, fully retract the first telescopic oil cylinder so that the claw mechanism moves to coincide with the axis of the drilling rig power head with the drill pipe...

Embodiment 3

[0106] This embodiment provides a method for repairing rods with the automatic rod adding device for the coal mine underground tunnel drilling rig in Embodiment 1, which specifically includes the following steps:

[0107] Step 1, when it is necessary to fill the drill pipe chamber with drill pipes, operate the extended and ejected oil cylinder, the inner chamber rotates around the pin shaft, and the upper opening of the inner chamber is completely exposed;

[0108] Step 2, manually fill the drill pipe in the inner chamber;

[0109] Step 3: Operate the retraction and push-out oil cylinder, and the drill pipe inner chamber rotates around the pin shaft and returns to the outer chamber, and maintains a vertical state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com