Method for determining antimony in lead bullion by precipitation separation-carbon reduction cerium sulfate volumetric method

A technology of precipitation separation and cerium sulfate, which is applied in the direction of chemical analysis by titration, can solve the problems of narrow linear range, difficult to distinguish titration end point, high matrix, etc., and achieve the effect of improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

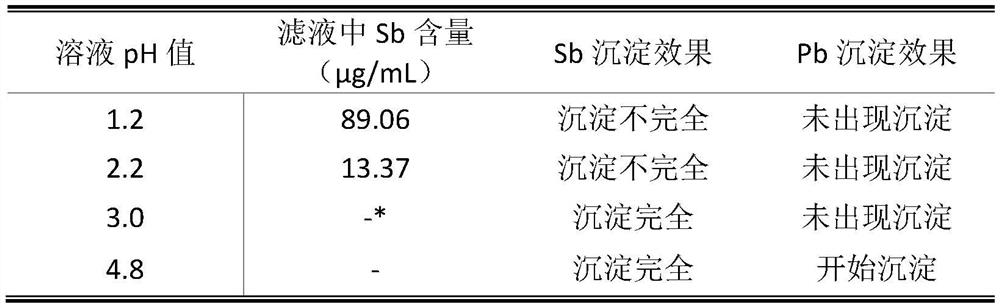

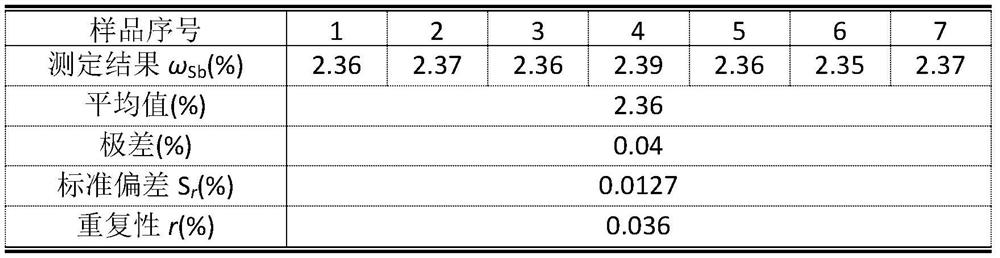

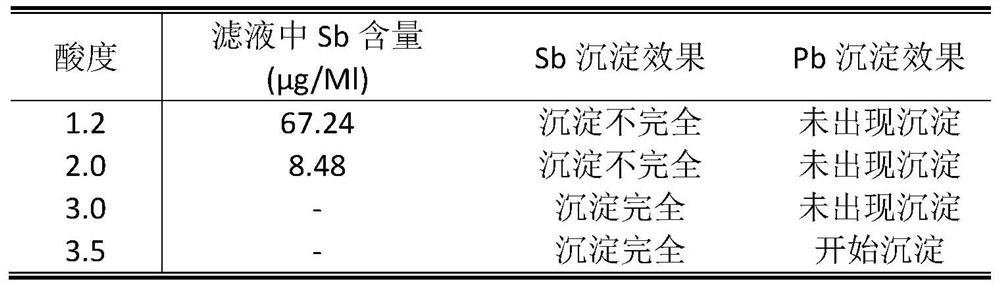

Method used

Image

Examples

Embodiment 1

[0047] A method for the determination of antimony in crude lead by precipitation separation-carbon reduction cerium sulfate volumetric method, it comprises the following steps:

[0048] Step 1. Preparation of cerium sulfate standard solution: Weigh 10g of cerium sulfate and place it in a 1000mL beaker, add 30mL of sulfuric acid, mix well, and gradually heat up on the electric furnace until the cerium sulfate dissolves into a paste and gradually emits white smoke of sulfuric acid for about 30min. Remove and cool slightly, add 140mL of sulfuric acid solution with a concentration of 50% by volume, then slowly add 400mL of water, stir and dissolve until the solution is clear, cool, and dilute to a 1000mL volumetric flask with water to obtain a molar concentration of 0.025mol / L of cerium sulfate standard solution;

[0049] Step 2. Calibration of metal antimony by cerium sulfate standard solution: Weigh 4 parts of 0.060g metal antimony, the mass percentage of metal antimony is ≥99....

Embodiment 2

[0074] A method for the determination of antimony in crude lead by precipitation separation-carbon reduction cerium sulfate volumetric method, it comprises the following steps:

[0075]Step 1. Preparation of cerium sulfate standard solution: Weigh 10g of cerium sulfate and place it in a 1000mL beaker, add 30mL of sulfuric acid, mix well, and gradually heat up on the electric furnace until the cerium sulfate dissolves into a paste and gradually emits white smoke of sulfuric acid for about 30min. Remove and cool slightly, add 140mL of sulfuric acid solution with a concentration of 50% by volume, then slowly add 400mL of water, stir and dissolve until the solution is clear, cool, and dilute to a 1000mL volumetric flask with water to obtain a molar concentration of 0.025mol / L of cerium sulfate standard solution;

[0076] Step 2. Calibration of metal antimony by cerium sulfate standard solution: Weigh 4 parts of 0.060g metal antimony, the mass percentage of metal antimony is ≥99.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com