Standing method for self-discharge detection of lithium ion battery

A lithium-ion battery, self-discharge technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of high static cost, abnormal battery leakage detection, abnormal battery self-discharge, etc., and achieve high efficiency and short screening time The effect of segment and screening accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

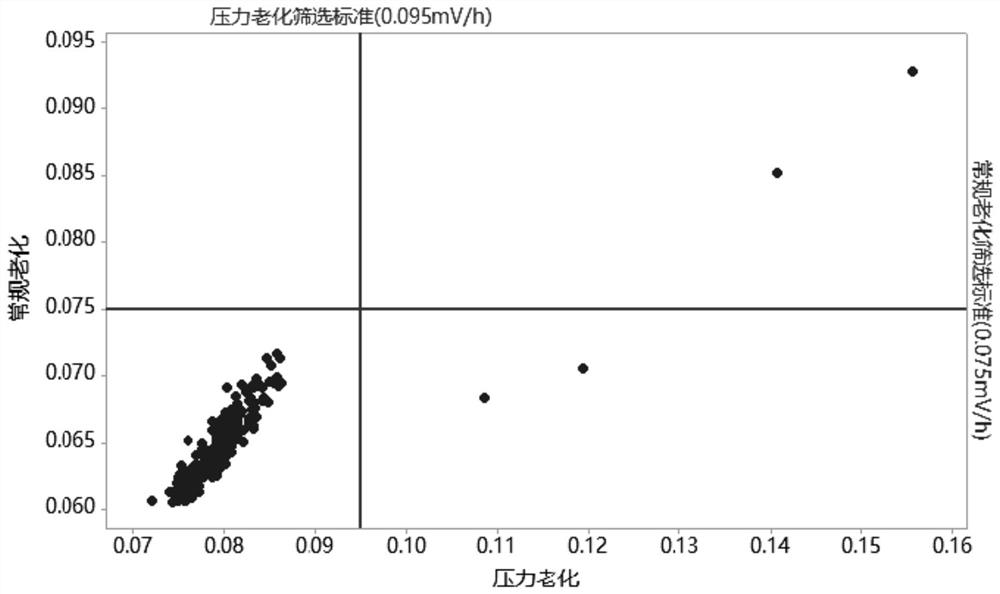

[0049] Such as figure 2 As shown, take 500 soft-pack batteries of a certain type with a capacity of 52Ah, charge them to 60% SOC first, and test the self-discharge rate of the batteries in the natural state with the conventional static process. After the test, use the same battery, charge it to the same 60% SOC, and apply 22kg / cm2 to the battery 2 The pressure, and then test the self-discharge rate in the pressurized state. Except whether the battery is under pressure or not, other influencing factors such as SOC, resting time, resting temperature, resting place, and measuring instruments during the two tests remain unchanged. , compare the two self-discharge data and disassemble and analyze the abnormal battery. The specific test process is as follows:

[0050]Routine process: charge the battery to 60% SOC → complete a voltage screening on the charging and discharging equipment → place the battery in a static basket → stand at a high temperature of 45±3°C for 24 hours → st...

Embodiment 2

[0053] Such as image 3 As shown, through the process of this method, select 800 batteries, charge the battery with 60% SOC → complete a voltage screening on the charging and discharging equipment → apply 15kg / cm to the battery 2 The pressure → high temperature 30 ℃ for 12 hours → normal temperature 25 ℃ for 12 hours → measure the first open circuit voltage of the battery and record the time → normal temperature 25 ℃ for 12 hours → measure the second open circuit voltage of the battery and record the time. The screening rate obtained through the steps of this embodiment is 100%.

Embodiment 3

[0055] Such as Figure 4 As shown, through the process of this method, select 1000 batteries, charge the battery with 60% SOC → complete a voltage screening on the charging and discharging equipment → apply 15kg / cm to the battery 2 The pressure → high temperature 40 ℃ for 12 hours → normal temperature 12 ℃ for 10 hours → measure the first open circuit voltage of the battery and record the time → normal temperature 12 ℃ for 12 hours → measure the second open circuit voltage of the battery and record the time. The screening rate obtained through the steps of this embodiment is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com