Modeling method of gradient porous structure based on STL file

A gradient porous, modeling method technology, applied in the field of 3D modeling, to achieve the effect of simple and efficient modeling method, easy to understand and master, and realize the effect of adjustment range and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

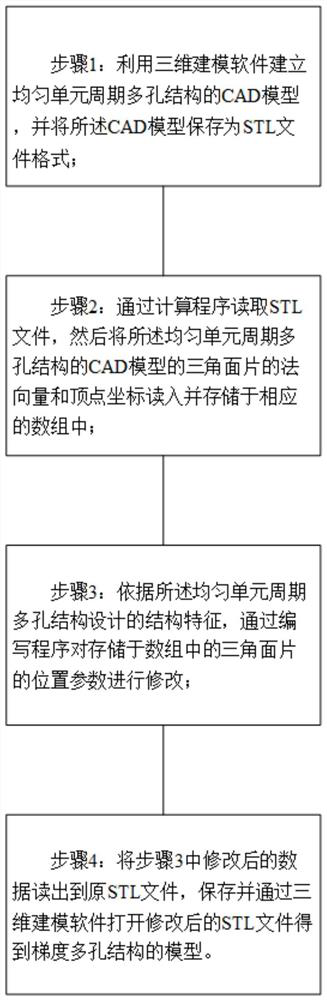

Method used

Image

Examples

Embodiment 1

[0042]Establish a CAD model of the uniform periodic porous structure of the diamond unit, and design the overall appearance structure of the model as a frustum shape, with a radius of 5 on the upper surface, a radius of 6.7 on the lower surface, and a height of 10 frustum. The CAD model size of a single diamond unit is 2×2×2, where the porosity of a single unit is 50%. Since it is a unit periodic porous structure, the overall porosity of the porous structure CAD model is 50%. After the modeling is completed, it is saved as an STL file in ASCII file format.

[0043] The STL file is read in through a calculation program, and the direction vector and vertex coordinate data of the triangular surface of the porous structure CAD model are sequentially read, and the read data are processed. Specifically, by modifying the position parameters, the distance between the diamond unit brackets is reduced, so that the aperture size of the structure is reduced, and the aperture size of the eq...

Embodiment 2

[0047] Establish the CAD model of the uniform periodic porous structure of the diamond unit. The overall appearance of the model is cylindrical, the radius of the upper surface circle is 5, and the height of the cylinder is 10. The porosity of the unit is 50%, and since it is a unit periodic porous structure, the overall porosity of the porous structure is 50%. After the modeling is completed, save it as an STL file in ASCII file format.

[0048] The STL file is read in through a calculation program, and the direction vector and vertex coordinate data of the triangular surface of the porous structure CAD model are sequentially read, and the read data are processed. Specifically, by modifying the position parameters, the distance between the diamond unit brackets is reduced, so that the aperture size of the structure is reduced, and the aperture size of the equal height is kept consistent. direction, the aperture decreases continuously from top to bottom.

[0049] After the p...

Embodiment 3

[0052] For porous structures of other unit types, such as helical tetrahedral unit, tetrahedral unit, hexahedral unit, octahedral unit, etc., the CAD model of helical tetrahedral unit is given, and its operation process is the same as in Example 1 and Similar to Example 2, only the structure type of the porous structure is different, and the gradient porous structure with the porosity change of the unit type can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com