A kind of high reflectivity black solar battery back plate and preparation method thereof

A technology of solar cells and high reflectivity, applied in the field of solar cells, can solve problems such as potential safety hazards and low photoelectric conversion efficiency, and achieve the effects of improving production efficiency, simple and efficient preparation methods, and convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

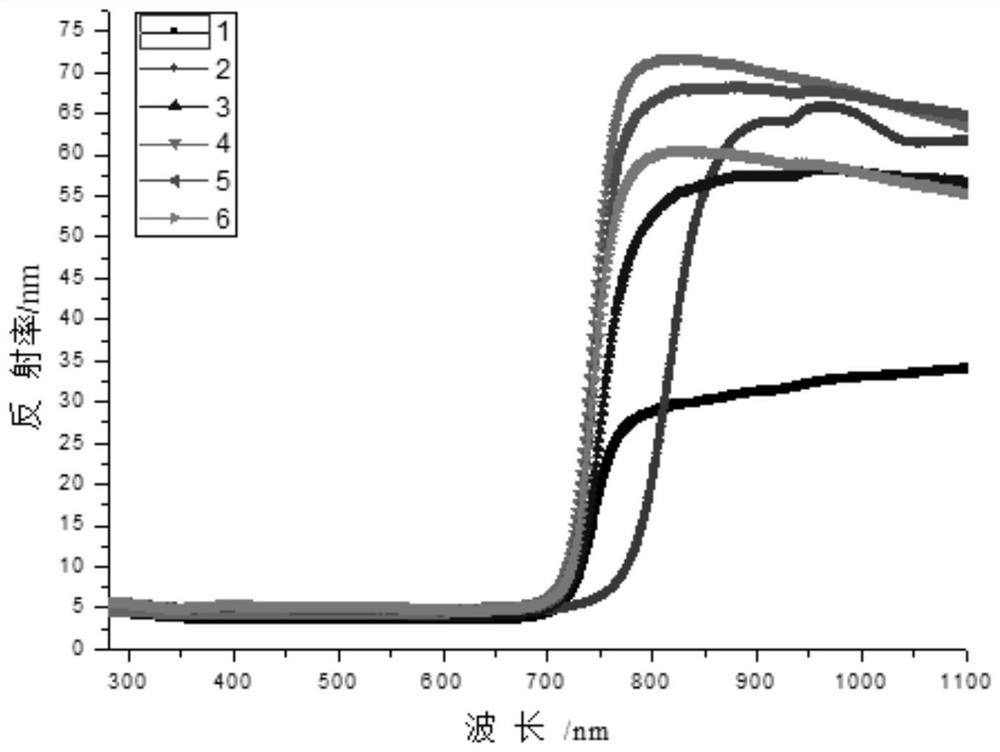

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

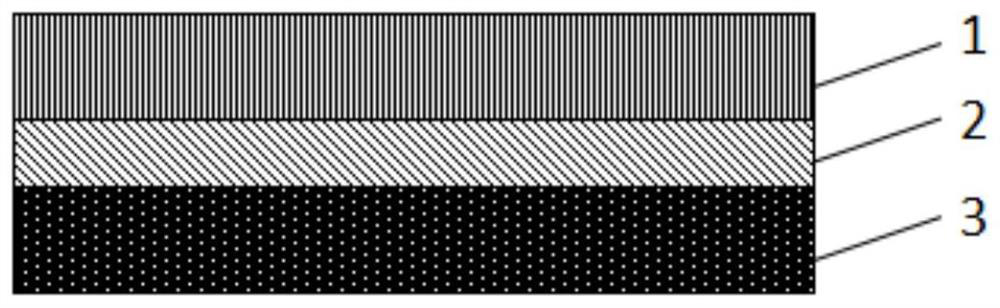

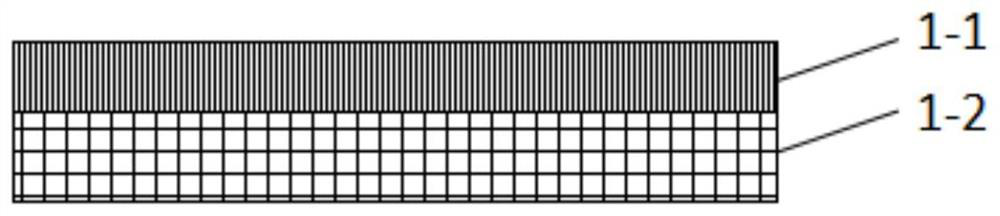

[0050] A high-reflectivity black solar battery backsheet, comprising a weather-resistant layer 1, an adhesive layer 2, and a black reflective layer 3 arranged sequentially from top to bottom, the thickness of the black reflective layer 3 is 20 μm, and the black reflective layer 3 Comprising the following raw materials in parts by weight:

[0051] 20 parts of the first polyolefin resin

[0052] 15 parts of the first bonding resin

[0053] 10 parts of black functional masterbatch.

[0054] Each part of the black functional masterbatch includes the raw materials of the following parts by weight:

[0055] 5 parts of the second polyolefin resin

[0056] 5 parts of the second adhesive resin

[0057] 40 parts of black additives.

[0058] Each part of the first polyolefin resin is a mixture of polyethylene, cross-linked polyethylene and ethylene-propylene copolymer in a weight ratio of 0.8:0.6:0.4.

[0059] Each part of the second polyolefin resin is a mixture of polyethylene, c...

Embodiment 2

[0077] A high-reflectivity black solar cell backsheet, comprising a weather-resistant layer 1, an adhesive layer 2 and a black reflective layer 3 arranged in sequence from top to bottom, the thickness of the black reflective layer 3 is 102 μm, and the black reflective layer 3 Comprising the following raw materials in parts by weight:

[0078] The first polyolefin resin 38 parts

[0079] 33 parts of the first bonding resin

[0080] 13 parts of black functional masterbatch.

[0081] Each part of the black functional masterbatch includes the raw materials of the following parts by weight:

[0082] 10 parts of the second polyolefin resin

[0083] 10 parts of the second bonding resin

[0084] 54 parts of black additives.

[0085] Each part of the first polyolefin resin is a mixture of polyethylene, cross-linked polyethylene and ethylene-propylene copolymer in a weight ratio of 0.9:0.7:0.5.

[0086] Each part of the second polyolefin resin is a mixture of polyethylene, chlorin...

Embodiment 3

[0104] A high-reflectivity black solar cell backsheet, comprising a weather-resistant layer 1, an adhesive layer 2, and a black reflective layer 3 arranged sequentially from top to bottom, the thickness of the black reflective layer 3 is 185 μm, and the black reflective layer 3 Comprising the following raw materials in parts by weight:

[0105] The first polyolefin resin 55 parts

[0106] 51 parts of the first bonding resin

[0107] 17 parts of black functional masterbatch.

[0108] Each part of the black functional masterbatch includes the raw materials of the following parts by weight:

[0109] 15 parts of the second polyolefin resin

[0110] 15 parts of the second bonding resin

[0111] 65 parts of black additives.

[0112] Each part of the first polyolefin resin is a mixture of polyethylene, cross-linked polyethylene and ethylene-propylene copolymer in a weight ratio of 1.0:0.8:0.6.

[0113] Each part of the second polyolefin resin is a mixture of polyethylene, chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com