Compound combined reel

A winding wheel and compound technology, applied in the field of compound combined winding wheels, can solve the problems of reduced work quality, low working time, and unfavorable safety guarantees, so as to improve the standardization of work, save equipment operating costs, and facilitate maintenance and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is one of the preferred embodiments of this patent:

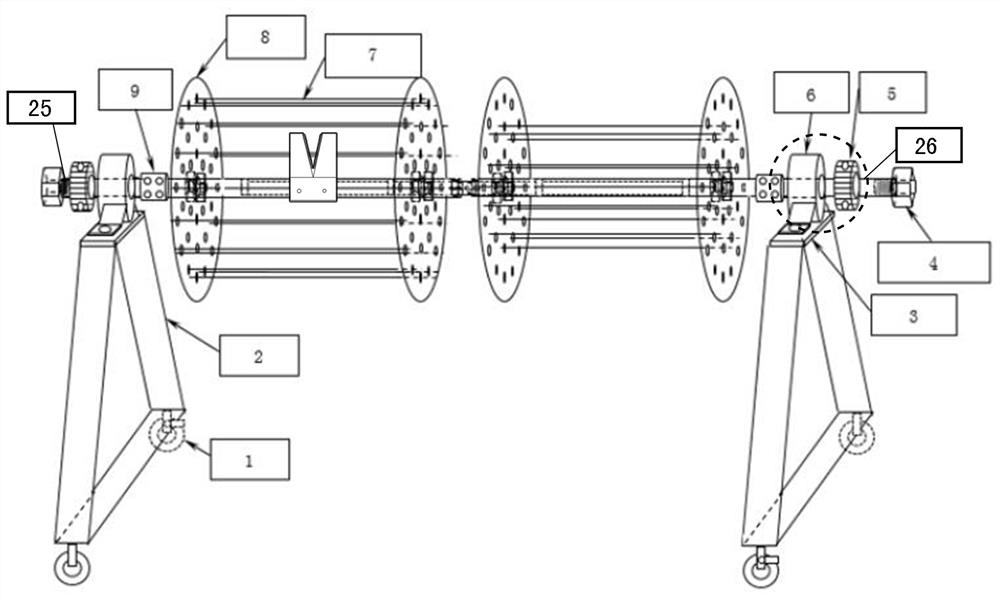

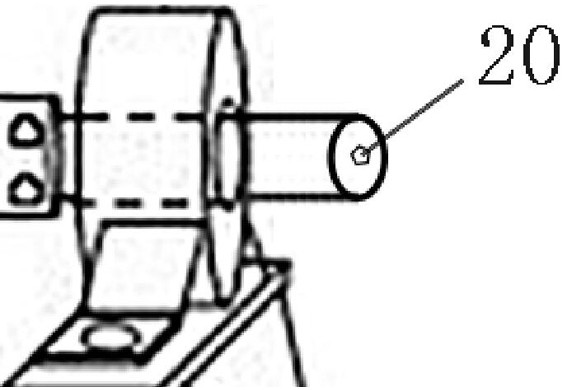

[0044] Refer to attached figure 1 , shows a composite combined reel, including two bottom supports, the top surface of the bottom support is detachably installed with a bearing seat, a coupling shaft is erected between the two bearing seats, and the coupling shaft and the bearing seat rotate in cooperation, and the two ends of the coupling shaft Protrude out of the bearing seat, the two ends of the coupling are detachably installed with hexagonal nuts and gears, and the detachable sleeves on the coupling are equipped with two pairs of turntables, and a plurality of winding posts are set up between each pair of turntables, and the winding posts go around the turntable Centrally symmetrical layout.

[0045] The bottom support is a trapezoidal support formed by welding stainless steel plates, and the bottom is provided with running wheels.

[0046] The coupling is composed of the first rotating shaft, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com