A special binder for glass-ceramics

A glass-ceramic and binder technology, applied in the field of building materials, can solve the problems of VOC emission affecting the indoor environment, difficulty in achieving the same life of buildings, powdering of the surface of glass-ceramic, etc., achieving high construction efficiency, low cost, Good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

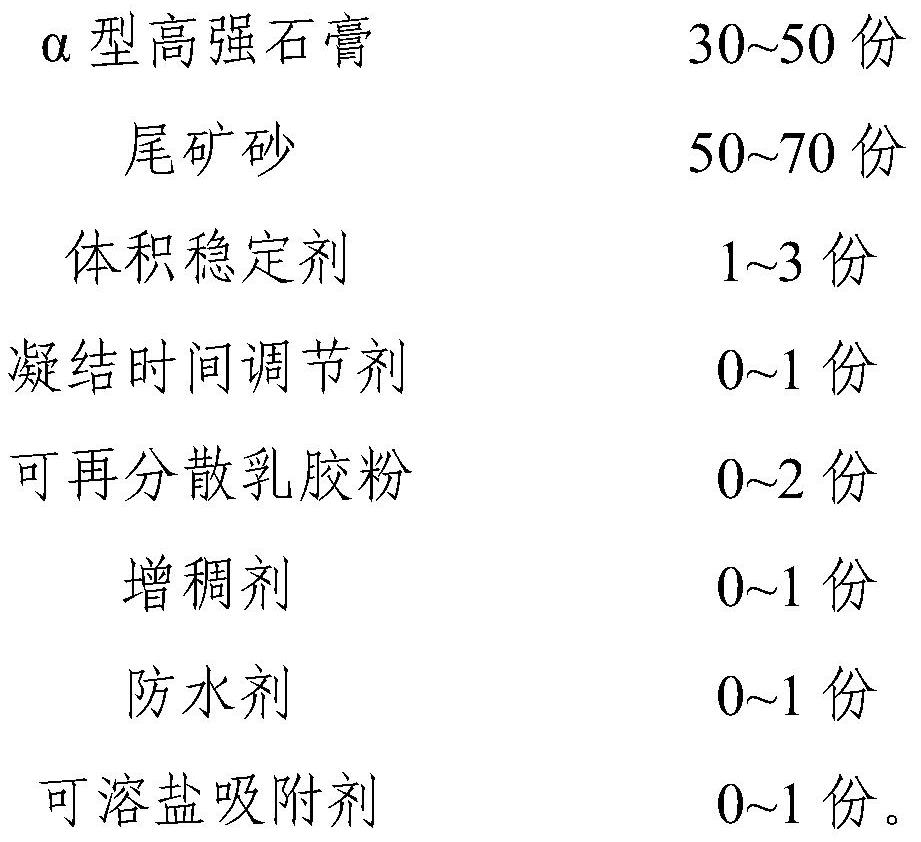

[0048] This embodiment provides a special binder of a microcrystalline glass comprising a component of the following weight:

[0049]

[0050] Among them, the α-type high-strength gypsum is from industrial by-production plaster in a saturated water vapor medium, dissolved and recrystallized by 4 h; the dry compressive strength is 50 MPa, and the particle size is 0.1 to 100 μm, and the average particle size is 12 ~ 15μm;

[0051] The volume stabilizer is a mixture of tartaric acid and the type II water-resistant gypsum by mass than 1:50;

[0052] Among the molybdenum tailings, a particle size of 100 to 1000 μm accounted for 40%, and a particle diameter of 10 to 100 μm accounted for 60%.

Embodiment 2

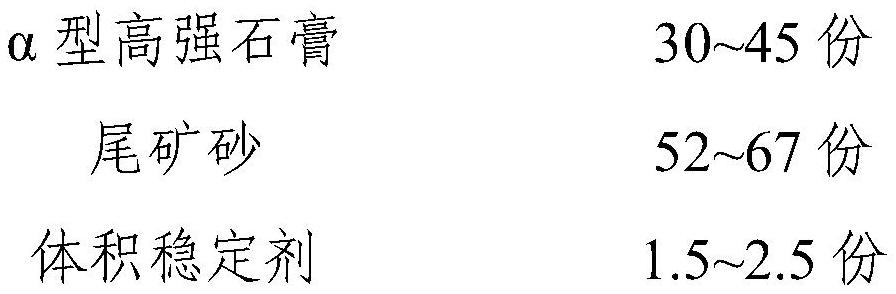

[0054] This embodiment provides a special binder of a microcrystalline glass comprising a component of the following weight:

[0055]

[0056] Wherein, the α-type high-strong gypsum has a dry anti-pressure strength of 50 MPa, and the particle size is 0.1 to 100 μm, and the average particle diameter is 12 to 15 μm;

[0057] The volume stabilizer is a mixture of tartaric acid and the type II water-resistant gypsum by mass than 1:50;

[0058] Among the molybdenum tailings, a particle diameter accounted for 45%, a particle diameter of 10 to 100 μm accounted for 55%.

Embodiment 3

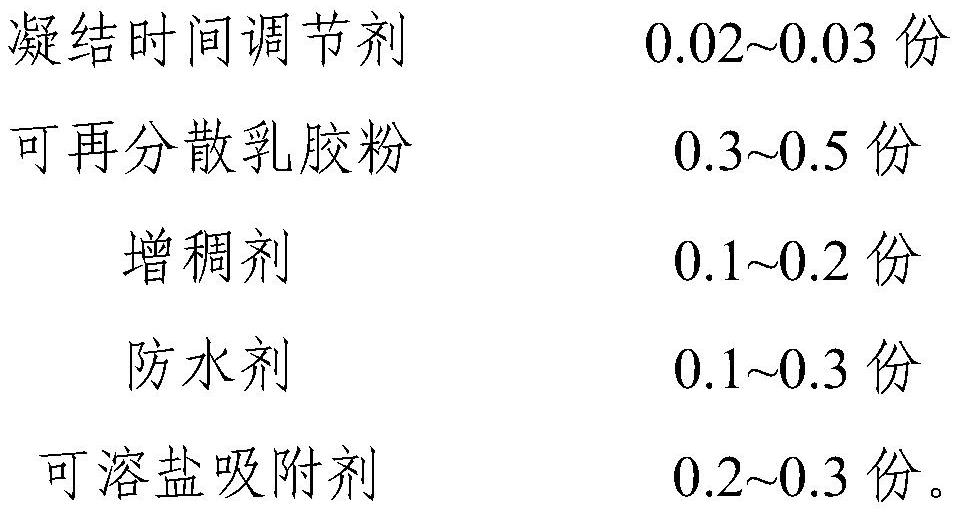

[0060] This embodiment provides a special binder of a microcrystalline glass comprising a component of the following weight:

[0061]

[0062]

[0063] Among them, the dry anti-pressure strength of the α-type high-strong gypsum is 45 MPa, 0.1 to 80 μm, and average particle size of 10 to 12 μm;

[0064] The volume stabilizer is a mixture of tartaric acid and the type II water-resistant gypsum by mass than 1:50;

[0065] Among the molybdenum tailings, a particle diameter accounted for 42%, a particle size of 10 to 100 μm accounted for 58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com