Pressure-bonding hydrogenation method

A pressure and highest pressure technology, applied in the direction of pressure vessels, container filling methods, container discharge methods, etc., can solve problems such as machine loss, unsatisfactory hydrogenation equipment, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

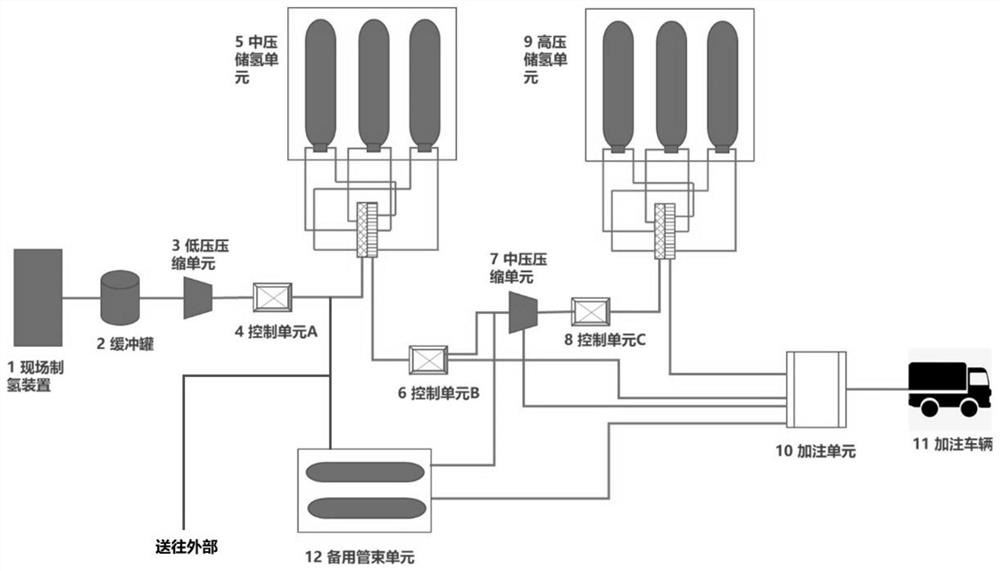

[0102] Example 1 uses figure 1 The arrangement structure of each component is shown, wherein the on-site hydrogen production device 1 is an electrolytic hydrogen production device capable of producing hydrogen at a pressure of about 2 MPa, the rated hydrogen production is about 500 kg / day, and the hydrogen is produced after passing through the low-pressure compression unit 3. Pressurized hydrogen, the medium-pressure hydrogen storage unit 5 includes nine units with a volume of 0.5m 3 The preset filling pressure of each gas storage cylinder is 20MPa; the hydrogen gas generates 45MPa high-pressure hydrogen after passing through the medium-pressure compression unit 7, and the high-pressure hydrogen storage unit 9 includes nine cylinders with a volume of 0.5m 3 The preset filling pressure of each gas storage cylinder is 45MPa; the spare tube bundle unit 12 includes three volumes of 0.5m 3 The preset filling pressure of each gas cylinder is 20MPa.

[0103] In this embodiment 1, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com