Controllable light beam diverter based on phase-change material

A technology of phase change material and diverter, applied in instruments, optics, nonlinear optics, etc., can solve the problems of aluminum melting, device polarization sensitivity, and large phase change material layer area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

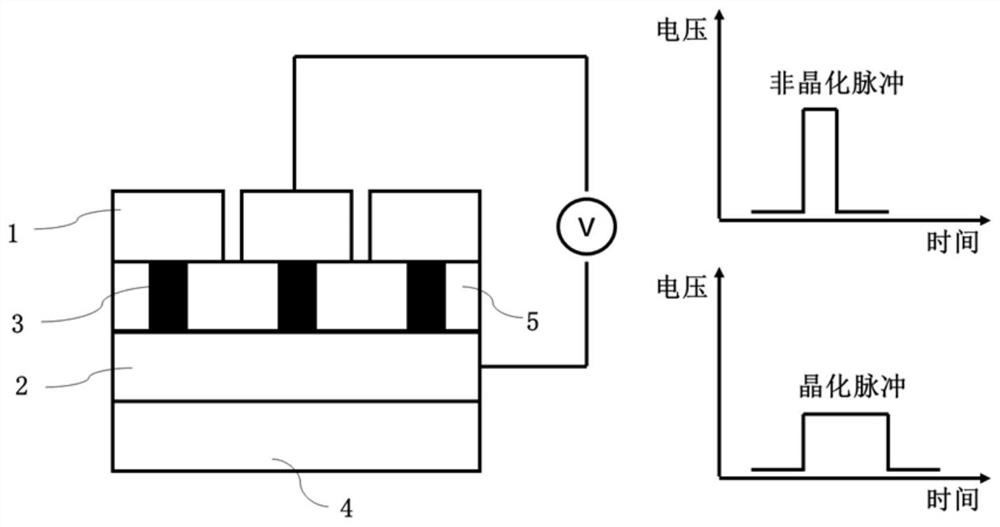

[0021] With silicon dioxide as the substrate, it is mainly composed of three parts: the lower electrodes arranged in parallel in the horizontal direction, the phase change material layer in the cross region, and the upper electrode layer arranged in the vertical direction. The upper and lower electrodes are separated by silicon dioxide. First deposit a layer of ITO on the silicon dioxide substrate, and use electron beam exposure and etching process to form the lower electrode arranged laterally; then deposit the silicon dioxide layer and perform etching to form the phase change material through hole; then deposit the phase change material , to planarize the surface; then deposit a layer of ITO on the surface, and form vertically arranged upper electrodes by electron beam exposure and etching.

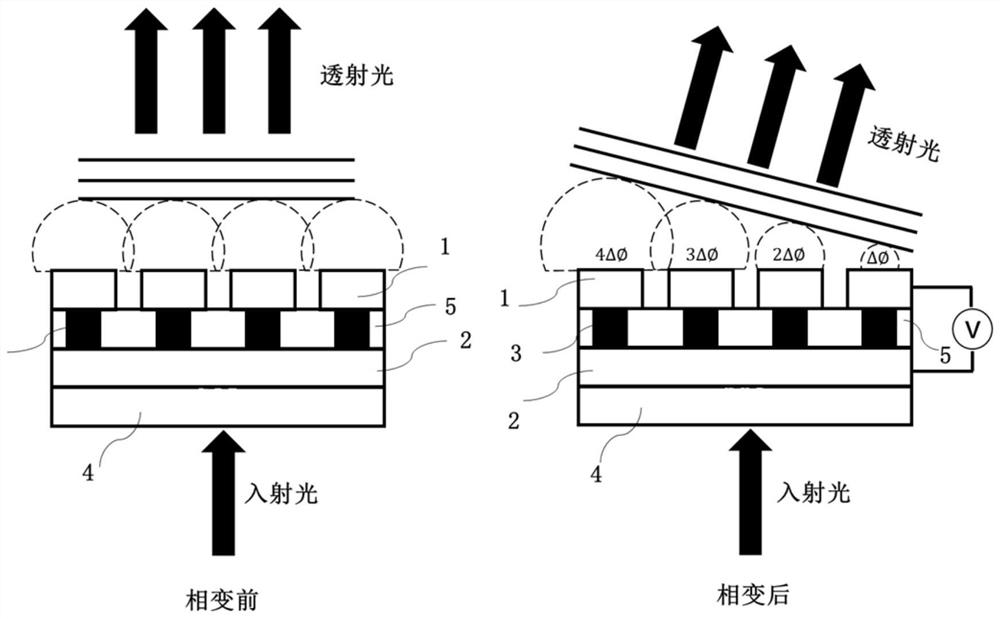

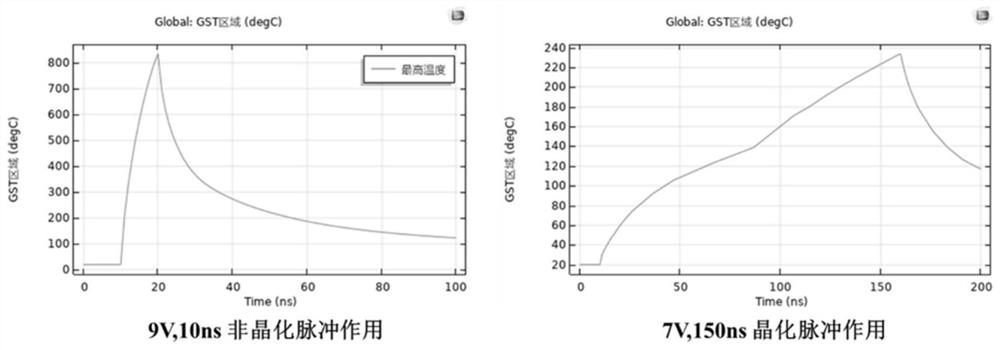

[0022] figure 2 It is a schematic diagram of the working principle of the device structure of the present invention. The light beam is incident from below the silicon dioxide substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com