Workbench for quick-cooling laser marking machine

A laser marking machine and workbench technology, which is applied in the field of laser marking machines, can solve the problems of affecting the operation process, high surface temperature, and temperature drop, and achieve the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

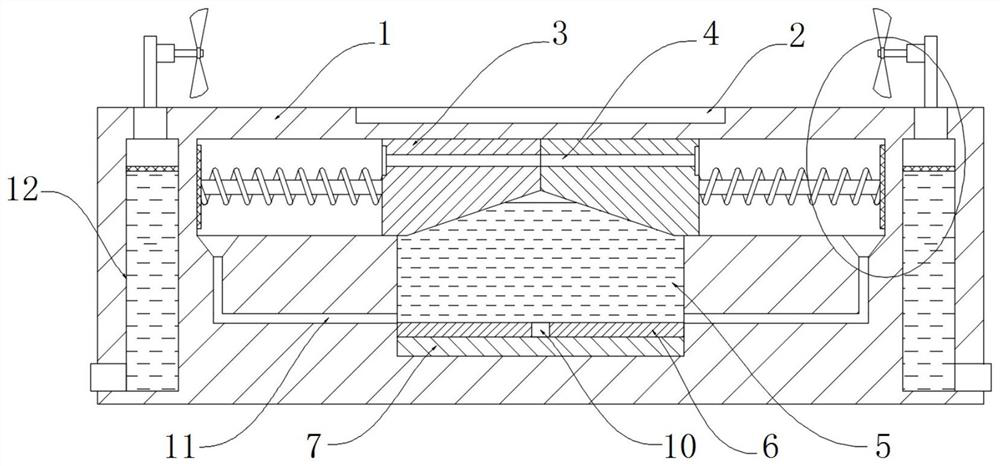

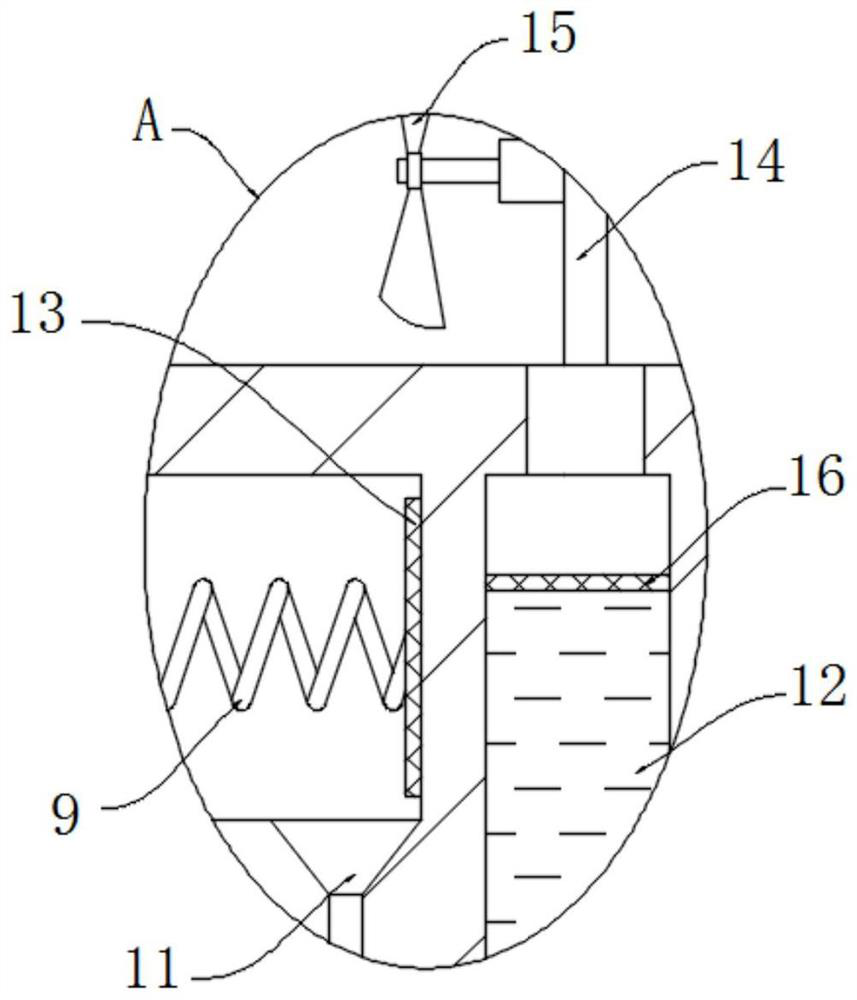

[0020] refer to Figure 1-2 , a workbench for a quick-cooling laser marking machine, including a fixed seat 1 and a positioning groove 2 set on the top of the fixed seat 1, a cavity 5 with a T-shaped structure is opened in the fixed seat 1, and the cavity 5 is sealed and slid Two opposite wedge-shaped blocks 3 are connected, the sides of the two wedge-shaped blocks 3 away from each other are respectively fixedly connected with springs 9, the bottom of the cavity 5 is fixedly connected with an electromagnet 7, and the electromagnet 7 is opposed to a sealing plate 6 with a permanent magnet structure , the electromagnet 7 is opposite to the magnetic pole of the sealing plate 6, and a return hole 10 is opened through the sealing plate 6, and a check valve is sealingly connected to the return hole 10;

[0021] The cooling liquid with a boiling point of 70°C is installed in the cavity 5 above the sealing plate 6, and the wedge block 3 is made of heat insulating material, so that whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com