Foaming preheating device for strip-shaped high polymer material

A technology of polymer material and preheating device, which is applied to belts, other household appliances, household appliances, etc., can solve the problems of unbalanced force on both sides of the gears, prone to broken teeth or skipped teeth, and reduced production efficiency. failure, improving the preheating effect, and improving the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

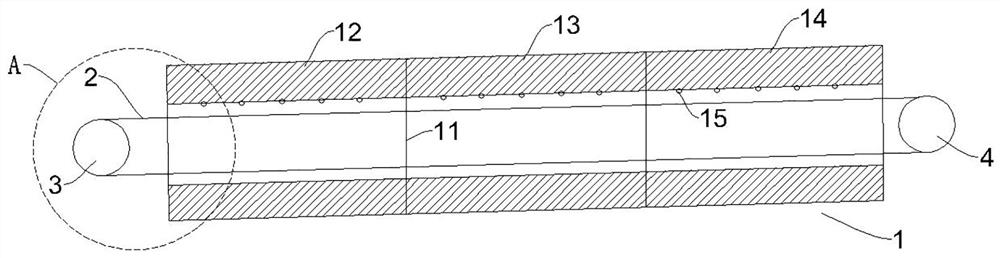

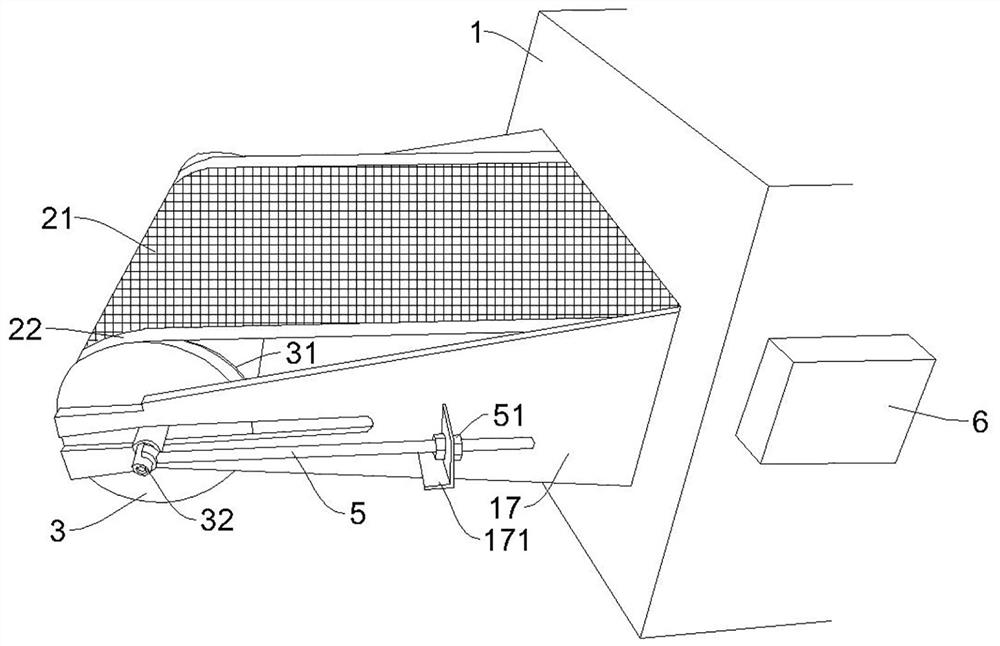

[0027] A foaming preheating device for strip-shaped polymer materials, such as Figure 1~2 As shown, it includes a heating box 1 and a conveying mechanism that transports the strip-shaped polymer material to the heating box 1;

[0028] The conveying mechanism includes a closed-loop conveyor belt 2 that is arranged in the heating box 1 and extends to the outside of the inlet of the heating box 1 with one end, and a first roller that is wound around both ends of the conveyor belt 2 cylinder 3 and second roller 4, the first roller 3 is located outside the inlet end of the heating box 1, and the second roller 4 is located outside the outlet end of the heating box 1, and the first roller 3 and the second roller 4 At least one of them is a driving roller driven by power equipment (the second roller 4 in this embodiment is a driving roller, which is driven by a motor to rotate); the conveyor belt 2 is made of flexible polymer materials, including grid-shaped The shelving area 21 of ...

Embodiment 2

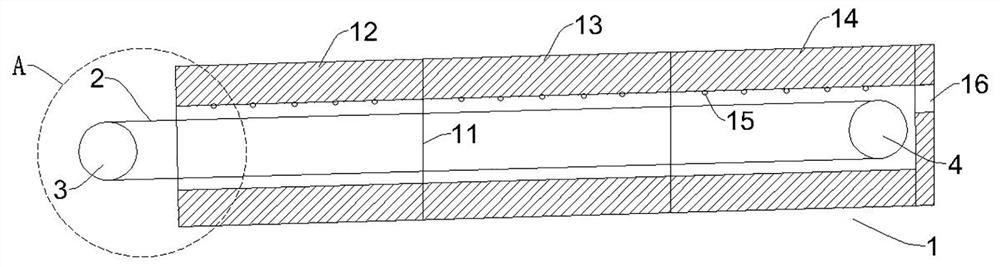

[0034] A foaming preheating device for strip-shaped polymer materials, the basic structure is the same as that of Embodiment 1, the difference is that: the second roller 4 is located near the outlet end inside the heating box 1, and the upper position of the outlet end of the heating box 1 is set There is an air outlet 16, and the rest of the positions are closed and arranged. After the sheet is preheated, it is sent out from the air outlet 16, and the waste gas generated during the preheating process is also sent out from the air outlet 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com