Preparation method of hydrogen-infiltration-resistant surface in situ nanocrystallized bainitic steel

A kind of bainitic steel and nanotechnology, applied in the field of surface in-situ nanotechnology, can solve the problems of high delayed fracture resistance, low hydrogen embrittlement sensitivity, etc., and achieve the effects of strengthening the surface, hindering hydrogen infiltration, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The chemical composition (wt%) of the base steel is: C0.30, Mn2.2, Al0.98, Cr1.2, Ni0.23, Mo0.24, Si1.1, S0.0015, P0.006, and the rest is Fe .

[0037] The preparation method is:

[0038] S1: Heat the base steel to 920°C and keep it warm for 40 minutes;

[0039] S2: Put the heated and heat-preserved base steel at 350°C for salt bath treatment and heat-preserve for 1.5 hours, then air-cool;

[0040]S3: Process the base steel after air-cooling treatment into a rolling contact sample. The sample is a ring with an outer diameter of 80mm, an inner diameter of 60mm, and a thickness of 8mm. The sample is tested on an online rolling contact fatigue testing machine. The experimental environment is room temperature. Air environment; the contact stress is 1700MPa, the slip rate is 3%, the speed is 800rpm, and the operation cycle is 1.0×10 6 Week.

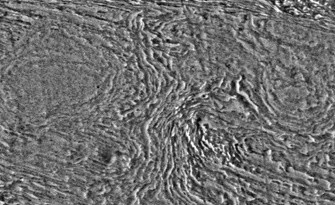

[0041] Cut the surface sample of the sample, and use the scanning electron microscope to observe the microstructure, such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com