Plugging and building method suitable for remaining mine tunnel and mine underground tunnel

A technology of tunnels and mines, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve problems such as emissions, and achieve the effects of preventing oxidation, inhibiting oxidation, and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A plug suitable for legacy mines and mine tunnels.

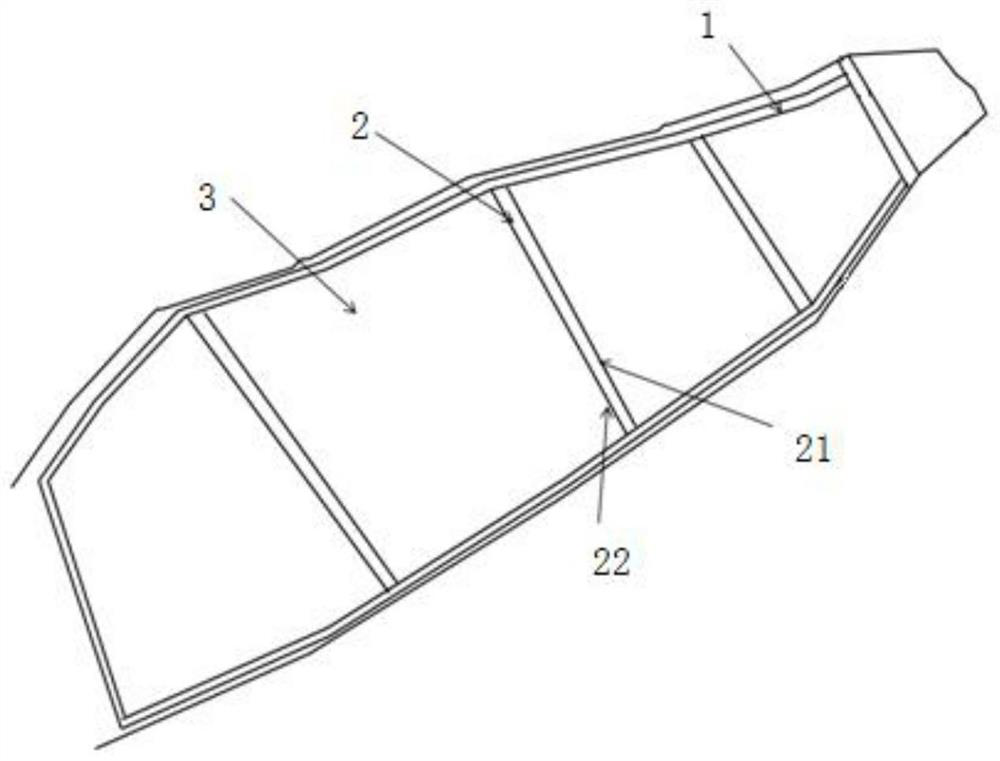

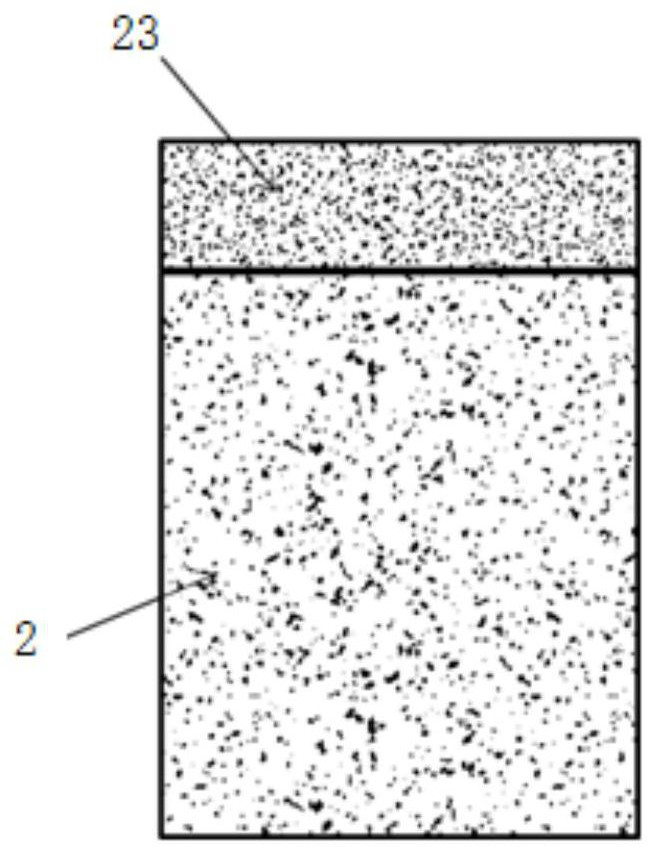

[0042] refer to Figures 1 to 2 , the plugging includes a side interlayer wall 1 which is parallel to the side wall of the leftover mine or mine tunnel. The side interlayer wall 1 is provided with an interlayer space, and the interlayer space is filled with hydrophobic granular materials, and the upper end It extends to the top of the leftover mine or the mine tunnel to form a closed space to prevent the loss of hydrophobic granular materials, thereby ensuring the anti-seepage function of the interlayer wall.

[0043]The above-mentioned confined space is provided with a number of spaced interlayer walls 2 from the inside to the outside to the opening, so as to divide the confined space into four segmented filling units 3 . Interlayer spaces are also provided in the interlayer wall 2, and the interlayer spaces are filled with hydrophobic granular materials. Each segmented filling unit 3 is filled with hydrophobic gra...

Embodiment 2

[0049] This embodiment is a construction method suitable for the plugging of legacy mines and mine tunnels. This method is used to build the plugging of legacy mines and mine tunnels described in Example 1, which includes the following steps:

[0050] Step 1: Clean up the gravel inside the remaining mines and mine tunnels, level the bottom of the mines and tunnels, and determine the blockage area;

[0051] Step 2: Considering the lateral water seepage of the remaining mines and mine tunnels, build side interlayer walls 1 near the side walls in the mine caves and tunnel sealing areas;

[0052] Step 3: Fill the interlayer space of the side interlayer wall 1 with hydrophobic granular materials. After filling, build the side interlayer wall 1 to the top of the left mine or mine tunnel to form a closed space to prevent hydrophobic loss of particulate matter;

[0053] Step 4: The confined space is provided with a number of spaced interlayer walls 2 from the inside to the outside to...

Embodiment 3

[0060] For mines left over from the mining of sulfur-containing copper mines, in order to prevent water and oxygen from entering the mines and achieve the purpose of blocking the sulfide oxidation path, the following methods are adopted.

[0061] Step 1: Clean up the gravel inside the left mine, level the bottom, select the tunnel area with a length of 36m close to the mine after cleaning as the plugging area, the inner width of the area is 2.5-10.0m, the width of the entrance is 6.5m, and the height of the tunnel is 1.5~2.4m;

[0062] Step 2: In consideration of the lateral seepage of groundwater, a side interlayer wall 1 is installed on the inner side wall of the mine, and an interlayer interlayer wall 2 is built in the closed area near the inner end of the tunnel. The total length of the two walls is 81m, and the side interlayer The distance between the interlayers of the wall 1 is 8cm, and the thickness of the interlayer is 15cm, which is composed of cement and sandstone; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com