FRP rib compression load holding and testing device and operation method thereof

A technology for testing devices and steel bars, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of few studies on the durability of FRP bars, achieve simple structure, reduce space, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

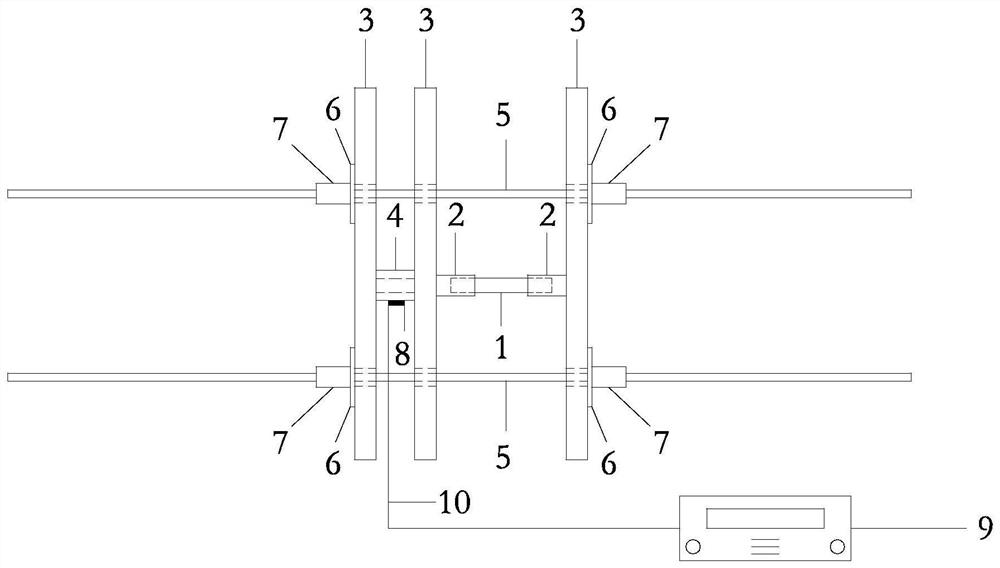

[0029] like figure 1 As shown, the present invention is used as a pressure-bearing device for FRP bars, including FRP bars 1, bonded sleeves 2, square steel plates 3 (including left steel plates, middle steel plates, and right steel plates), circular sleeves 4, and prestressed steel plates. Finished threaded steel bars 5, steel washers 6, finished nuts 7, strain gauges 8, resistance strain gauges 9, and connecting wires 10. There are two bonding sleeves 2, which are respectively fixed on the two ends of the FRP tendon 1 by potting glue.

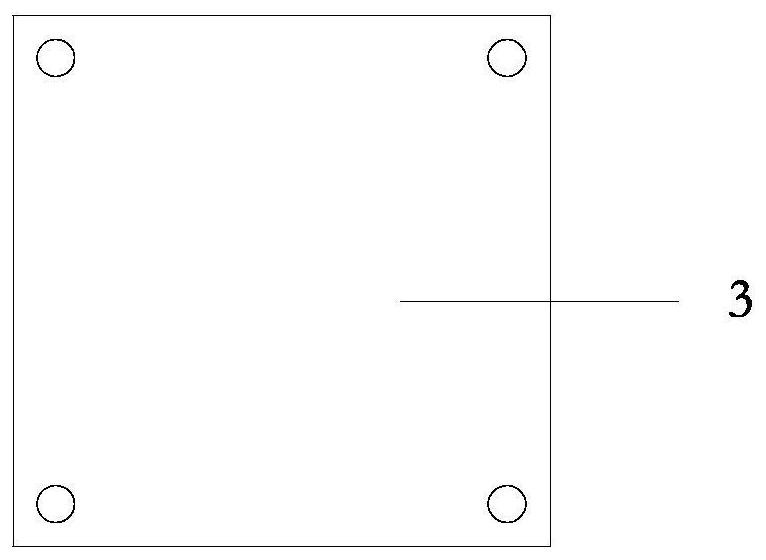

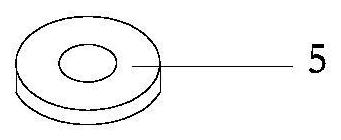

[0030] like figure 2 As shown, the square steel plate 3 has three pieces, which are respectively arranged at both ends of the device and between the bonding sleeve 2 and the round sleeve 4, and four circular reserved holes are arranged at the four corners of the steel plate; the inside and outside of the round sleeve 4 The uniform light circle is arranged between the left and middle square steel plates 3, and is used as a load sensor by pa...

Embodiment 2

[0037] like Figure 5As shown, the FRP bar compression performance test device includes FRP bar 1, bonding sleeve 2, square steel plate 3, round sleeve 4, prestressed finish-rolled threaded steel bar 5, steel washer 6, finish-rolled nut 7, and strain gauges 8. Resistance strain gauge 9, connecting wire 10, puller 11. Take out the load-bearing device in the erosive environment simulation device, and add a square steel plate 3 and a puller 11 on the basis of the load-bearing device. The square steel plate 3 adds a new one, is arranged on the leftmost side of the device, and its left side is fixed with a steel washer 6 and a finishing nut 7; the drawing instrument 11 is arranged in the middle of the two leftmost square steel plates 3, Used to apply pressure.

[0038] The device for testing the compressive performance of FRP tendons is loaded by a puller 11 during the test, and the puller 11 pushes the square steel plate 3 on the right side to apply a force to the right, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com