Multilayer color code micro-marker capable of encoding information and preparation method thereof

A technology of information coding and markers, which is applied in the field of multi-layer color-coded micro-markers and preparations, can solve the problems of unclear marking patterns, easy manual replacement of labels, and limited application range, and achieve low prices, promote product production, The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides an information-encoded multi-layer color-coded micromarker, which includes micro-nano particles with more than three film layers, and the film layers include a resin matrix and dopants uniformly distributed in the resin matrix , the dopant includes one or more of fluorescent substances, magnetic substances or substances that can be attracted by magnetic substances, and pigments. Type and color encode information. Control the thickness and uniformity of different film layers, doping different functional substances such as magnetic materials or substances that can be attracted by magnetic substances, fluorescent agents, different colorants, etc., to obtain multi-layer uniform and color-coded micro-markers, Adjacent film layers cannot have the same color.

[0032] The above-mentioned multi-layer color-coded micro-marker is a colored mark with a multi-layer structure with specific functions realized by simulating the DNA coding mode by means of lay...

Embodiment 2

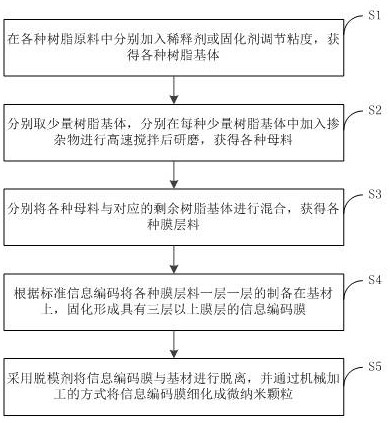

[0045] This embodiment provides a method for preparing an information-encoded multilayer color-coded micromarker, especially for preparing the information-encoded multilayered color-coded micromarker of Example 1, such as figure 1 shown, including the following steps:

[0046] S1. Add diluents or curing agents to various resin raw materials to adjust the viscosity to obtain various resin matrices;

[0047] S2. Take a small amount of the resin matrix respectively, add dopant to each small amount of resin matrix and grind at high speed to ensure that the particles are uniformly dispersed and equal in size to obtain various masterbatches. The dopant includes fluorescent One or more of substances, magnetic substances or substances that can be attracted by magnetic substances, and pigments;

[0048] Preferably, the fluorescent substances include but are not limited to fluorescein isothiocyanate, tetraethylrhodamine, tetramethylrhodamine isothiocyanate, phycoerythrin, europium-cont...

example 1

[0059] A method for preparing an information-encoded multilayer color-coded micromarker comprises the following steps:

[0060] Mix epoxy component A and component B (curing agent) with a volume ratio of 1:1 evenly, then add xylene in the same proportion to adjust the viscosity of the matrix. Take a small amount of prepared matrix resin, add 5% red pigment and 5% magnetic particles, stir at a high speed and then grind to obtain a uniform color masterbatch. Mix the color masterbatch with the rest of the base to prepare a red base for later use.

[0061] According to the same method, prepare substrates of yellow, black, green and other colors for later use.

[0062] Mix epoxy component A and component B (curing agent) with a volume ratio of 1:1 evenly, then add xylene in the same proportion to adjust the viscosity of the matrix. Take a small amount of prepared matrix resin, add 5% fluorescent substance and 5% magnetic particles, stir at high speed and then grind to obtain a un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com