Self-repairing adhesive tape for tire and preparation method thereof

A self-repairing and tire technology, applied in the field of tire rubber strips, can solve the problems of increasing manufacturing costs, not being environmentally friendly, and not improving the effect, and achieving the effects of improving mechanical properties, low air permeability, and good elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

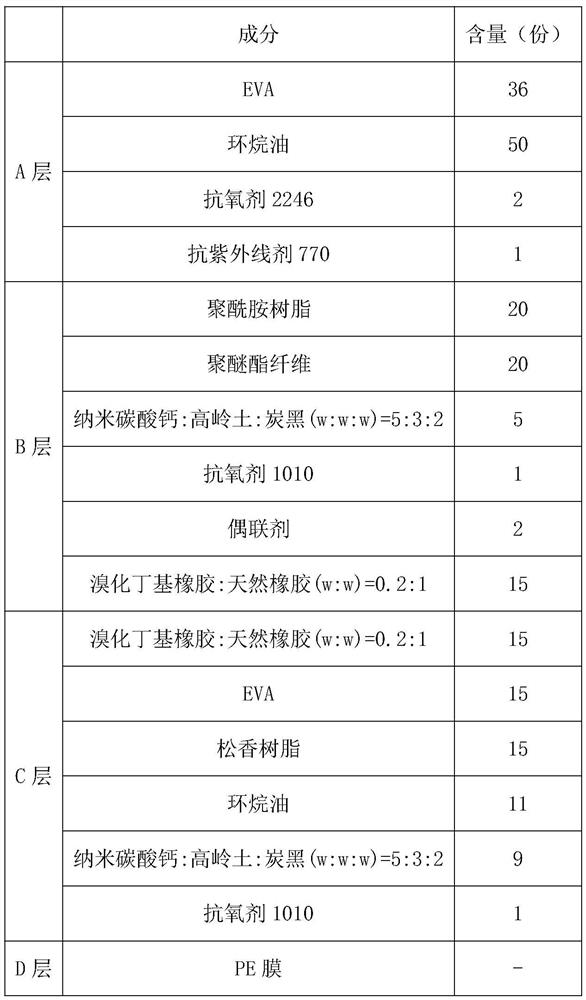

[0021] A tire self-repairing rubber strip according to the present invention has a formula shown in Table 1 below.

[0022] Table 1 A formula of tire self-repairing rubber strip

[0023]

[0024] A preparation method for a tire self-repairing rubber strip, comprising the steps of:

[0025] (1) Preparation of layer A: Add naphthenic oil, antioxidant 2246, and anti-ultraviolet agent 770 into the reaction kettle, react at 240°C for 2 hours, then add EVA, stir for 4 hours, and then discharge the material, and then use a coating machine to make a layer with a thickness of 2mm thick, 1.2m wide coils for use;

[0026] (2) Preparation of layer C: Heat the reaction kettle to 240°C, put in naphthenic oil, rubber and EVA, stir for 4 hours, add antioxidant 1010, rosin resin and filler, stir for another 4 hours, and discharge the materials through the die head Coating, use PE film on both sides, compound into a double-sided adhesive tape with a thickness of 1mm and a width of 1.2M for...

Embodiment 2

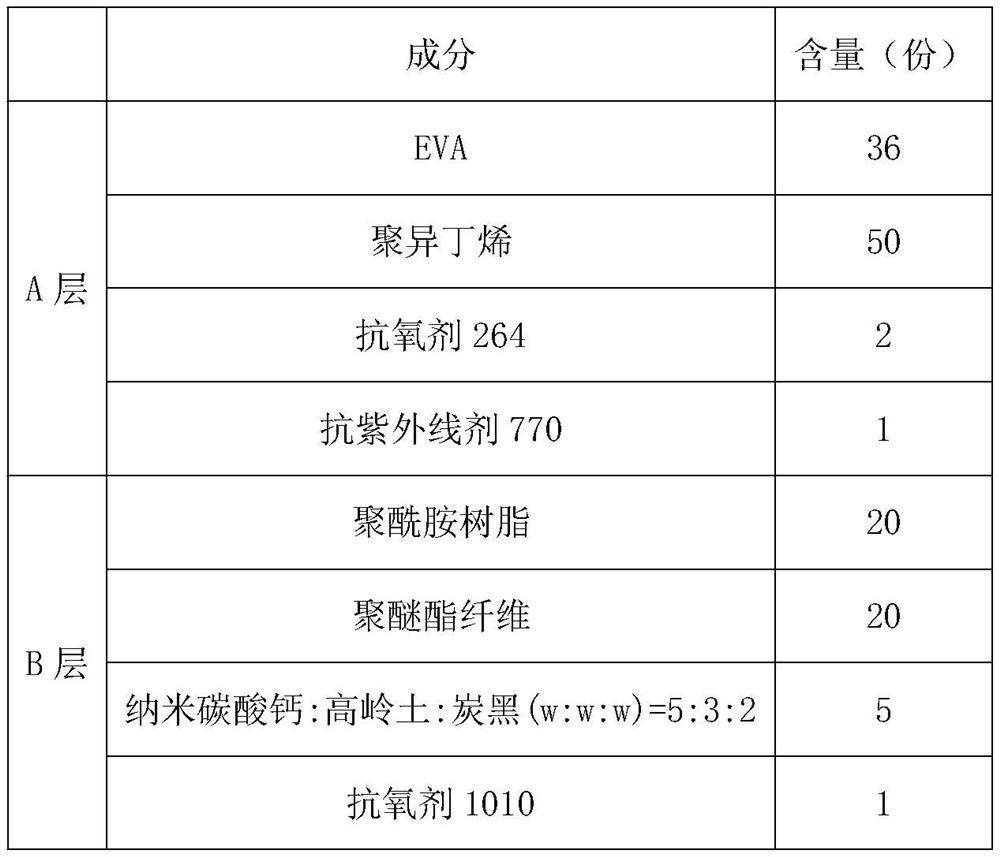

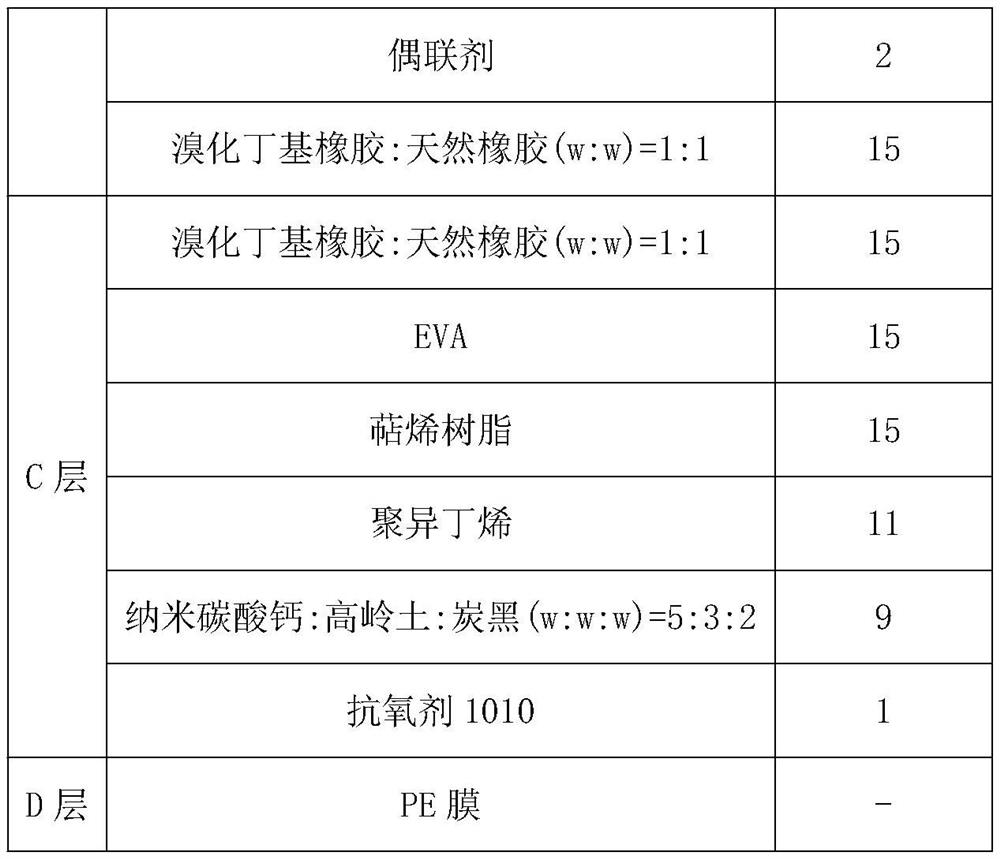

[0030] A tire self-repairing rubber strip of the present invention has a formula shown in Table 2 below.

[0031] Table 2 A formula of tire self-repairing rubber strip

[0032]

[0033]

[0034] A preparation method for a tire self-repairing rubber strip, comprising the steps of:

[0035] (1) Preparation of layer A: Add polyisobutylene, antioxidant 264, and anti-ultraviolet agent 770 to the reaction kettle, react at 240°C for 2 hours, then add EVA, stir for 4 hours, and then discharge the material, and then use a coating machine to make a thickness of 2mm Thickness, width of 1.2 meters of coils for use;

[0036] (2) Preparation of layer C: heat the reaction kettle to 240°C, put in polyisobutylene, rubber and EVA, stir for 4 hours, add antioxidant 1010, rosin resin and filler, stir for another 4 hours, discharge the materials through the die head for coating Cloth, with PE film on both sides, compounded into a double-sided adhesive tape with a thickness of 1mm and a wid...

Embodiment 3

[0040] A tire self-repairing rubber strip according to the present invention has a formula shown in Table 3 below.

[0041] Table 3 A formula of tire self-repairing rubber strip

[0042]

[0043] (1) Preparation of layer A: Add naphthenic oil, antioxidant 2246, and anti-ultraviolet agent 770 into the reaction kettle, react at 240°C for 2 hours, then add EVA, stir for 4 hours, and then discharge the material, and then use a coating machine to make a layer with a thickness of 2mm thick, 1.2m wide coils for use;

[0044](2) Preparation of layer C: Heat the reaction kettle to 240°C, put in naphthenic oil, rubber and EVA, stir for 4 hours, add antioxidant 1010, rosin resin and filler, stir for another 4 hours, and discharge the materials through the die head Coating, use PE film on both sides, compound into a double-sided adhesive tape with a thickness of 1mm and a width of 1.2M for use.

[0045] (3) Preparation of layer B: Mix polyamide resin, polyetherester fiber, filler, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com