Preparation method for producing baking-free bricks by cooperatively utilizing household garbage incineration slag and waste plastic particles

A domestic waste incineration and brick-free technology, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

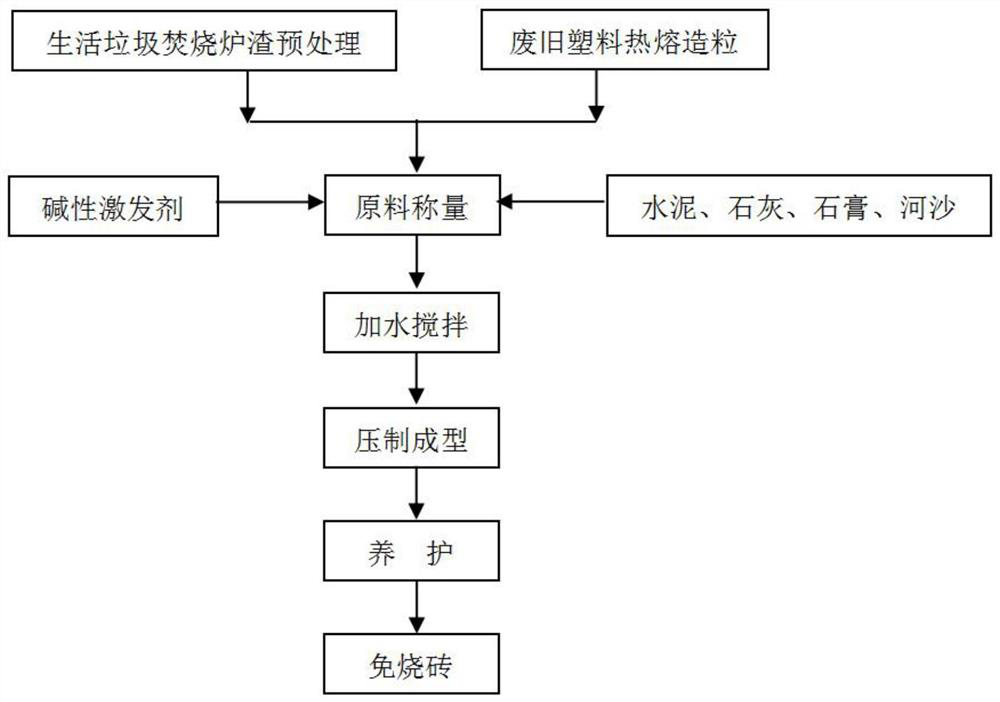

[0020] The invention provides a preparation method for synergistically producing non-burning bricks by utilizing domestic waste incineration slag and waste plastic particles, comprising the following steps:

[0021] 1) Domestic waste incinerator slag is used as recycled aggregate after pretreatment;

[0022] 2) Waste plastics are used as recycled aggregates after hot-melt granulation;

[0023] 3) mixing the domestic waste incineration slag regenerated aggregate and waste plastic granule regenerated aggregate generated in step 1) and step 2) into river sand, cement, lime, and gypsum as raw materials, and adding an alkali activator to obtain a mixture;

[0024] 4) Stirring and mixing the mixture prepared in step 3) with water to form an embryo body and curing to obtain unburned bricks; the mass ratio of the mixture to water is (80-85): (15-20); The moisture content of the unburned brick is less than 5.7%.

[0025] The domestic garbage incinerator slag of the present invention ...

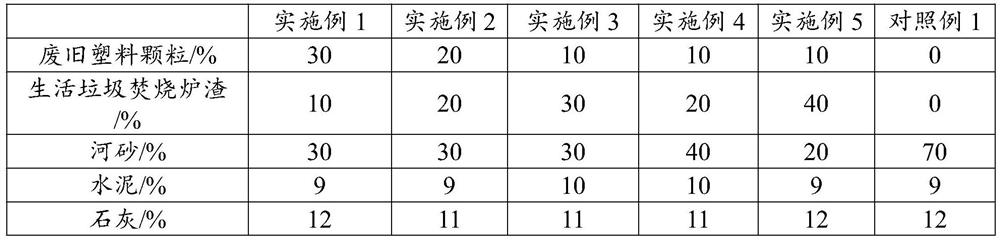

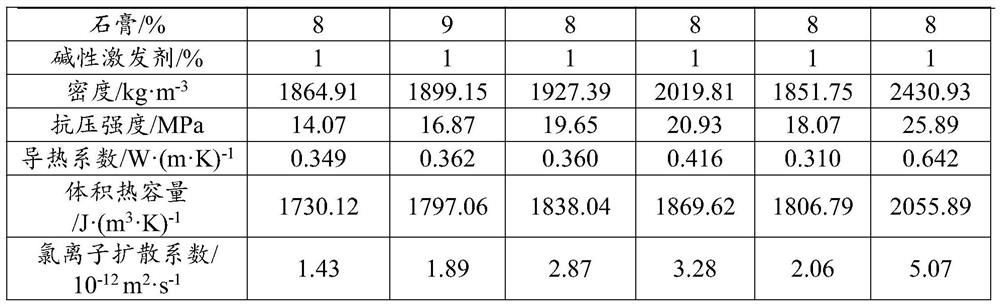

Embodiment 1

[0043] A preparation method for synergistically producing non-burning bricks by using domestic waste incineration slag and waste plastic particles, comprising the following steps:

[0044] In the first step, the pretreatment process of domestic waste incineration slag includes magnetic separation and sorting, crushing and screening, washing, and natural drying, and the particle size is less than 7.5mm;

[0045] The second step is hot-melt granulation of waste plastics, with a particle size of 2.5-3.5mm;

[0046] In the third step, the domestic waste incineration slag regenerated aggregate and waste plastic granule regenerated aggregate generated in the first and second steps are mixed with river sand, cement, lime, and gypsum as raw materials, and a certain activator is added. for 10:30:30:9:12:8:1;

[0047] The 4th step, the mixture that the 3rd step is made is mixed with water, and the mass ratio of described mixture and water is 80:20, is poured into mould, makes embryo bo...

Embodiment 2

[0050] A preparation method for synergistically producing non-burning bricks by using domestic waste incineration slag and waste plastic particles, comprising the following steps:

[0051] The first step, the pretreatment process of domestic waste incineration slag includes magnetic separation and separation, crushing and screening, deionized water washing, natural drying, and the particle size is less than 7.5mm;

[0052] The second step is hot-melt granulation of waste plastics, with a particle size of 2.5-3.5mm;

[0053] In the third step, the domestic waste incineration slag regenerated aggregate and waste plastic granule regenerated aggregate generated in the first and second steps are mixed with river sand, cement, lime, and gypsum as raw materials, and a certain activator is added. for 20:20:30:9:11:9:1;

[0054] The 4th step, the mixing material that the 3rd step is made is mixed with water, and the mass ratio of described mixing material and water is 85:15, is poured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com