New cutter suction boat and amphibious bottom mud treatment platform

A treatment platform and cutter suction vessel technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve high cost of foreign transportation, large amount of dehydration, secondary pollution Serious problems, to achieve the effect of avoiding repeated investment, saving land resources, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

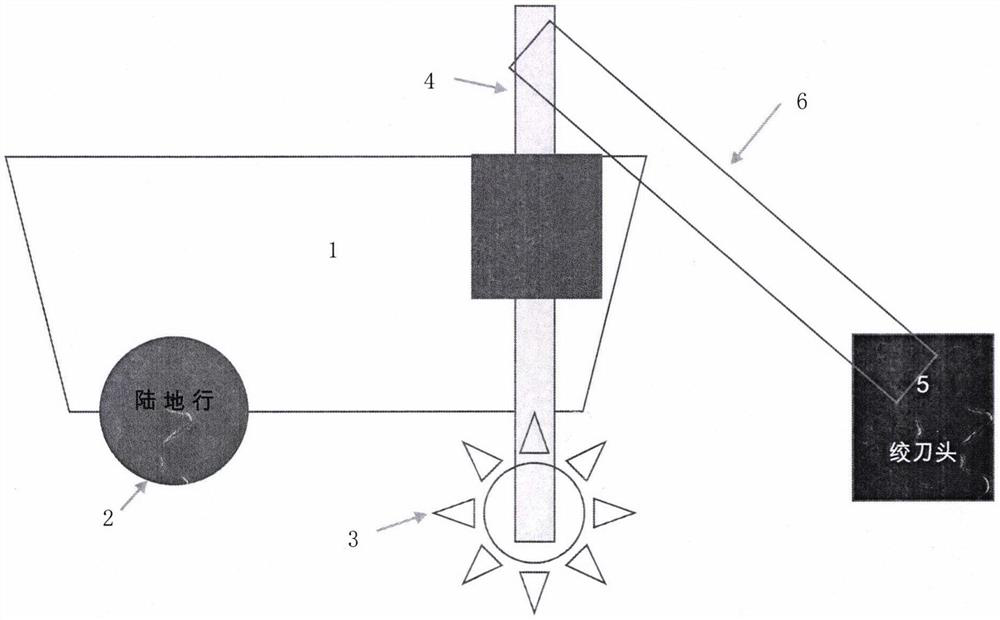

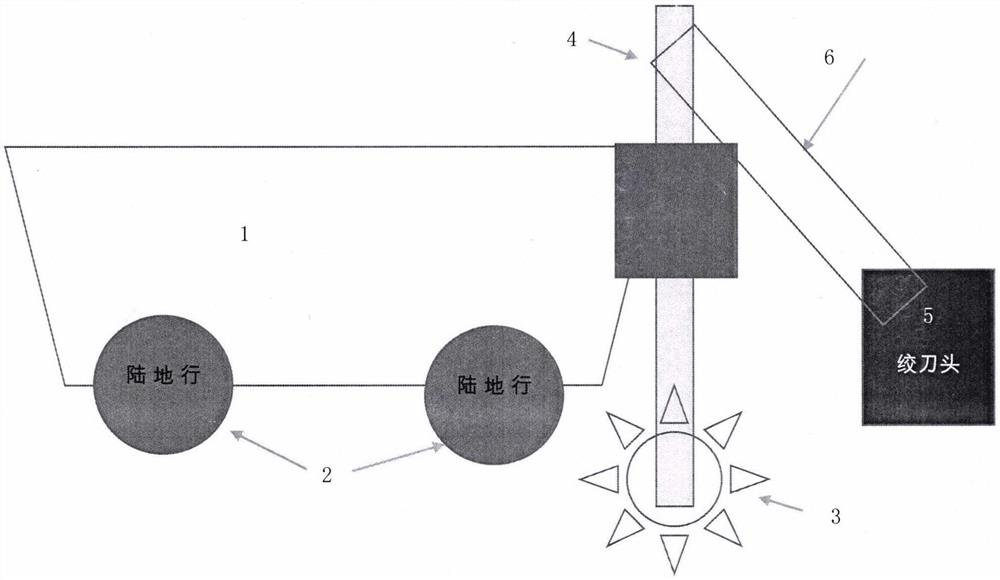

[0051] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described in detail with reference to the accompanying drawings, and the following will be described for the situation on the water surface; Suction boats, sediment storage sites, product collection boxes, etc. are omitted here.

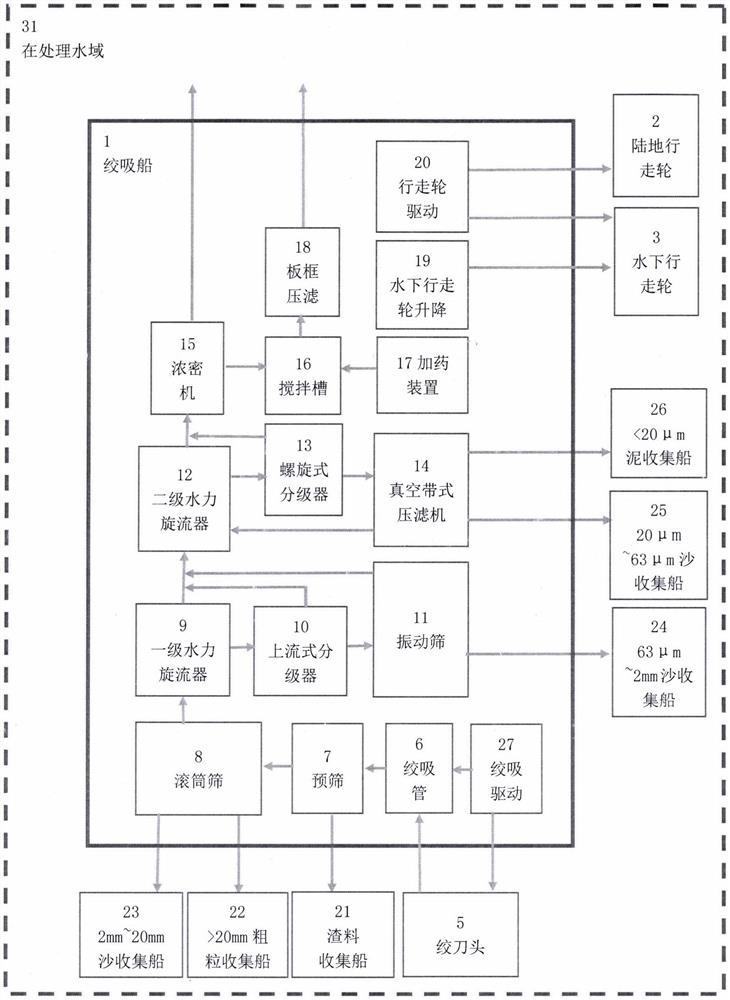

[0052] like image 3 As shown, the processing platform of the present invention mainly includes: pre-screening 7, trommel screen 8, primary hydrocyclone 9, upflow classifier 10, vibrating screen 11, secondary hydrocyclone 12, spiral classifier 13 , Vacuum belt filter press 14, thickener 15, stirring tank 16, dosing device 17, plate and frame filter press 18. There are also supporting slag collection ships 21, >20mm coarse particle collection ships 22, 2mm-20mm sand collection ships 23, 63μmm-2mm sand collection ships 24, 20μm-63μm sand collection ships 25, <20μm mud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com