Non-contact vibration damping linear vibration motor and implementation method thereof

A vibration damping, linear vibration technology, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as changing the spring stress distribution, damping characteristics affecting customer experience, etc., to maintain vibration damping unchanged, reduce magnetic field leakage, The effect of increasing space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

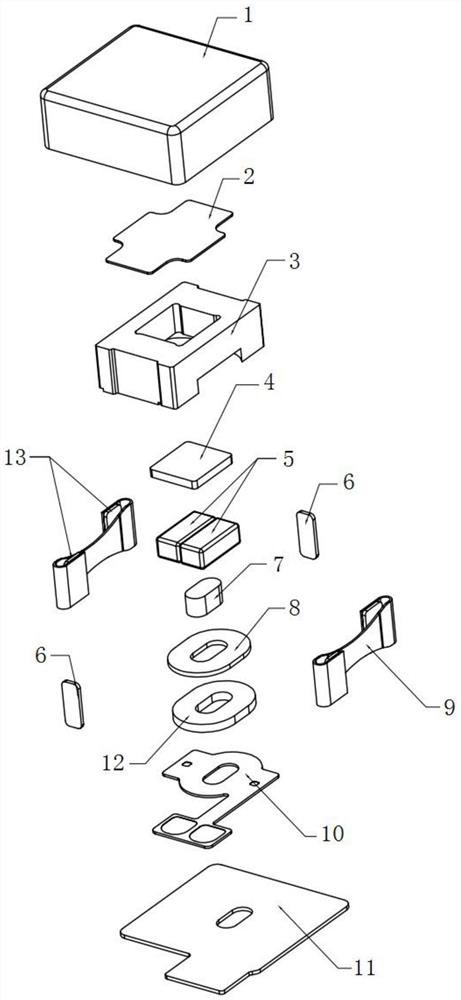

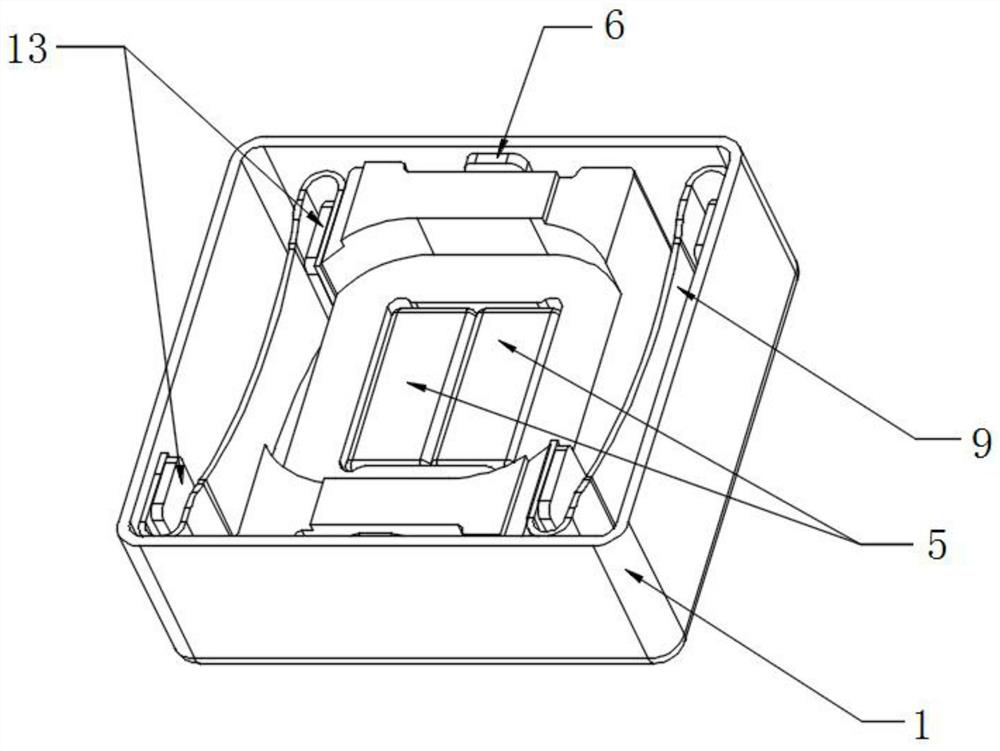

[0039] see Figure 1-8 , the present invention provides the following technical solutions: a linear vibration motor with non-contact vibration damping, including a casing 1 and a lower bracket 11, a stator assembly is arranged above the lower bracket 11, and a vibrator assembly is sleeved outside the stator assembly The outside of the vibrator assembly is covered with a casing 1, and the two sides of the vibrator assembly are connected to the casing 1 through a spring 9. The spring 9 is an S-shaped structure. The steel group, the top of the magnetic steel group is provided with a balance weight 4.

[0040] Further, the inside of the counterweight 3 is provided with a receiving groove 31 for accommodating the balance weight 4 and the magnetic steel group, and the upper part of the counterweight 3 is welded with the bracket 2 .

[0041] By adopting the above technical solution, the balance weight 4 is embedded in the interior of the accommodation groove 31 and welded to the bra...

Embodiment 2

[0059] see Figure 9 , The difference between this embodiment and Embodiment 1 is: further, the magnetic steel group includes three permanent magnets 5 arranged side by side.

[0060] Further, the implementation method of the non-contact vibration damping linear vibration motor according to the present invention includes the following steps:

[0061] (1), the casing 1 and the lower bracket 11 form a closed cavity for accommodating the internal stator assembly and vibrator assembly;

[0062] (2), the counterweight 3, the balance weight 4 and the magnetic steel group constitute the vibrator assembly, and the magnetic steel group provides a magnetic field for the motor drive;

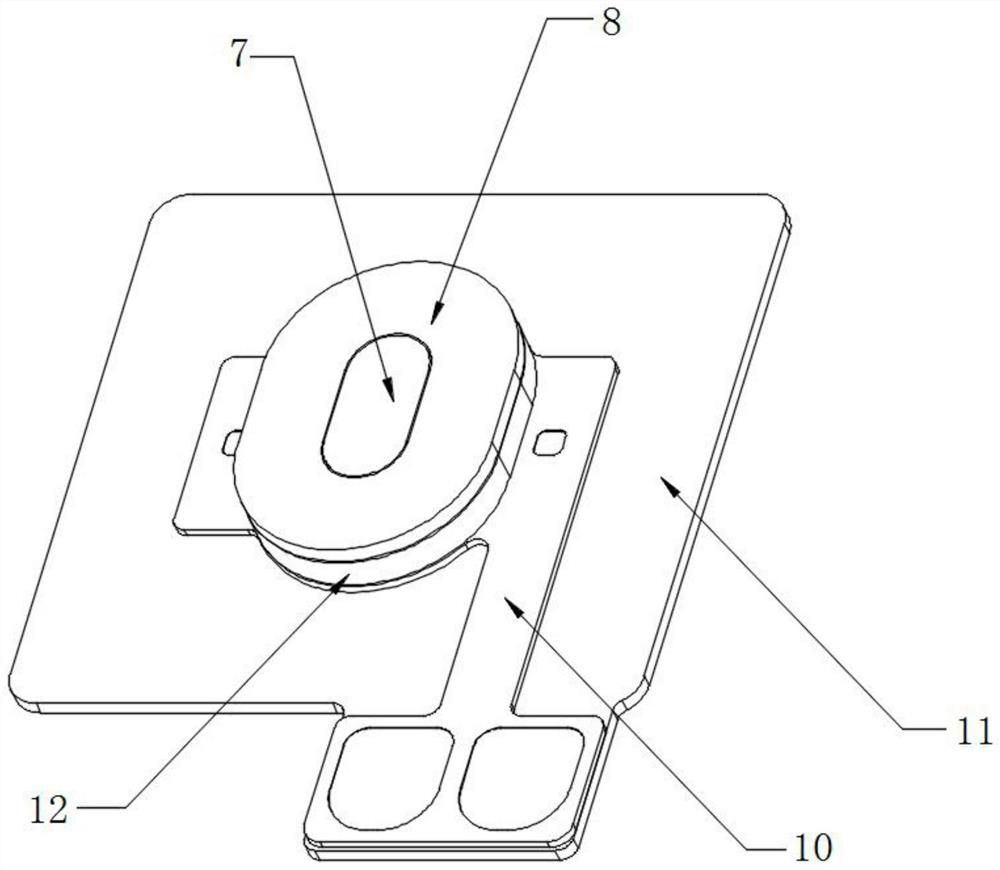

[0063] (3), the pole core 7, the loss sheet 8, the coil 12 and the FPC10 form a stator assembly, and the coil 12 and the FPC10 form a circuit, which generates an electric field when electrified, and the electric field interacts with the magnetic field to drive the motor to vibrate;

[0064] (4), the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com