Injection unit for tray, three-dimensional injection tray with large liquid holdup and gas-liquid mass transfer method thereof

A jet plate and liquid holdup technology, which is applied to the jet unit for trays, the three-dimensional jet tray with large liquid holdup and its gas-liquid mass transfer field, can solve problems such as large resistance drop, achieve small resistance drop and shorten the process , the effect of reducing the resistance drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

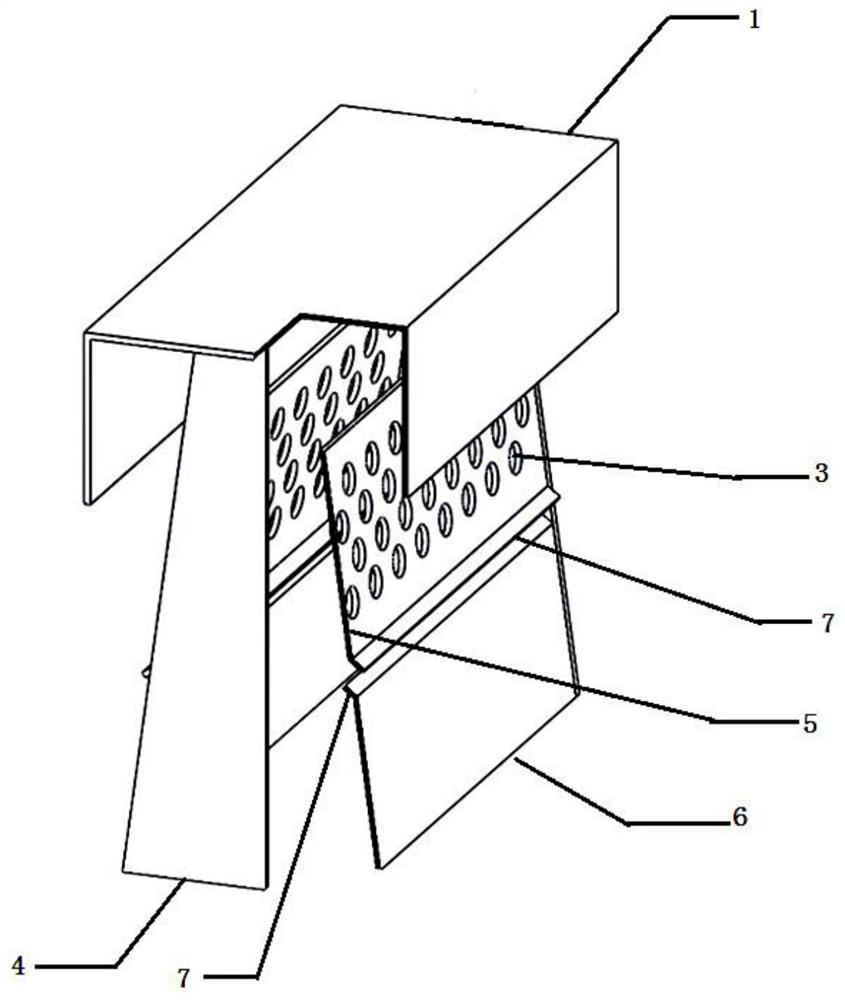

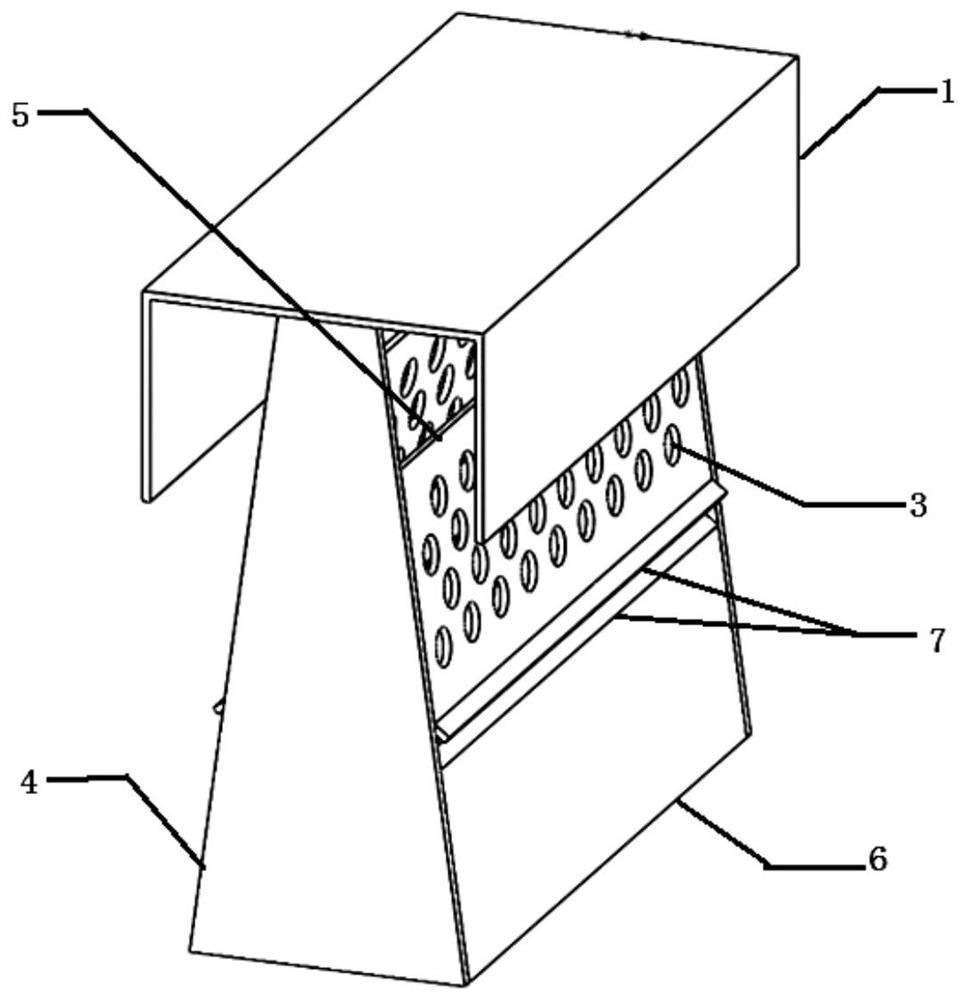

[0032] A spraying unit for a tray, comprising a spray hood and a gas-liquid separation plate 1 installed on the top of the spray hood, the middle part of the lift-up spray plate 5 of the spray hood forms a gap 2 for liquid to enter the spray hood, Spray holes 3 are provided on the top of the lift jet plate 5 of the spray hood, and spray channels are formed between the lift jet plate and the gas-liquid separation plate 1 .

[0033] The spray cover can be a cylindrical structure formed integrally, or it can be surrounded by two opposite lift jet plates and two opposite end plates 4 . The cross-sectional area of the spray hood can be the same from bottom to top, or it can be gradually reduced, preferably in a gradually shrinking arrangement. The cross-section of the spray hood is circular, square or rectangular, preferably rectangular.

[0034] The air-lifting injection plate can be an integrally formed plate, the slit 2 is opened in the middle, and the injection hole 3 is open...

Embodiment 2

[0038] The three-dimensional injection tray with large liquid holding capacity includes a tray body 8, and the tray body 8 is provided with regularly arranged plate holes, and each plate hole is equipped with a spray unit as described in Embodiment 1. The bottom of the gas lift plate 6 is welded on the upper surface of the tray body 8 , and the two sides of the injection plate 5 and the gas lift plate 6 are respectively welded to the edge of the end plate 4 . Compared with the structure in CN1736528A, this invention has only one structure, which is directly welded to the tower plate, without gas riser, and has a simpler structure, more convenient processing, and saves consumables.

[0039] As preferably, the included angle between the lifter plate 6 and the tray body 8 is 5-150°, the plate holes are rectangular, trapezoidal or circular, and the arrangement number of the plate holes is 1-25, and the trays The opening ratio is 1-25%, the air lift plate 6 is rectangular or trapez...

Embodiment 21

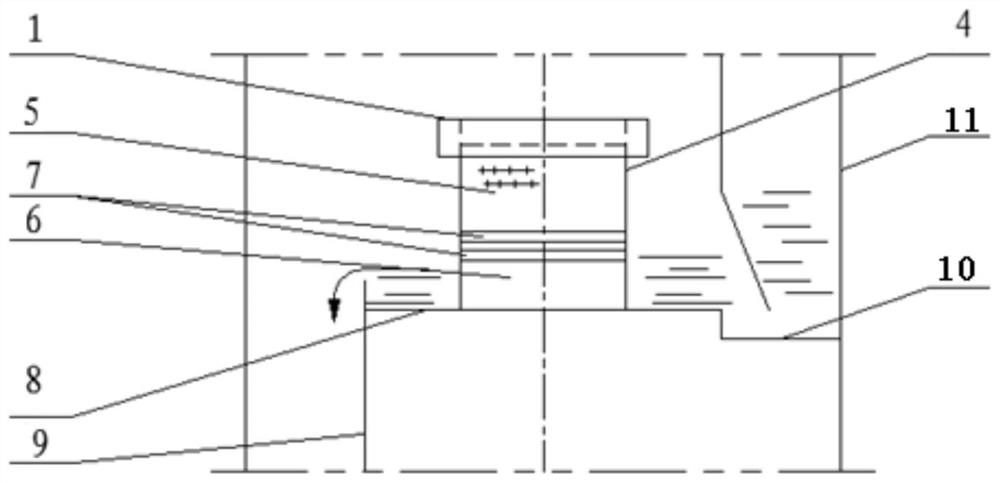

[0043] The tower body 11 is provided with a three-dimensional injection tray structure with a large liquid holding capacity, and its parameters are as follows:

[0044] Downcomer plate area / tower cross-sectional area = 14.2%, tray opening ratio 8.87% (4 30x210 rectangular holes), plate spacing 500mm, weir height 150mm, downcomer plate bottom gap height 50mm.

[0045] In this embodiment, the spray hood is surrounded by two opposite lift jet plates and two opposite end plates. The cross-sectional area of the spray cover gradually decreases from bottom to top, and the cross-section of the spray cover is rectangular.

[0046] The air-lifting injection plate is composed of an injection plate and an air-lifting plate arranged up and down, the gap is formed between the injection plate and the air-lifting plate, and the injection holes are opened on the injection plate.

[0047] An inclined liquid guide plate is fixed on the bottom edge of the spray plate and the top edge of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com