A biological filter tower for organic waste gas

A technology of organic waste gas and filter tower, which can be used in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., and can solve problems such as poor organic waste gas filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

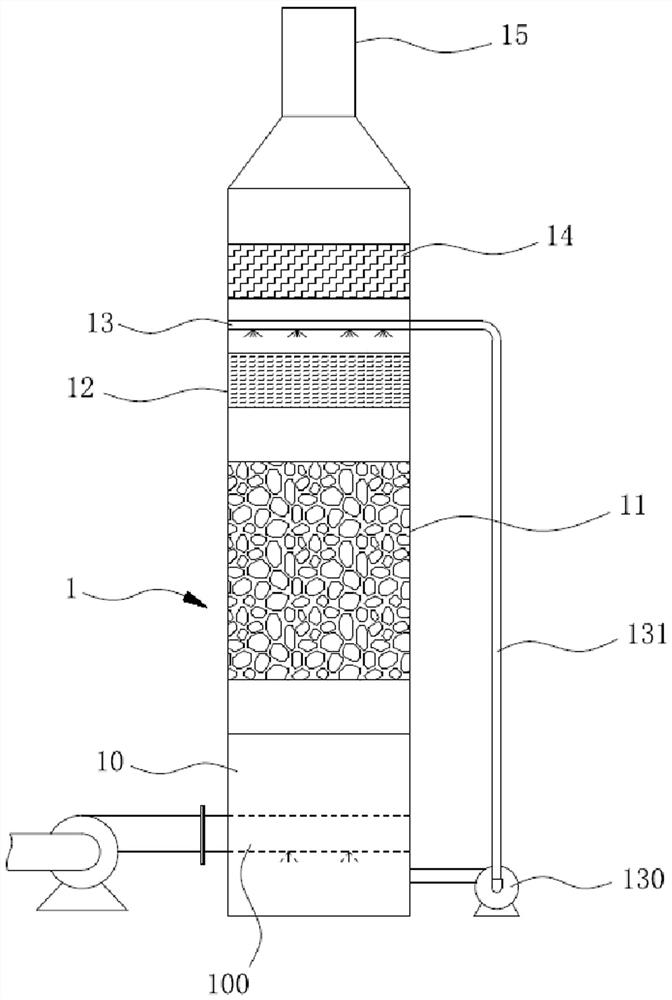

[0032] Such as figure 1 As shown, the organic waste gas biological filtration tower includes a tower body 1, and the tower body 1 is sequentially provided with a water storage layer 10 and a biodegradation layer 11 from bottom to top. The top of the tower body 1 is provided with an exhaust port 15. The water outlet is connected to the water source, and the outlet of the water storage layer 10 is connected to the water treatment system. The water storage layer 10 is built with an air distribution device 100, and the air distribution device 100 is preferably an aeration plate, and the air inlet of the air distribution device 100 passes through a pipe equipped with a fan Connect the exhaust gas source, the tower body 1 is provided with a spray assembly 13, the spray assembly 13 is located above the biodegradable layer 11, the spray assembly 13 includes a bracket installed in the tower body 1, and an installation pipe is installed on the bracket. The pipe is provided with several ...

Embodiment 2

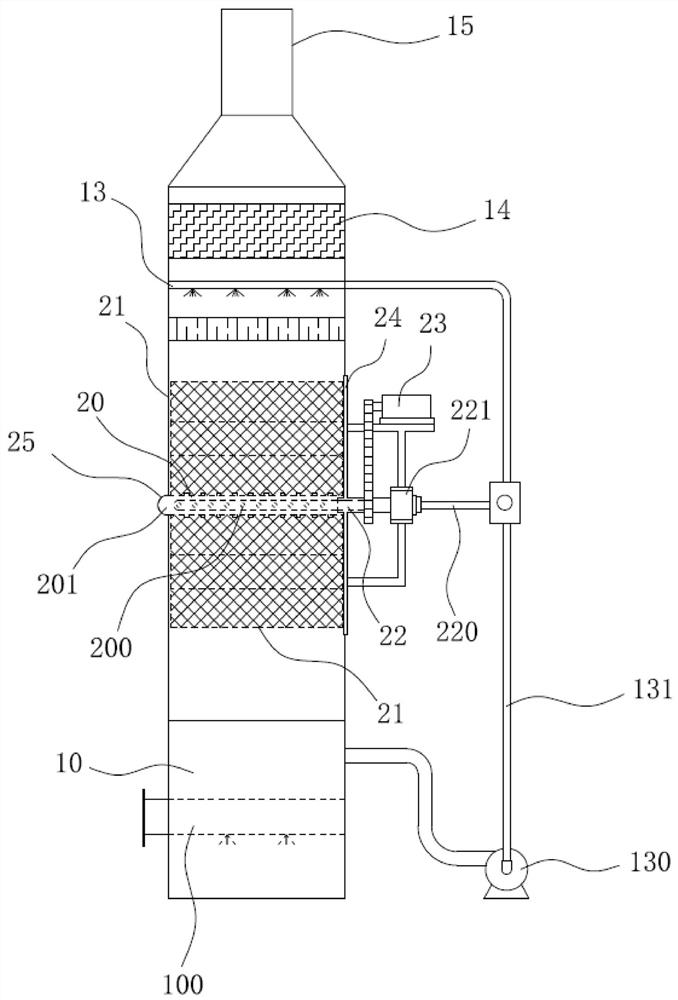

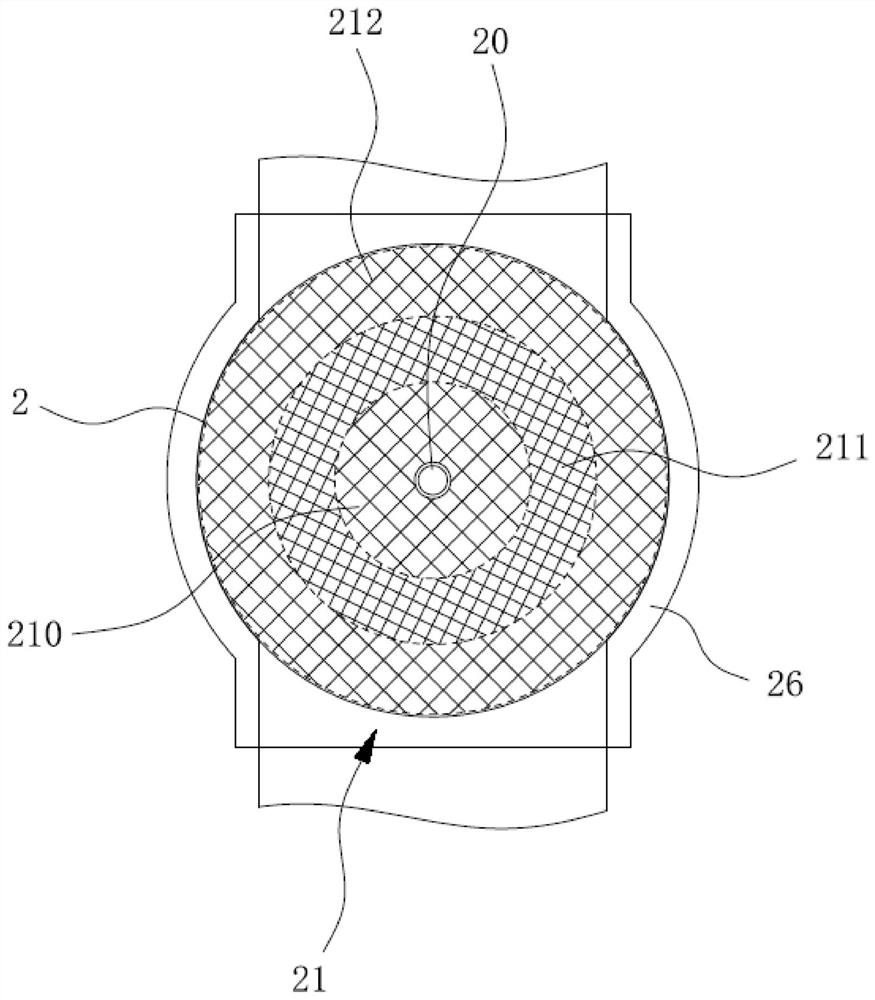

[0038] The difference between the present embodiment and the first embodiment lies in the structure of the biodegradable layer 11, such as figure 2 and image 3 Commonly shown, the biodegradable layer 11 includes a cylinder 2 arranged horizontally. The cylinder 2 is an integrally formed part of the tower body 1. A first hollow shaft 20 is coaxially installed in the cylinder 2. On the first hollow shaft 20, a There are several through holes 200, the several through holes 200 are arranged at intervals along the axial direction of the first hollow shaft 20, and are arranged in a circle around the axis of the first hollow shaft 20, and the first hollow shaft 20 is connected with The mesh cylinder 21 of degradable filler, the mesh cylinder 21 clearance fits in the cylinder 2, the outer wall of the mesh cylinder 21 and the inner wall of the cylinder 2 are provided with a nylon sleeve, and one end of the first hollow shaft 20 is rotatably connected to the cylinder 2, The other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com