Special device for laser cutting of diamond material

A laser cutting and special device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of diamond weight loss, economic value loss, large size, etc., to improve cutting quality and efficiency, and ensure processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

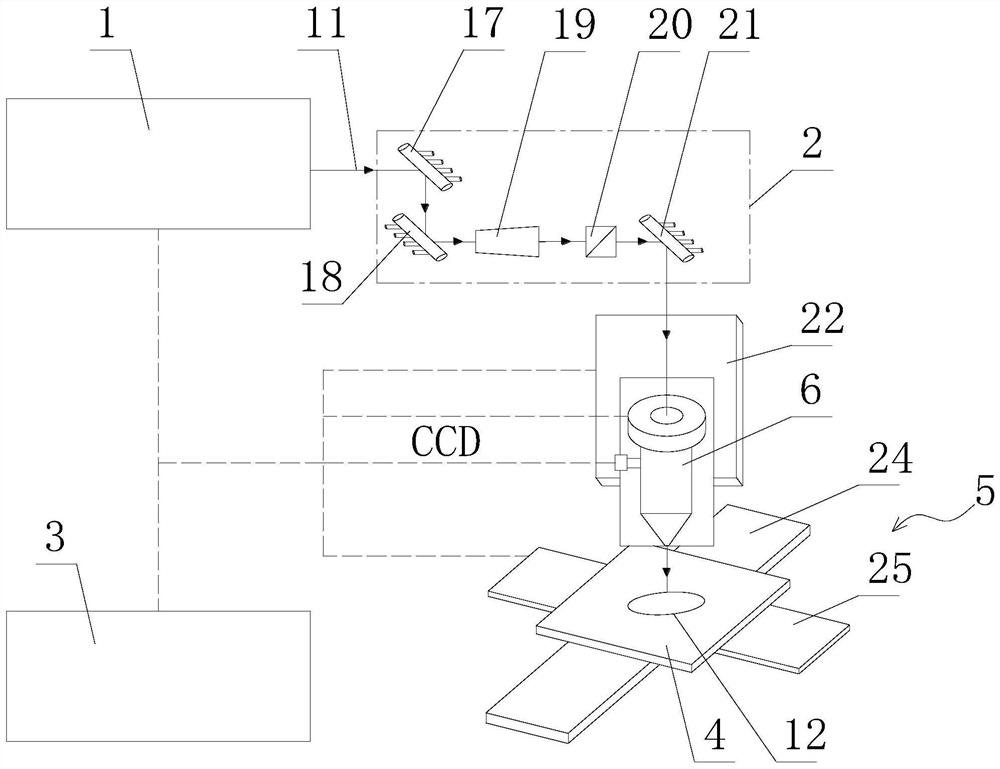

[0038] refer to Figure 1-2 , the rotating motor 10 is a hollow shaft motor, the wave plate 9 is connected to the rotating shaft of the rotating motor 10, the structure arranged coaxially between the rotating motor 10 and the wave plate 9, the rotating motor 10 is installed on the frame 7, and the laser 11 passes through the external optical path in turn The module 2 and the wave plate 9 irradiate the workpiece 4 .

Embodiment 2

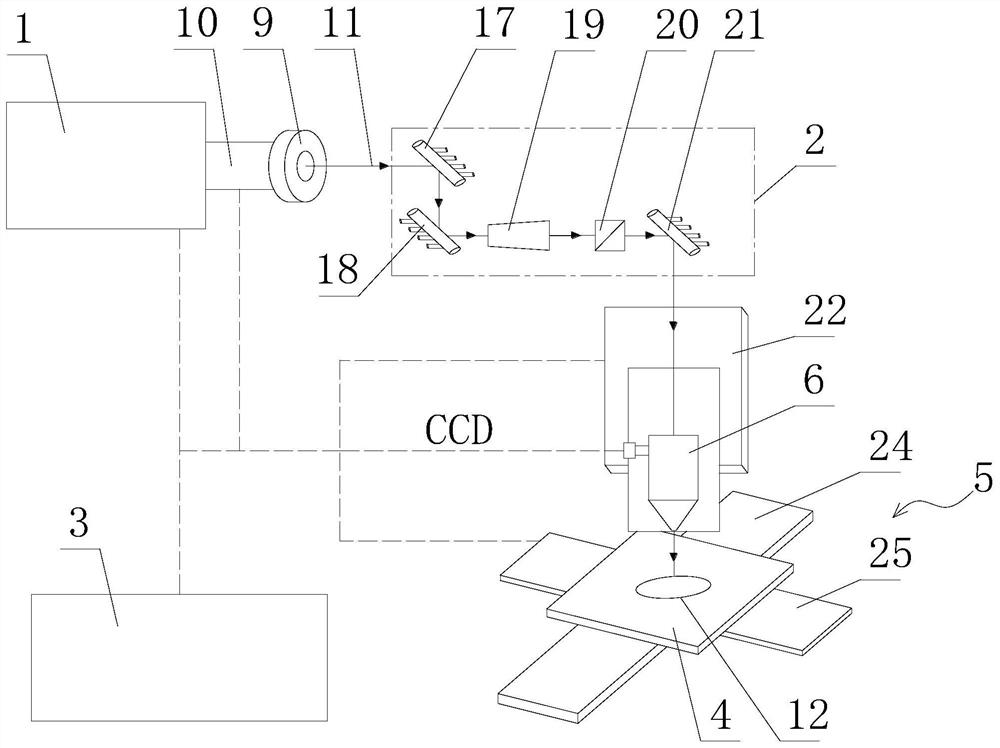

[0040] refer to image 3 , the rotating motor 10 is a hollow-shaft motor, the wave plate 9 is connected to the rotating shaft of the rotating motor 10, the structure arranged coaxially between the rotating motor 10 and the wave plate 9, the wave plate 9 is installed on the laser output end of the laser 1, and the laser 11 is in turn The workpiece 4 is irradiated through the wave plate 9 and the external optical path module 2 .

Embodiment 3

[0042] refer to Figure 4 , the rotating motor 10 is a hollow-shaft motor, the wave plate 9 is connected to the rotating shaft of the rotating motor 10, the structure arranged coaxially between the rotating motor 10 and the wave plate 9, and the wave plate 9 is installed on the incident end or the outgoing end of the external optical path module 2 , the laser 11 irradiates the workpiece 4 through the wave plate 9 and the external optical path module 2 in sequence, or irradiates the workpiece 4 through the external optical path module 2 and the wave plate 9 in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com