Composition for glass, aluminosilicate glass, as well as preparation method and application of the aluminosilicate glass

An aluminosilicate glass and composition technology, which is applied in the field of glass manufacturing, can solve the problems of difficult glass melting and forming, large plate forming, and easy bending, and achieves the effect of ensuring high glass yield and optimizing glass thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] There is no special requirement for the preparation method of the above-mentioned aluminosilicate glass, for example, it can be: fully mix the various raw materials of the above-mentioned composition for glass, and keep it warm at 1630-1680°C for 7-24 hours in a platinum-rhodium crucible, during which Stir with a platinum rod to remove air bubbles and clarify and homogenize the glass liquid. Then, pour the melted molten glass onto a stainless steel mold to form it, anneal at 800°C and then perform mechanical processing to obtain aluminosilicate glass.

[0056] There is no particular limitation on the mechanical processing, which may be various common mechanical processing methods in the art, for example, cutting, grinding, polishing, etc. may be performed on the product obtained by the annealing treatment.

[0057] In the third aspect, the present invention provides the aluminosilicate glass prepared by the above method.

[0058] For the thickness of the above-mentione...

Embodiment

[0071] Specific embodiments of the present invention will be described in detail below. It should be understood that all the materials described herein according to the present invention can be obtained commercially, and the methods used are conventional methods in the art unless otherwise specified. The embodiments are only used to illustrate and explain the present invention, not to limit the present invention.

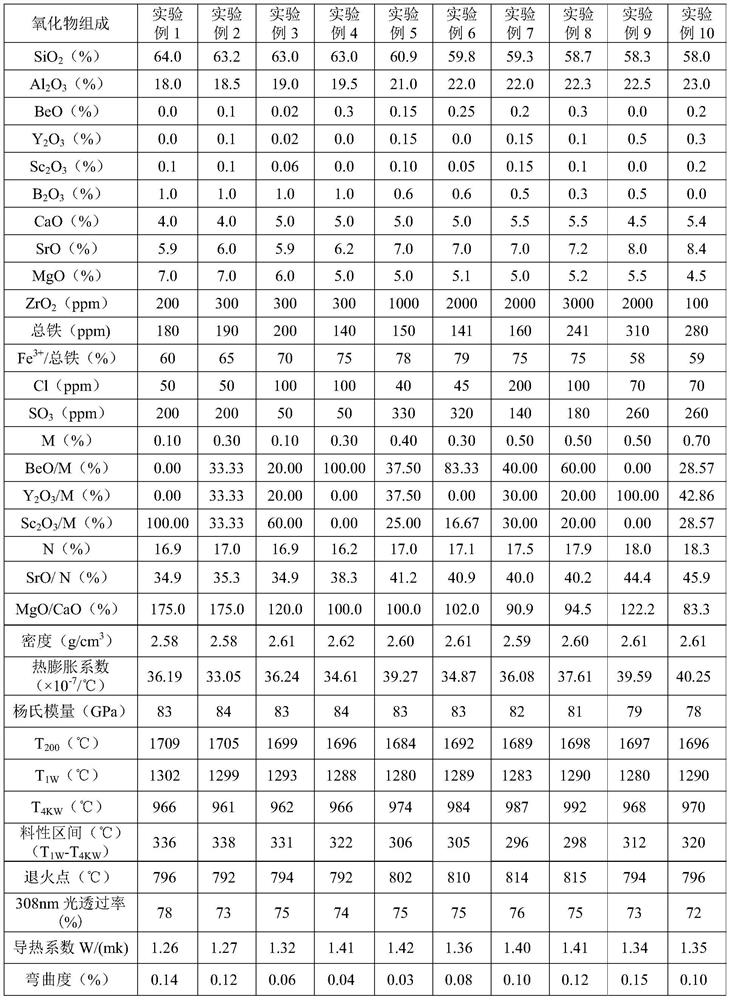

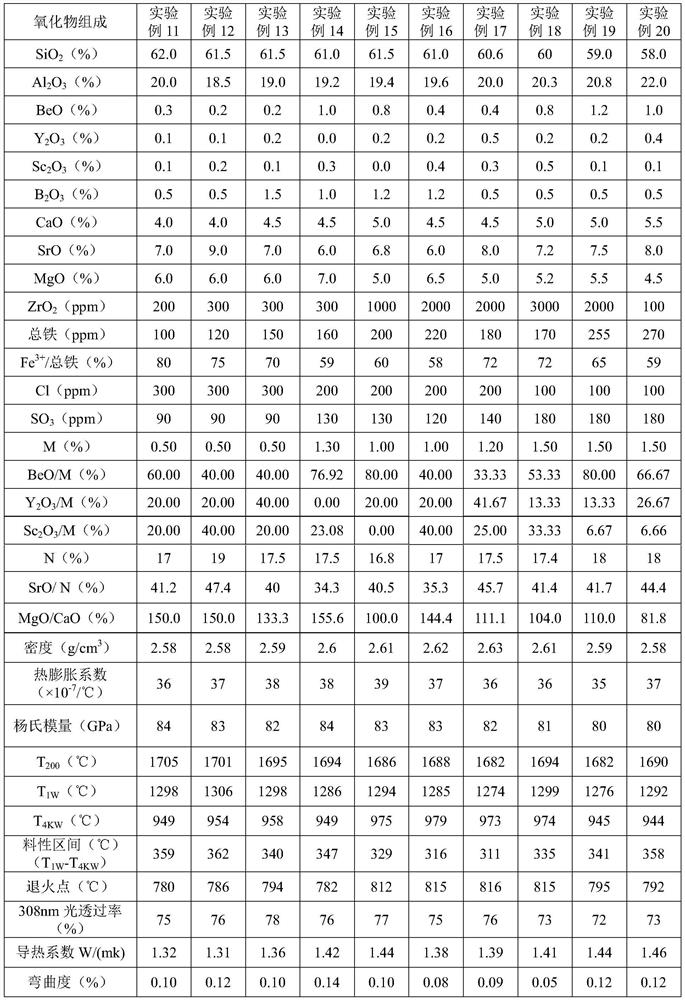

[0072] According to the present invention, the compositions of the glass compositions and the measurement results in the examples and comparative examples are shown in Tables 1-3. In addition, the glasses in Examples and Comparative Examples were prepared according to the following methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com