Oil field automatic profile modification operation device and application method

An operating device and automatic technology, applied in chemical instruments and methods, earthwork drilling, transportation and packaging, etc., can solve the problems of non-standard dosing methods, high operating costs, and high labor intensity, so as to reduce labor intensity and Safety risk, improved accuracy and timeliness, effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

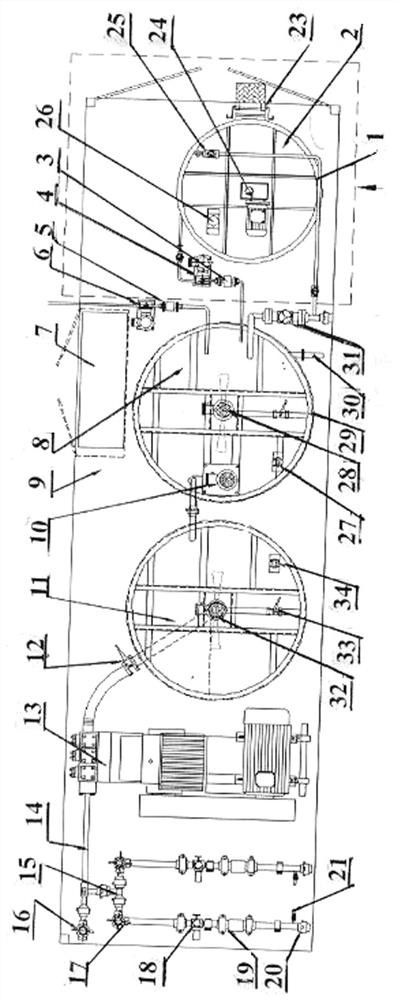

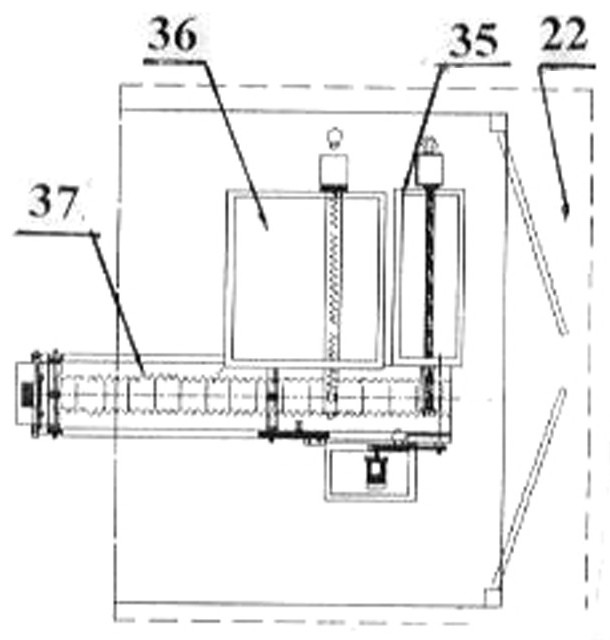

[0019] Embodiment 1. The present invention includes a single-phase gel dosing skid 1, a single-phase gel dilution tank 2, an artificial electromagnetic flowmeter 3, a first diaphragm metering pump 4, a micro flow meter 5, and a second diaphragm metering pump 6 , electrical control device 7, dispensing mixing tank 8, main skid 9, vertical mud pump 10, profile control tank 11, butterfly valve 12, high-pressure plunger pump 13, high-pressure pipe 14, high-pressure water separator 15, emptying needle valve 16. Needle valve 17, high-pressure flow automatic controller 18, high-pressure check valve 19, union 20, pressure relief valve 21, solid dosing skid 22, dosing flip support frame 23, dilution filling agitator 24, water distribution needle Valve 25, dilution irrigation ultrasonic level gauge 26, mixing tank ultrasonic level gauge 27, mixing tank agitator 28, mixing tank sewage pipe 29, overflow pipe 30, water distribution electric valve 31, mud pump agitator 32, mud pump sewage P...

Embodiment 2

[0020] Embodiment 2, the inlet pipeline of the second diaphragm metering pump 6 is connected with the barreled liquid medicament with a plastic pipe, and extends into the bottom of the plastic barrel, and the outlet pipeline of the second diaphragm metering pump 6 is a plastic pipeline and a micro flowmeter 5 The inlet of the micro-flowmeter 5 is connected with a special joint, and the outlet of the micro flowmeter 5 is connected with a plastic pipeline to extend into the top tank of the dispensing mixing tank 8; the legs of the dispensing mixing tank 8 are connected with the top surface of the skid seat 9 with bolts; Described agitation tank ultrasonic level gauge 27 is connected with the top of dispensing agitation tank 8 with support frame; The bottom of the dispensing mixing tank 8 is connected with a flange; the overflow pipe 30 is welded to the upper tank wall of one side of the dispensing mixing tank 8 with an elbow; the water distribution electric valve 31 is connected ...

Embodiment 3

[0021] Embodiment 3, the upper part of the main skid 9 is equipped with a single-phase gel dosing skid 1, an electrical control device 7, a mixing tank 8 for dispensing, a profile control tank 11, and a high-pressure plunger pump 13, and the main skid 9 and the base are used Bolted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com