Pipeline preparation device based on building electrical firefighting

A technology for building electrical and preparation equipment, applied in the field of pipelines, which can solve the problems of reducing the working efficiency of pipelines, time-consuming and labor-intensive handling of pipelines, and lack of coating mechanisms, etc., to achieve the effects of optimizing the handling process, reducing labor intensity, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

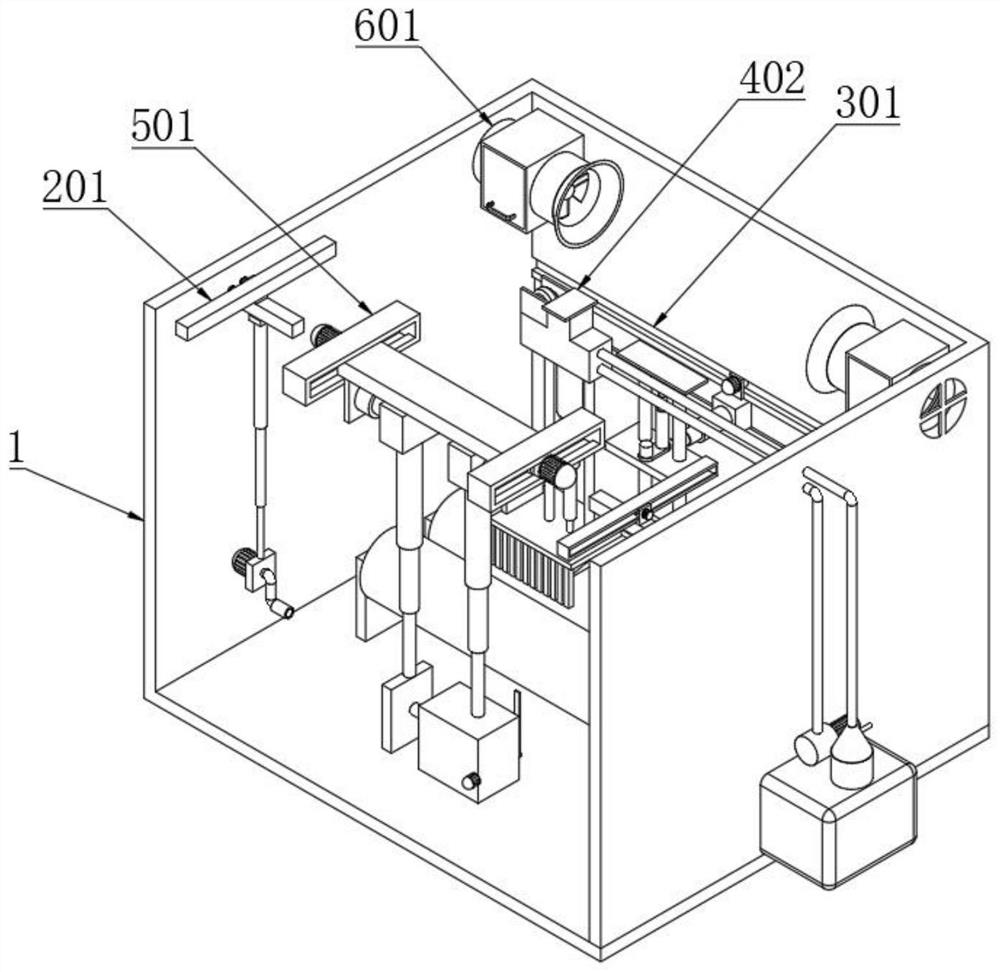

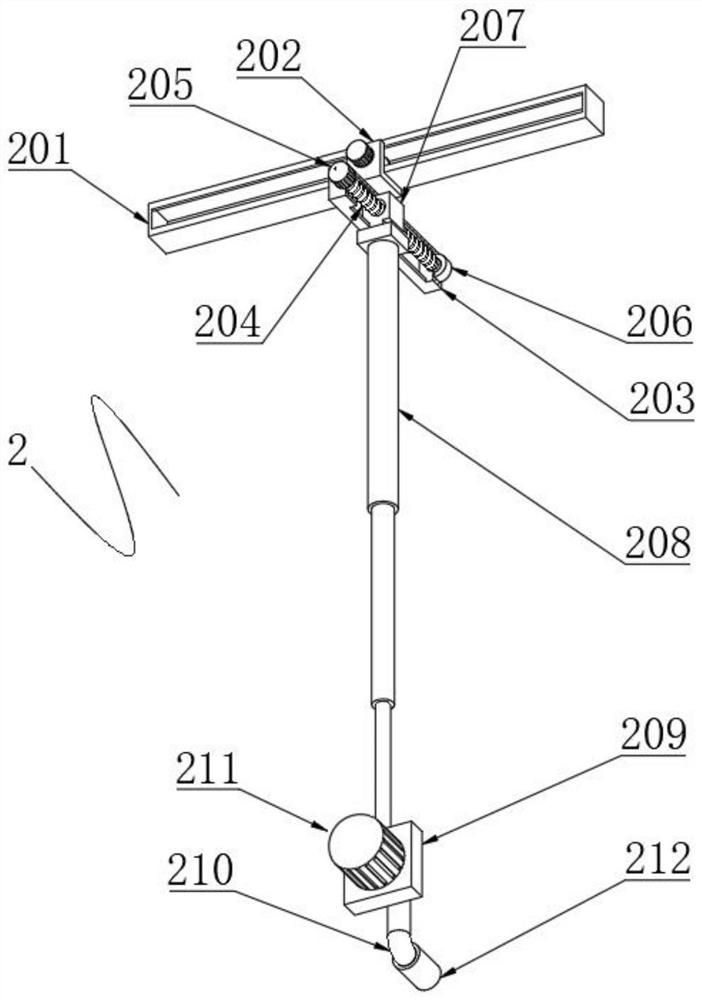

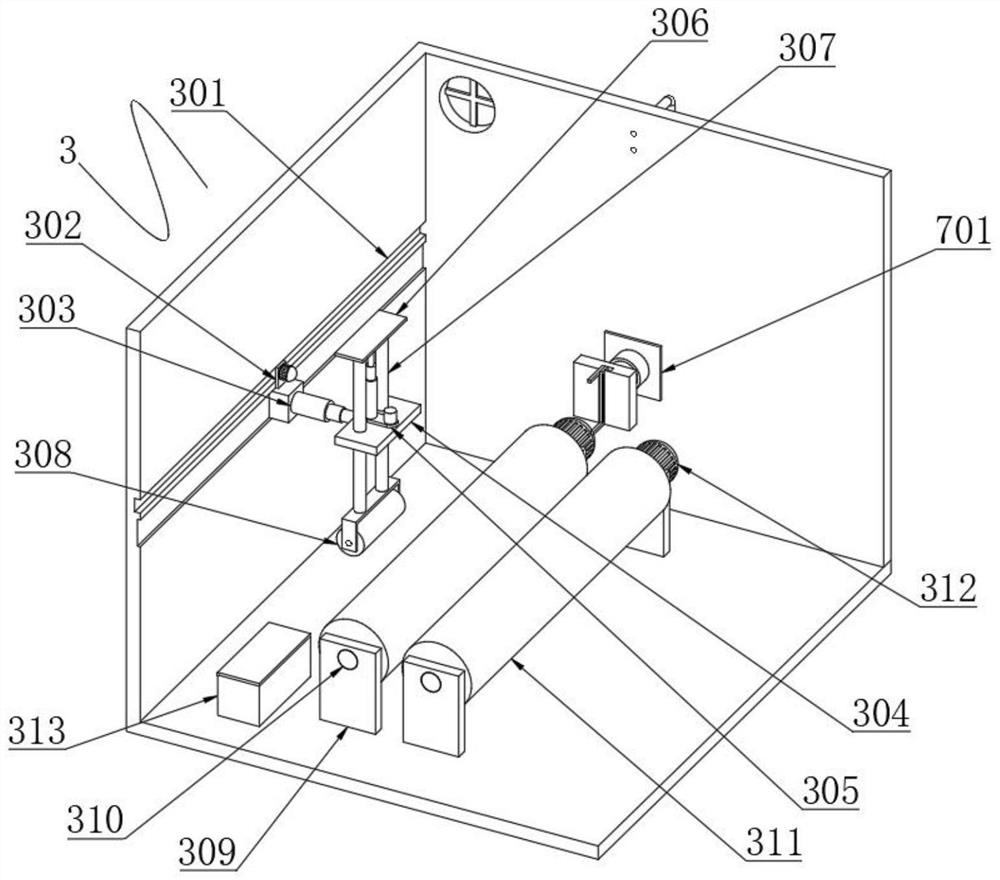

[0050] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a pipeline preparation device based on building electrical fire protection, including a fixed frame 1, a lifting door 8 is installed on one side of the fixed frame 1, which is convenient for the staff to carry the pipeline, and the inside of the fixed frame 1 A feeding mechanism 2 is provided, and the feeding mechanism 2 includes a sliding rod 201, a sliding plate 202, a connecting rod 203, a threaded rod 204, a threaded motor 205, a turntable 206, a sliding block 207, a lifting hydraulic rod 208, a connecting plate 209, and an S-type Rotating shaft 210, rotating shaft motor 211 and anti-slip sleeve 212;

[0051] A sliding rod 201 is installed symmetrically on the top of the inner side of the fixed frame 1, and a sliding plate 202 is slidably connected to the inside of the sliding rod 201. A connecting rod 203 is installed on the bottom end of the sliding plate 202, and a threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com