Novel high-temperature precooler for aircraft environmental control system

A technology of environmental control system and precooler, which is applied to aircraft parts, heat exchanger shells, indirect heat exchangers, etc., can solve the problems affecting the functional performance, reliability and durability of the aircraft environmental control system, and the safety of the precooler and reliability impact, pre-cooler leakage and other issues, to achieve the effect of compact structure, light weight, and slow decay of high temperature resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment, the invention of this structure will be further described, but should not be interpreted as that the scope of the subject matter of the invention of structure is limited to the following embodiments, without departing from the above-mentioned technical idea of the present invention, any according to Various modifications, substitutions and alterations made by ordinary technical knowledge and conventional means in the field are included within the scope of the present invention.

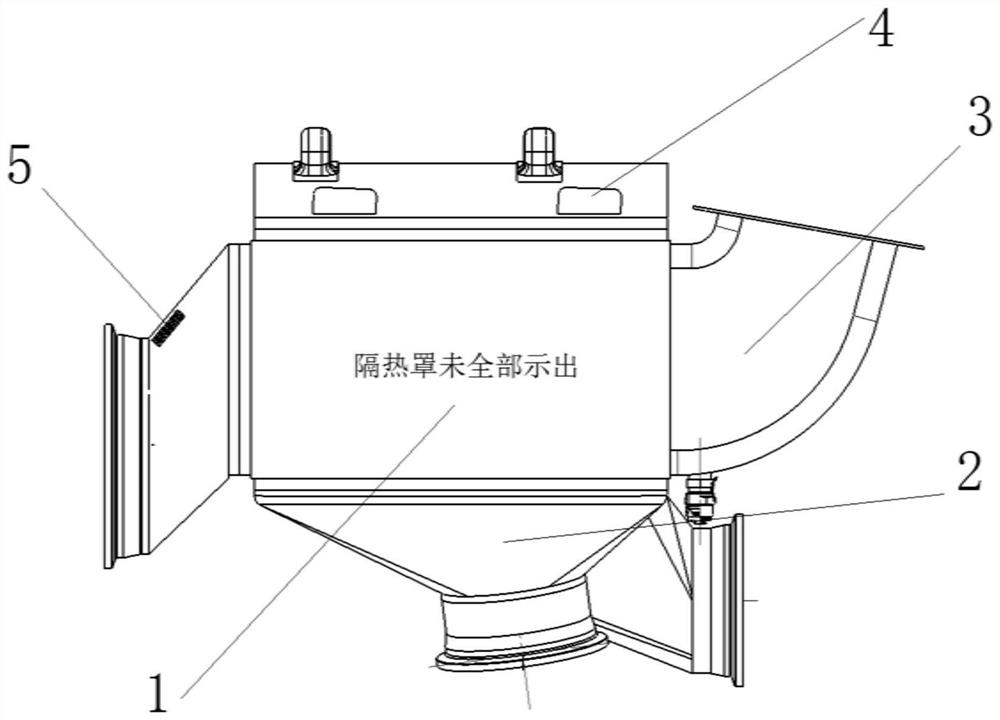

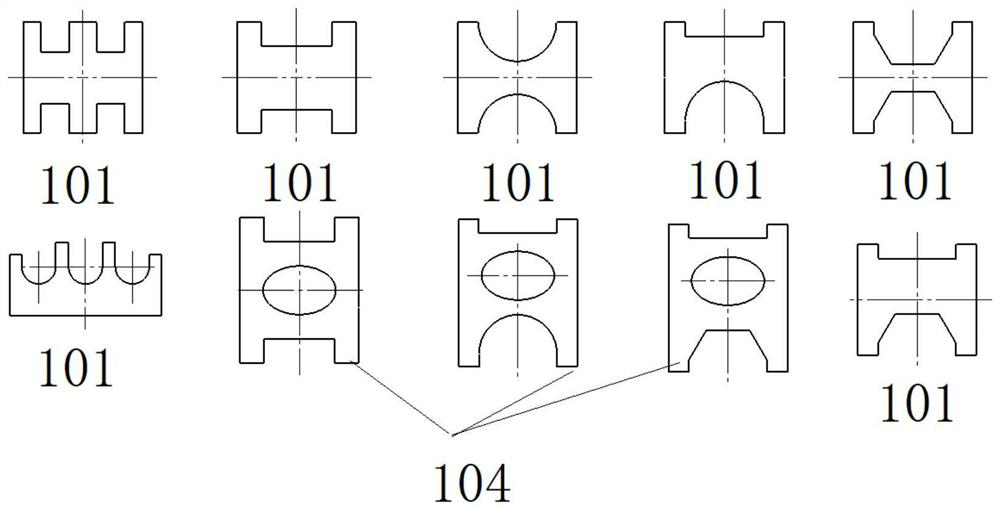

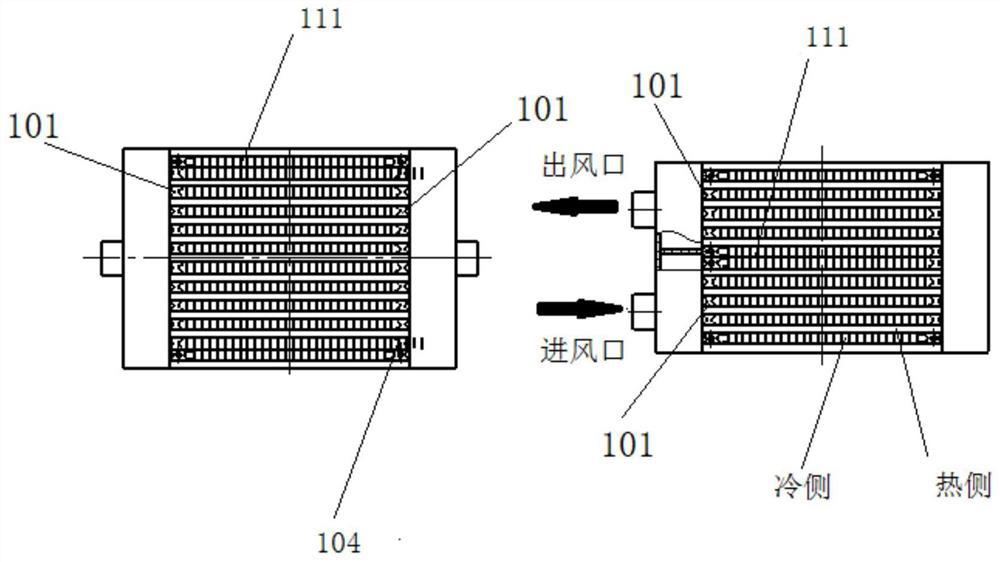

[0043] Such as Figure 1 to Figure 9As shown, it is a new type of high-temperature precooler for aircraft environmental control system according to the present invention, which includes a core assembly 1, a hot side inlet and outlet hood assembly 2, a cold side inlet and outlet hood assembly 3 and a mounting seat Component 4, heat shield component 5 and bellows type thermal expansion compensation joint 6; precooler core c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com