Intelligent zero-discharge drainage method and drainage sedimentation tank applying same

A zero-emission, sedimentation tank technology, applied in separation methods, sedimentation separation, chemical instruments and methods, etc., can solve the problems of large area of the amplitude flow sedimentation tank, intermittent water inflow, large instantaneous water inflow, etc. The effect of particle settling distance, reducing drop height, and slowing water velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

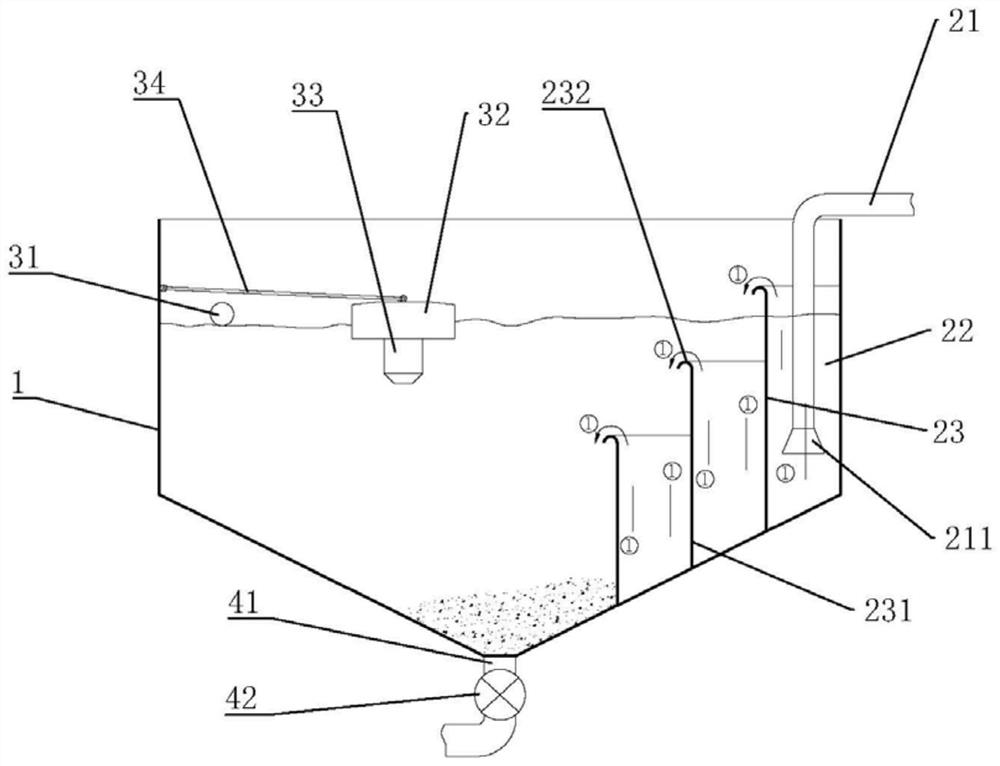

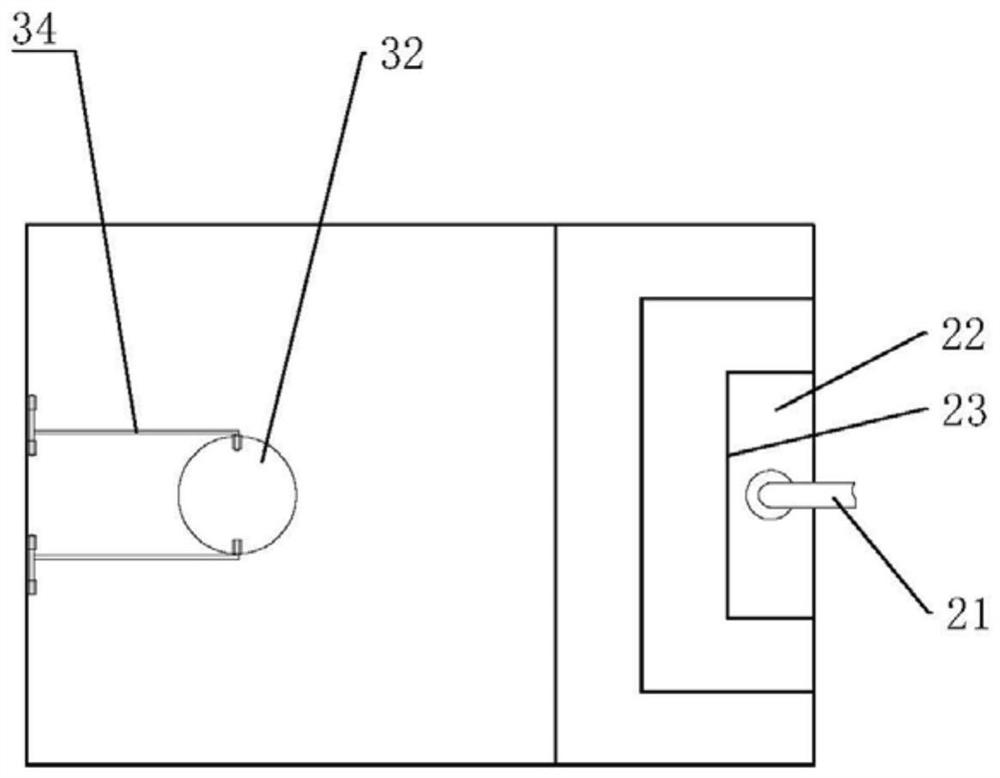

[0034] Example 1: Such as figure 1 with figure 2 As shown, a drainage sedimentation tank using an intelligent zero-discharge drainage method according to the preferred embodiment of the present invention includes a tank body 1, the wall of the tank body 1 is vertical, and the bottom of the tank body 1 is a bucket shape, which is beneficial to particles in the water body Gather. One end of the pool body 1 is provided with a water inlet mechanism, and the other end is provided with a water outlet mechanism. The bottom of the pool body 1 is provided with a mud discharging mechanism. The mud discharging mechanism is an air lift mud discharging or a special scraper and suction machine. The tank body 1 is provided with a level gauge 31 for real-time measurement of the depth of the supernatant in the tank body 1 and the water level in the tank, and the level gauge 31 adopts infrared or ultrasonic. It also includes a control mechanism for controlling the water outlet speed of the wat...

Embodiment 2

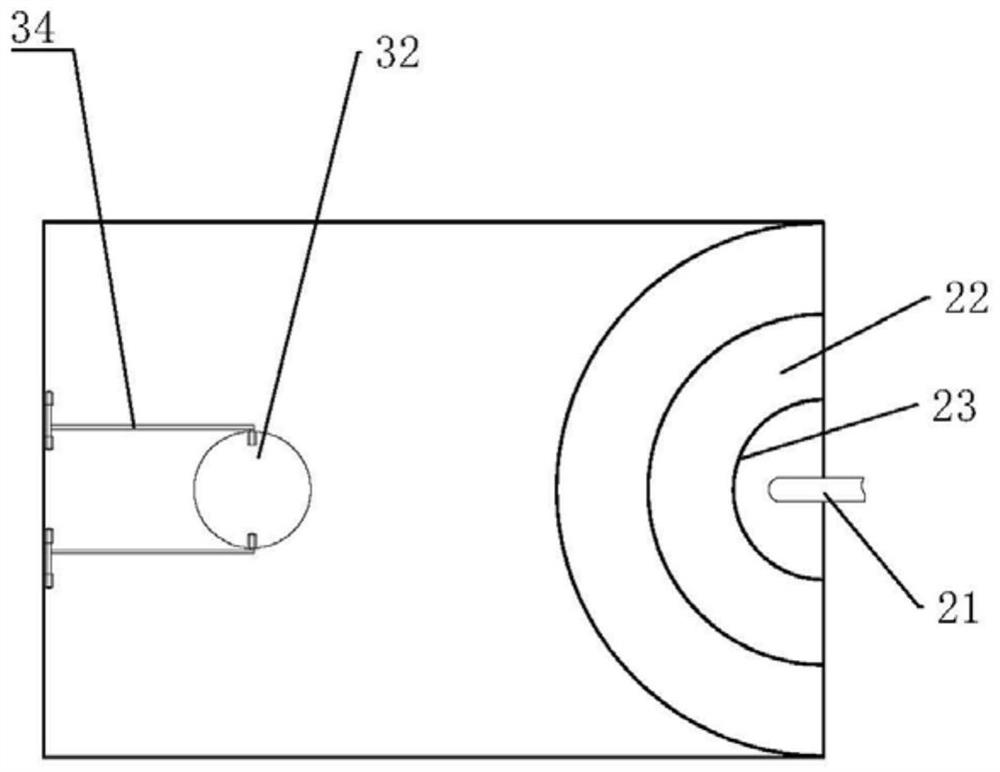

[0038] Example 2: Such as image 3 As shown, a drainage sedimentation tank using an intelligent zero-discharge drainage method is different from Embodiment 1 in that the three-stage water distribution chamber 22 is a semicircular chamber that gradually increases in a direction away from the water inlet pipe 21.

Embodiment 3

[0039] Example 3: Such as Figure 4 As shown, a drainage sedimentation tank using an intelligent zero-discharge drainage method is different from Embodiment 1 in that the bottom of the tank body 1 is a flat bottom.

[0040] An intelligent zero-discharge drainage method of the present invention includes the following steps:

[0041] S1: Set a fixed value H according to the disturbance depth generated when the drain pump is running normally and taking water Assume , H Assume Is the maximum value that does not disturb the precipitation zone;

[0042] S2: After the water in the tank is completed, the water in the tank starts to settle and purify, and the first stage supernatant depth H in the tank is measured. 1 Reach H Assume Time t, the initial sedimentation velocity of particles in the pool V Sink =H Assume / t;

[0043] S3: When the supernatant liquid depth H 1 Reach H Assume When the drain pump starts to work;

[0044] S4: According to V Sink Determine the water outlet speed V water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com