Adding and stirring device for desulfurization gypsum improver

A desulfurization gypsum and stirring device technology, applied in the field of material processing, can solve the problems of low feeding efficiency, affecting efficiency, affecting the accuracy of feeding amount, etc., and achieve the effects of improving feeding efficiency, preventing material blocking, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

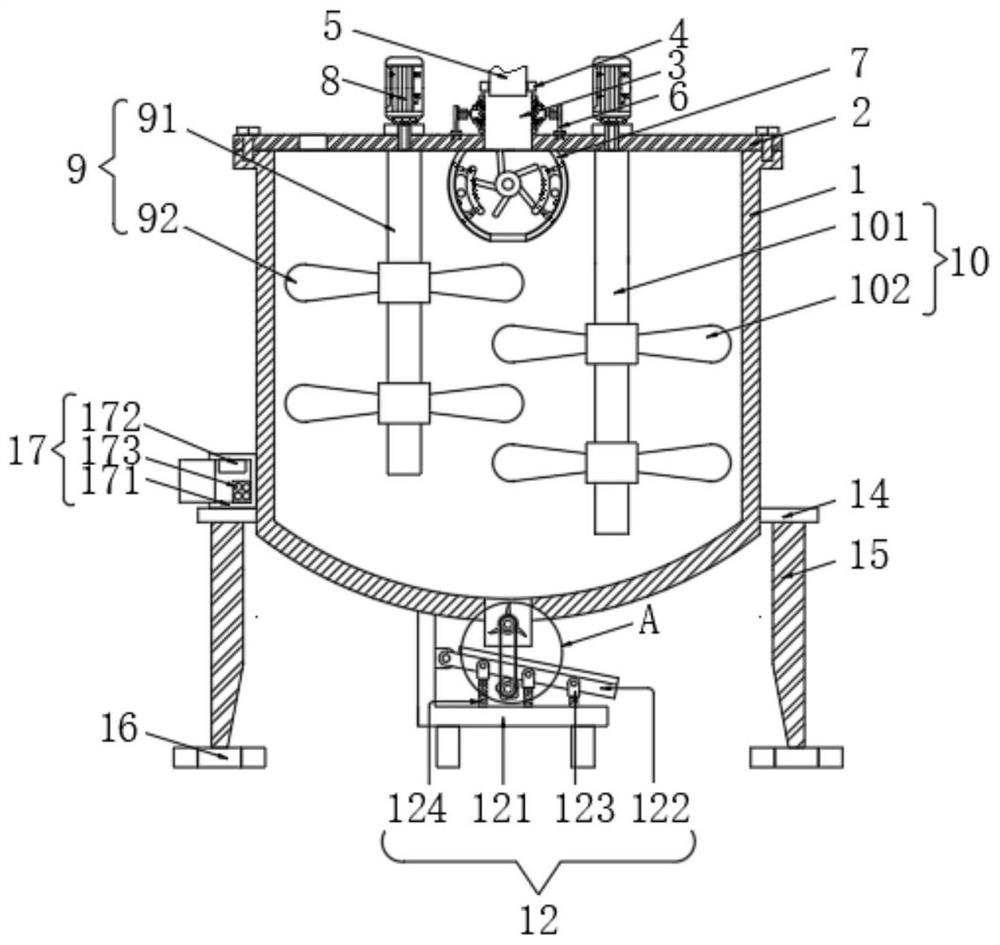

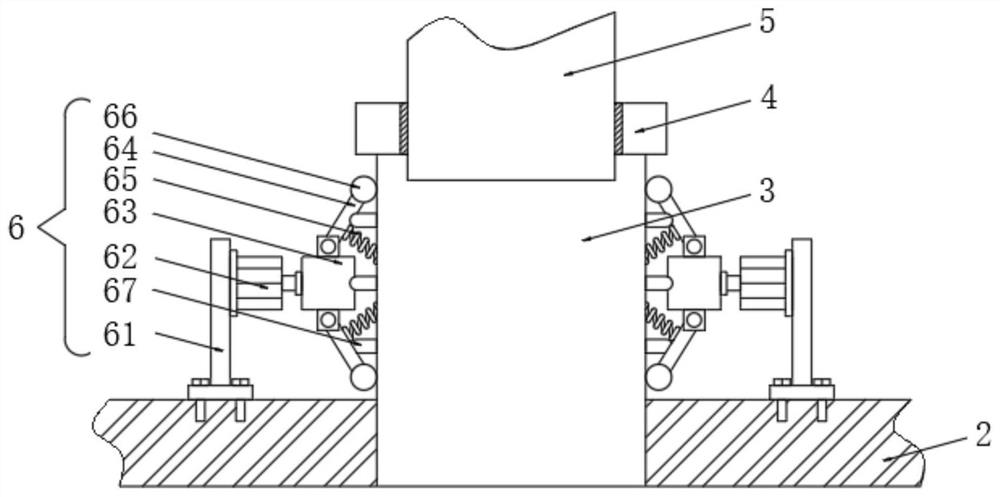

[0028] The invention provides a technical solution: a device for adding and stirring a desulfurized gypsum modifier, please refer to figure 1 , including the mixing tank 1, the top of the mixing tank 1 is fixedly connected with the tank cover 2 by bolts around the top, the top left side of the tank cover 2 is provided with a water inlet for adding water to the mixing tank 1, and the middle part of the tank cover 2 is fixed The feed port 3 is connected, the top of the feed port 3 is movably connected with a cover body 4, the middle part of the cover body 4 runs through a feeding tube 5, and a sealing ring is filled between the outer wall of the feeding tube 5 and the cover body 4, and the sealing ring It is made of rubber material and acts as a seal. When adding desulfurized gypsum into the mixing tank 1, the cover body 4 cooperates with the feeding pipe 5, and the feeding port (not shown in the figure) of the feeding pipe 5 is provided with a storage device for desulfurized gyp...

Embodiment 2

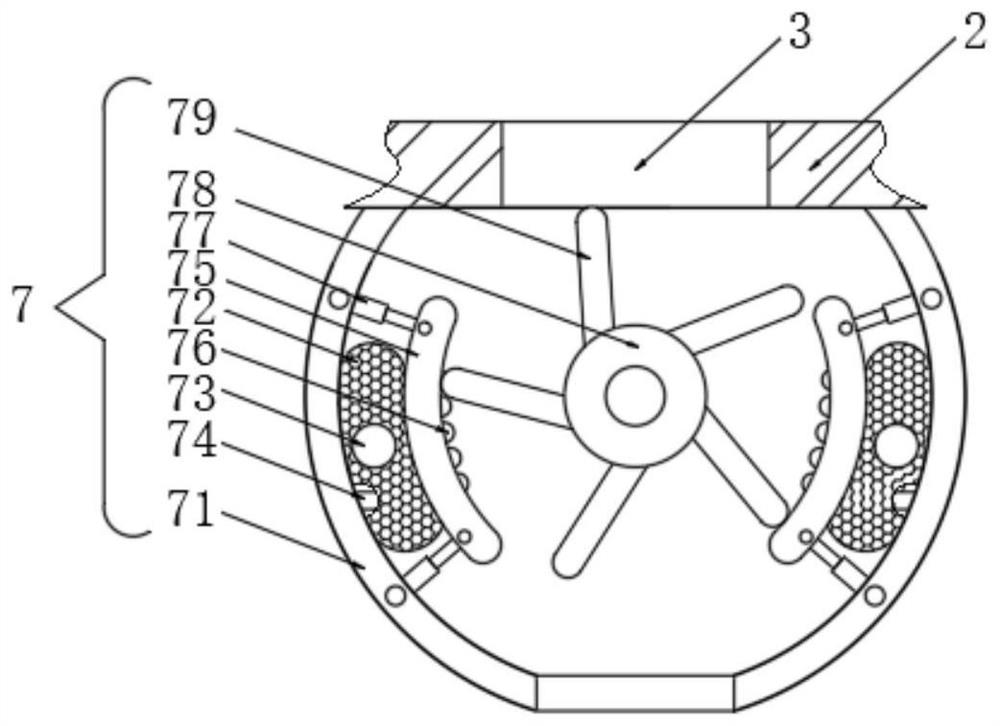

[0037] see image 3 , and embodiment 1 is different: the premixing assembly 7 includes the premixing tank 71 that communicates with the feed port 3, the bottom of the premixing tank 71 is provided with a through groove, and the inner walls on both sides of the premixing tank 71 are connected with water Bag 72, the front side of water bag 72 communicates with one end of water adding pipe 73, the other end of water adding pipe 73 runs through mixing tank 1 and communicates with the water delivery port of water pump (not shown in the figure), and the inside of water bag 72 is provided with water level sensor 74, the model of the water level sensor 74: DLK201, the opposite sides of the two groups of water bags 72 are connected with the pressure plate 75, the pressure plate 75 is evenly opened with through holes, and the opposite sides of the two groups of water bags 72 are uniformly connected with the nozzle 76, and The radius of the nozzle 76 is greater than the radius of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com