Ballast water TRO neutralization treatment system and ship

A treatment system and technology for ballast water, which is applied in ships and the field of ships, can solve problems such as neutralization treatment device failure, submersion below the water surface, failure of TRO analyzer measurement components, etc., to improve stability and reliability, meet Automated operation requirements and the effect of reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

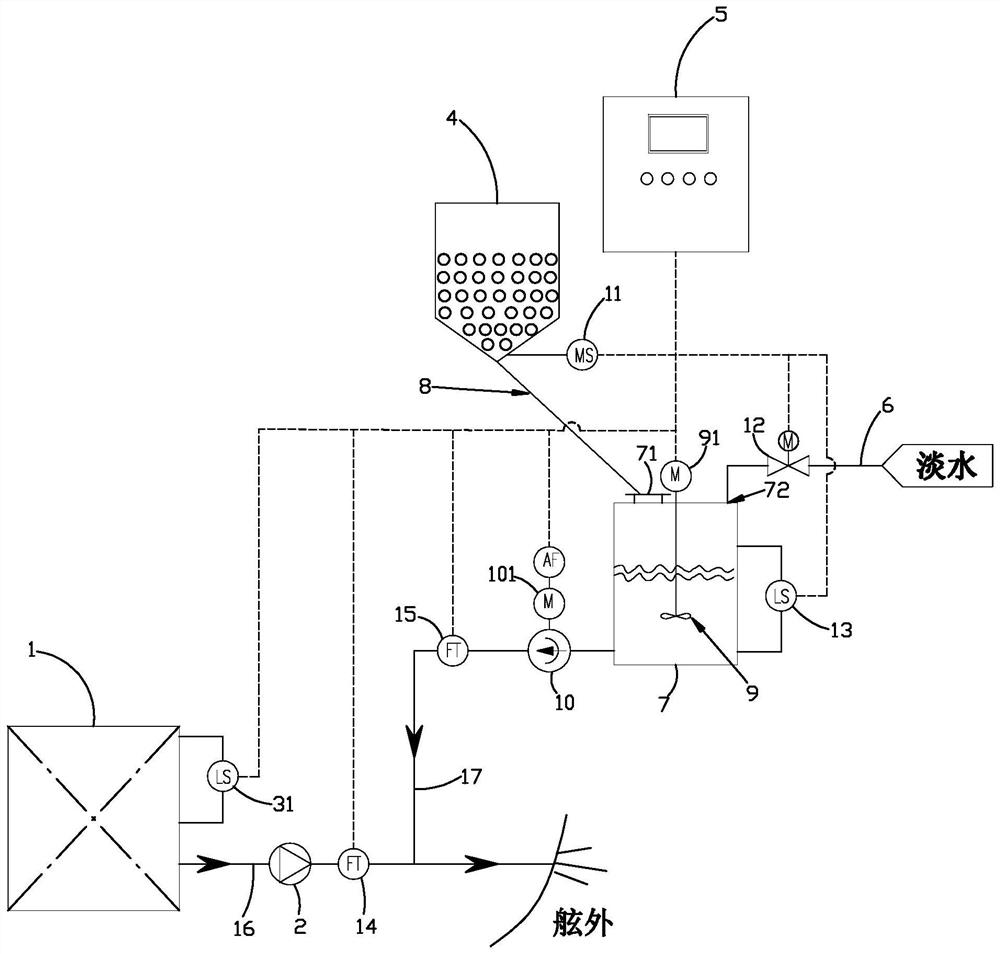

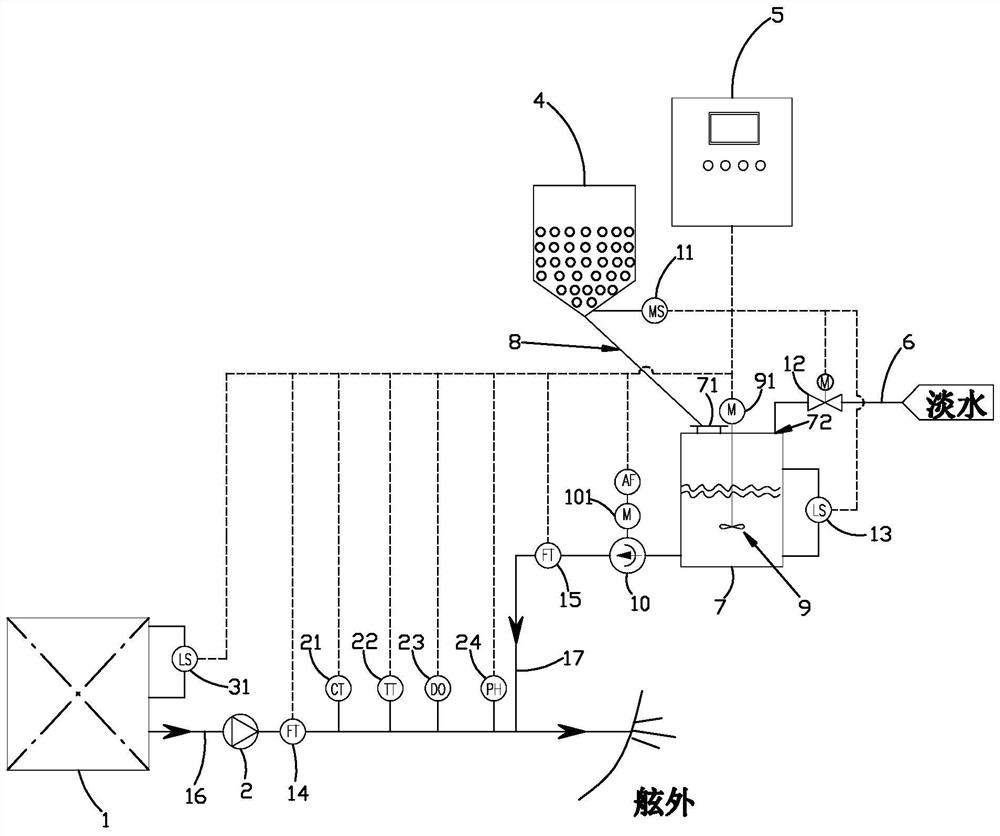

[0024] Such as figure 1 As shown, the ballast water TRO (total residual oxidant, total residual oxide) neutralization treatment system provided by the first embodiment of the present invention includes a ballast tank 1, a ballast pump 2, a neutralizer storage tank 4, and a control system 5. Fresh water pipeline 6, neutralization solution tank 7, neutralizer distribution device 8, neutralizer dosing pump 10, control valve 12, discharge pipeline 16 and neutralization dosing pipeline 17, neutralizer storage Solid neutralizing agent is stored in the tank 4;

[0025] The outlet of the ballast tank 1 is connected to the outboard through the discharge pipeline 16, the ballast pump 2 is arranged on the discharge pipeline 16, and the outlet of the neutralizer storage tank 4 is connected to the neutralization solution tank through the neutralizer distribution device 8. The neutralizing agent inlet 71 of 7 communicates, the outlet of the fresh water pipeline 6 communicates with the fres...

example

[0053] 1. The ballast pumps and outboard points of the entire ballast piping system of a chemical tanker are all submerged below the water surface. During discharge, the treated ballast water in the ballast tank is directly discharged to the tank through the stripping pump. Overboard, it is not possible to install a suitable TRO analyzer or set up a TRO sampling point for TRO monitoring at the outboard point. After adopting the neutralization treatment system of the present invention, by obtaining the ballast pump flow rate, the residence time of the treated ballast water in the ballast tank and other information, a neutralizer solution with a suitable concentration is automatically prepared. After the discharge starts, The control system automatically adjusts the dosing flow rate of the neutralizer dosing pump according to the discharge flow rate to ensure that the TRO in the discharge water is fully and effectively neutralized, meeting the TRO discharge requirements of IMO an...

no. 2 example

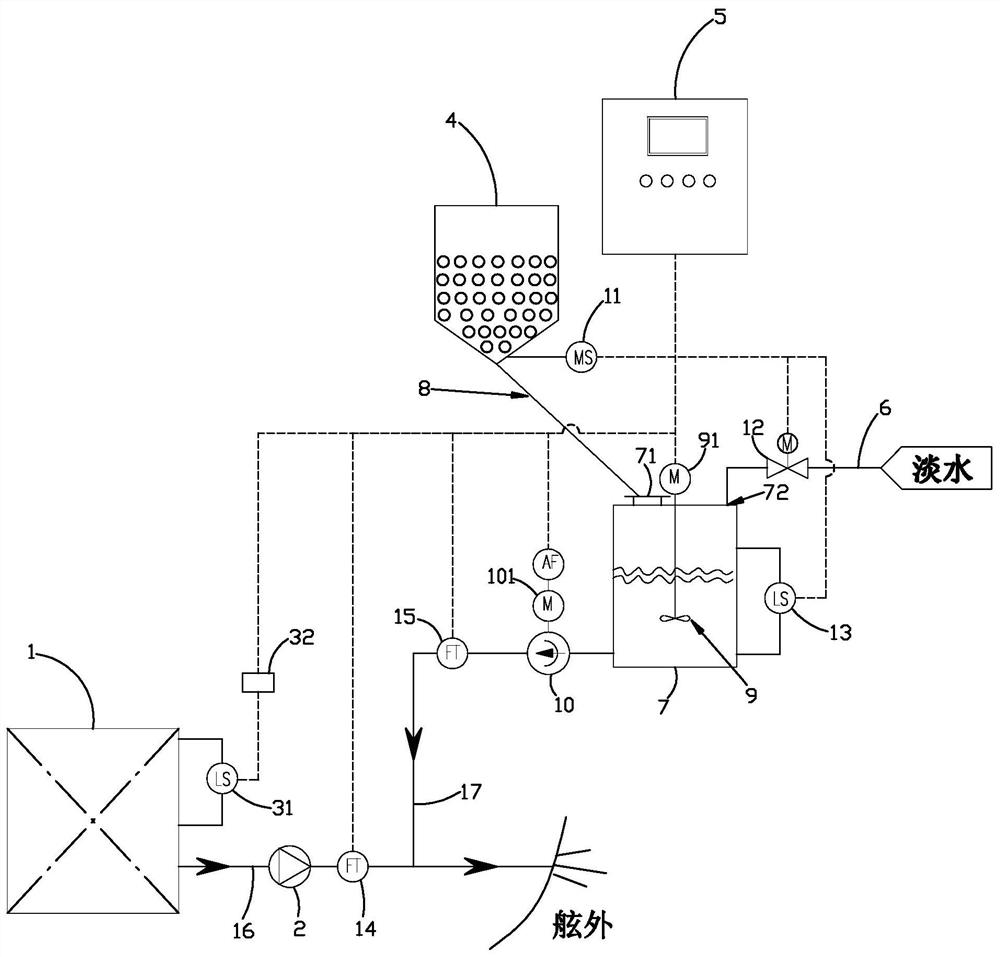

[0056] Such as figure 2 As shown, the ballast water TRO neutralization treatment system provided by the second embodiment of the present invention is substantially the same as that of the first embodiment, except that the method and device for obtaining the ballast water volume are different.

[0057] Specifically, in this embodiment, the ballast water TRO neutralization treatment system further includes a second liquid level gauge 31 and a liquid level telemetry system 32, the second liquid level gauge 31 is arranged on the ballast tank 1, and the liquid level telemetry The system 32 is in signal connection with the second liquid level gauge 31 , and the control system 5 is also in signal connection with the liquid level telemetry system 32 at the same time.

[0058]Due to the different space designs of different ships, the shape of the ballast tank 1 on some ships is irregular, so it is impossible to directly calculate the volume of ballast water in the ballast tank 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com