A kind of adjuvant synergistic heavy oil thermal modification method

A technology of heavy oil and additives, which is applied in the fields of hydrocarbon oil cracking, hydrocarbon oil treatment, petroleum industry, etc., and can solve the problem of thermal reaction activity affecting viscosity reduction efficiency, stability of modified oil not mentioned, and stability of modified oil, etc. problems, to achieve the effect of improving stability, improving stability, and improving viscosity reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

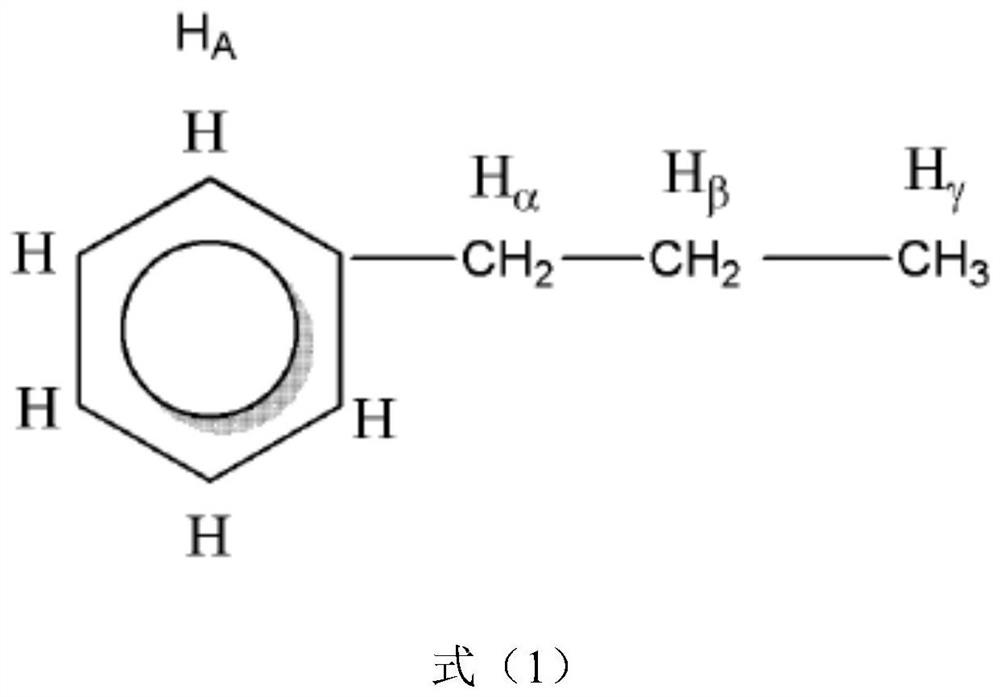

Method used

Image

Examples

Embodiment 1

[0063] With heavy oil HO-A (a heavy vacuum residue, its viscosity at 100 ℃ is 1310mm 2 / s, the asphaltene content is 11.5 wt%) as the raw material for upgrading, and the straight-run industrial distillate DA (with a distillation range of 280-420° C.) is used as the hydrogen donor. The hydrogen donor DA and the amphiphilic surface active substance (diethyl oxalate) were stirred at 100 °C for 1 h to obtain a mixing aid, and then the mixing aid was added to the heavy oil HO-A and stirred at 130 °C for 2 h, The addition amount of hydrogen donor DA is 5wt%, and the addition amount of diethyl oxalate is 250μg / g; the heavy oil HO-A mixed with additives is heated in a nitrogen atmosphere, the initial pressure is 3MPa, and the reaction temperature is 420℃. Upgrading for 10min to obtain the modified oil; the viscosity of the modified oil at 50°C was measured to be 515mm 2 / s, the coke formation rate was 0.04 wt%, and the spot test grade was grade 2.

Embodiment 2

[0071] The heavy oil HO-A is used as the raw material for upgrading, and the straight-run industrial distillate DB (with a distillation range of 250-400°C) is used as the hydrogen donor. The hydrogen donor DB and the amphiphilic surface active substance (dodecylbenzenesulfonic acid) were stirred at 120 °C for 1 h to obtain a mixing aid, and then the mixing aid was added to the heavy oil HO-A at 140 °C Stir for 2h, the addition amount of hydrogen donor DB is 7wt%, and the addition amount of dodecylbenzenesulfonic acid is 300μg / g; the heavy oil HO-A mixed with additives is placed in nitrogen atmosphere, initial pressure 3MPa, reaction temperature The modified oil was modified under the thermal reaction conditions of 425 °C for 5 minutes, and the viscosity of the modified oil at 50 °C was measured to be 490 mm. 2 / s, the coke formation rate was 0.03 wt%, and the spot test grade was grade 2.

Embodiment 3

[0073] The heavy oil HO-A is used as the raw material for upgrading, and the straight-run industrial distillate DC (with a distillation range of 250-380°C) is used as the hydrogen donor. The hydrogen donor DC and the amphiphilic surface active substance (isopropanol) were stirred at 80 °C for 1 h to obtain a mixing aid, and then the mixing aid was added to the heavy oil HO-A and stirred at 80 °C for 2 h. The addition amount of hydrogen agent DC was 10wt%, and the addition amount of isopropanol was 100μg / g; the heavy oil HO-A mixed with additives was modified under the thermal reaction conditions of nitrogen atmosphere, initial pressure of 3MPa and reaction temperature of 400℃. After 60 minutes, the viscosity of the modified oil at 50°C was measured to be 530mm. 2 / s, the coke formation rate was 0.05 wt%, and the speckle test grade was grade 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com