Multifunctional oxyhydrogen burner for electric arc furnace steelmaking and energy supply control method

A control method and electric arc furnace technology, which is applied in the steel manufacturing process, electric furnace, furnace, etc., can solve the problems that are not conducive to the green and low-carbon production of electric arc furnaces, and achieve the effects of preventing tempering and explosion, strengthening the stirring effect, and extending the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

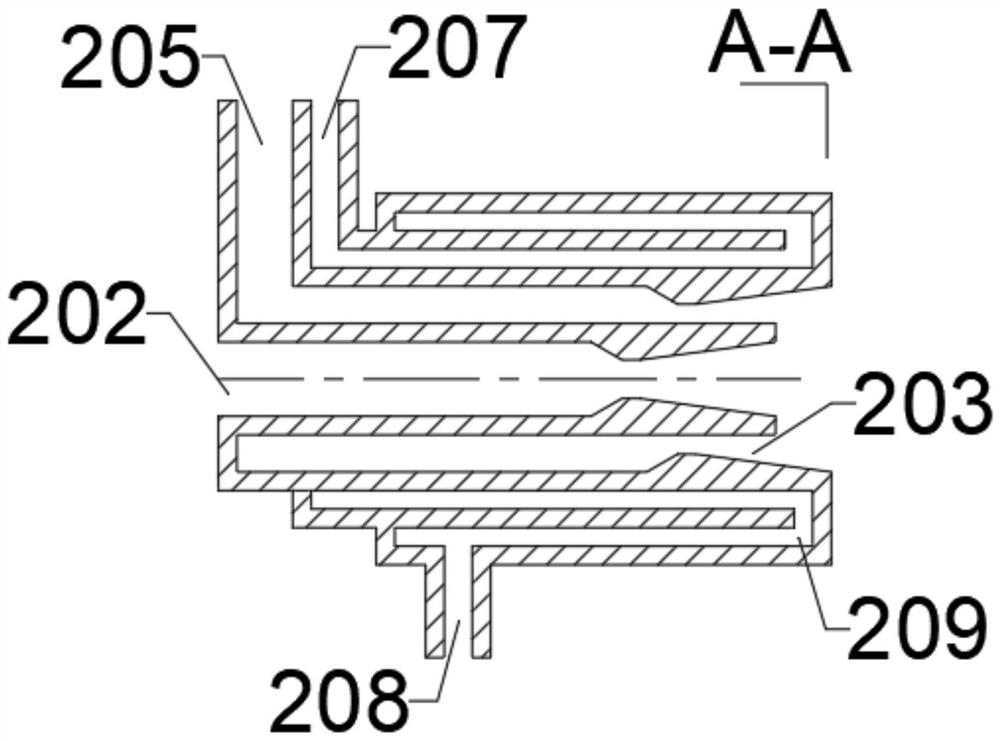

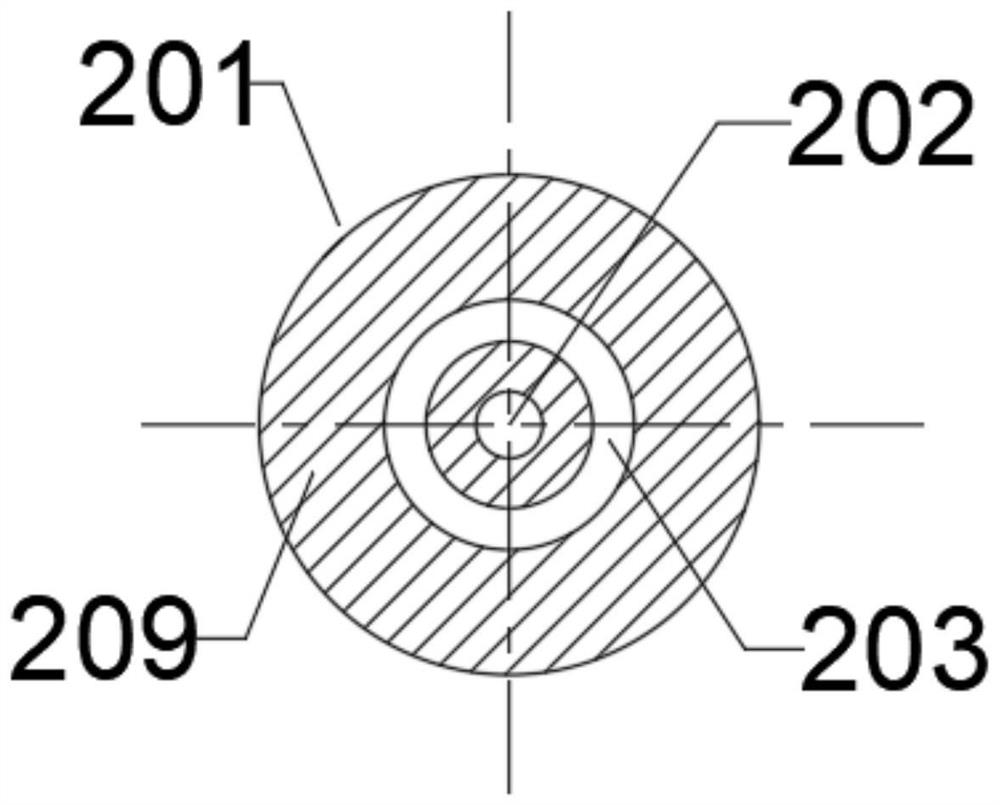

[0036] Such as Figure 2-3 As shown, the present invention implements a single-layer circular seam hydrogen-oxygen burner, the outer wall of the burner body is provided with the water-cooled holster, and the outlet of the main oxygen nozzle adopts a contraction section-expansion section design, A supersonic jet flow can be realized, and a hydrogen annular sleeve for forming a hydrogen accompanying flow is provided on the outside of the main oxygen nozzle. Further, the outlet of the hydrogen annular sleeve adopts a contraction section-expansion section design;

[0037] Further, the Mach number at the outlet of the main oxygen nozzle is 1.7, and the design flow rate of the main oxygen is 2000Nm 3 / h, the pressure is 0.8Mpa; the Mach number of the outlet of the hydrogen annular casing is 1.5, and the design flow rate of the hydrogen accompanying flow is 1200Nm 3 / h, the pressure is 1.2MPa;

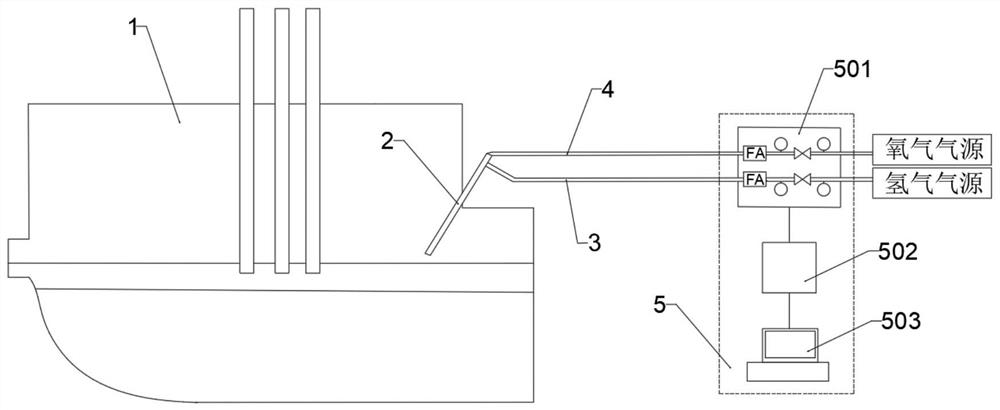

[0038] The embodiment of the present invention is applied to a 70t steelmaking electric...

Embodiment 2

[0050] Such as Figure 5-6 As shown, a hydrogen-oxygen burner with two layers of annular seams is implemented in the present invention. The outer wall of the burner body is provided with the water-cooled lance sleeve, and the outlet of the main oxygen nozzle adopts a contraction section-expansion section design, The main oxygen nozzle that can realize supersonic jet flow, the outside of the main oxygen nozzle is provided with 2 layers of hydrogen annular seam casing and oxygen annular seam casing for forming hydrogen accompanying flow and oxygen accompanying flow; further, The hydrogen annular seam casing and the oxygen annular seam casing are alternately arranged around the main oxygen nozzle, from inside to outside, the first layer is the hydrogen annular seam casing, and the second layer is the oxygen annular seam Sleeve, further, the outlet of the hydrogen annular sleeve and the outlet of the oxygen annular sleeve adopts a contraction section-expansion section design.

[...

Embodiment 3

[0064] Such as Figure 8-9 As shown, it is a hydrogen-oxygen burner with 4 layers of annular seams implemented in the present invention. The outer wall of the burner body is provided with the water-cooled lance sleeve, and the center of the oxygen lance body is the outlet and adopts a contraction section-expansion section design. , the main oxygen nozzle that can realize supersonic jet flow, the outside of the main oxygen nozzle is provided with 4 layers of hydrogen annular seam casing and oxygen annular seam casing for forming hydrogen accompanying flow and oxygen accompanying flow; further , the hydrogen annular seam casing and the oxygen annular seam casing are alternately arranged around the main oxygen nozzle, from inside to outside, the first and third layers are the hydrogen annular seam casing, and the second and fourth layers are The oxygen ring seam sleeve, further, the outlet of the hydrogen ring seam sleeve and the oxygen ring seam sleeve adopts a contraction secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com