Aluminum alloy heat treatment device

A heat treatment device and aluminum alloy technology, which is applied in the field of aluminum alloy processing, can solve the problems of insufficient cooling time, insufficient heat treatment effect, preheating of aluminum alloy workpieces, etc., and achieve the effect of improving the heat treatment effect and enhancing the heat treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

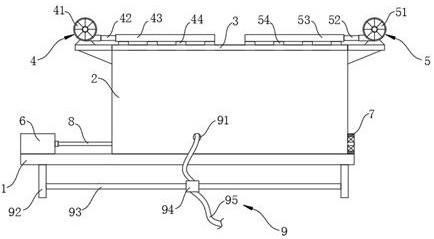

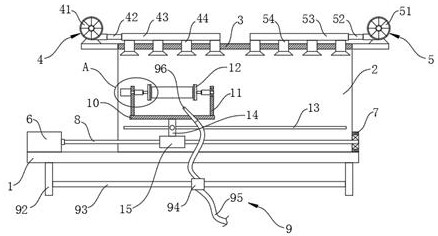

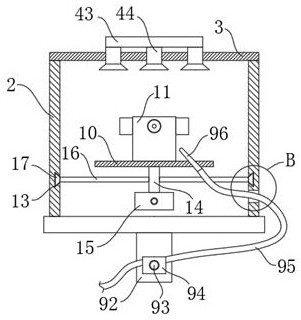

[0026] refer to Figure 1-7 , an aluminum alloy heat treatment device, comprising a bottom plate 1, two ends on one side of the upper surface of the bottom plate 1 are respectively fixedly connected with a support plate 2, the upper ends of the two support plates 2 are fixedly connected with a top cover 3, and the upper surface of the top cover 3 is one One side is fixedly connected with a first heat treatment mechanism 4, and the other side of the upper surface of the top cover 3 is fixedly connected with a second heat treatment mechanism 5. The first heat treatment mechanism 4 in this design adopts the preheating temperature for heat treatment of aluminum alloy workpieces, and the first heat treatment Mechanism 4 is used to preheat the aluminum alloy workpiece; and the second heat treatment mechanism 5 in this design adopts the formal heating temperature for the heat treatment of the aluminum alloy workpiece, and the second heat treatment mechanism 5 is used to perform formal...

Embodiment 2

[0032] refer to Figure 1-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the first heat treatment mechanism 4 includes a first hot air blower 41, and the first hot air blower 41 is fixedly connected to one end of the top cover 3, and the first hot air blower 41 One end of the output port of the output port is fixedly communicated with a first air pipe 42, and one end of the first air pipe 42 is fixedly communicated with a first air pipe 43, and the lower surface of the first air pipe 43 is evenly connected with a plurality of first air outlet pipes 44, and several Each of the first air outlet pipes 44 respectively penetrates to the bottom of the top cover 3, and the staff controls the first hot air blower 41 so that the temperature of the hot air generated in the first hot air blower 41 reaches the preheating temperature for the heat treatment of aluminum alloy workpieces. , and then the hot air is transported to the firs...

Embodiment 3

[0034] refer to Figure 1-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the second heat treatment mechanism 5 includes a second hot air blower 51, and the second hot air blower 51 is fixedly connected to one end of the top cover 3, and the second hot air blower 51 One end of the output port of the output port is fixedly communicated with a second air pipe 52, and one end of the second air pipe 52 is fixedly communicated with a second air pipe 53, and the lower surface of the second air pipe 53 is evenly connected with a plurality of second air outlet pipes 54, and several Each of the second air outlet pipes 54 runs through the bottom of the top cover 3 respectively, and the staff controls the second hot air blower 51 so that the temperature of the hot air generated in the second hot air blower 51 reaches the official heating temperature for the heat treatment of aluminum alloy workpieces. , and then the hot air is transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com