K418 mother alloy vacuum induction melting element control method

A technology of vacuum induction melting and control method, which is applied in the field of superalloy smelting, which can solve the problems of high burning loss, difficulty, and reduced mechanical properties, and achieve the effects of wide application range, improved purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

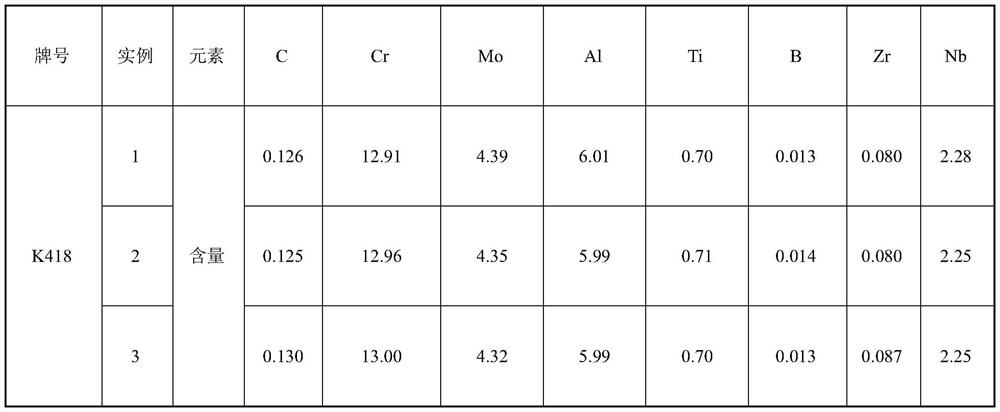

Examples

Embodiment 1

[0019] Vacuum induction melting of K418 master alloy.

[0020] Step 1, raw material baking

[0021] Carbon, metal nickel, metal chromium, metal molybdenum, metal aluminum, metal titanium, metal niobium, nickel-boron alloy and metal zirconium raw materials are baked at 100°C for 3 hours.

[0022] Step 2, according to the order of feeding and smelting

[0023] 2.1 Add Ni, C, Mo and Cr raw materials, and when the smelting chamber is evacuated to no more than 20Pa, the power is stepped up until the molten metal is melted.

[0024] 2.2 Entering the refining period, when the pressure in the smelting chamber is not greater than 5Pa, adjust the temperature of the molten metal to 1530°C, and then adjust the power to the heat preservation power for 40 minutes of refining time. After the refining is completed, the pressure in the smelting chamber is not greater than 5Pa.

[0025] 2.3 Add Al, Ti and Nb raw materials, adjust the temperature of the molten metal to 1400°C, and the pressure...

Embodiment 2

[0030] Vacuum induction melting of K418 master alloy.

[0031] Step 1, raw material baking

[0032] Carbon, metal nickel, metal chromium, metal molybdenum, metal aluminum, metal titanium, metal niobium, nickel-boron alloy and metal zirconium raw materials are baked at 150°C for 3 hours.

[0033] Step 2, according to the order of feeding and smelting

[0034] 2.1 Add Ni, C, Mo and Cr raw materials, and when the smelting chamber is evacuated to no more than 20Pa, the power is stepped up until the molten metal is melted.

[0035] 2.2 Entering the refining period, when the pressure in the smelting chamber is not greater than 5Pa, adjust the temperature of the molten metal to 1540°C, and then adjust the power to the heat preservation power for 60 minutes of refining time. After the refining is completed, the pressure in the smelting chamber is not greater than 5Pa.

[0036] 2.3 Add Al, Ti and Nb raw materials, adjust the temperature of the molten metal to 1450°C, and the pressure...

Embodiment 3

[0041] Vacuum induction melting of K418 master alloy.

[0042] Step 1, raw material baking

[0043] Carbon, metal nickel, metal chromium, metal molybdenum, metal aluminum, metal titanium, metal niobium, nickel-boron alloy and metal zirconium raw materials are baked at 150°C for 3 hours.

[0044] Step 2, according to the order of feeding and smelting

[0045] 2.1 Add Ni, C, Mo and Cr raw materials, and when the smelting chamber is evacuated to no more than 20Pa, the power is stepped up until the molten metal is melted.

[0046] 2.2 Entering the refining period, when the pressure in the smelting chamber is not greater than 5Pa, adjust the temperature of the molten metal to 1550°C, and then adjust the power to the heat preservation power for 80 minutes of refining time. After the refining is completed, the pressure in the smelting chamber is not greater than 5Pa.

[0047] 2.3 Add Al, Ti and Nb raw materials, adjust the temperature of the molten metal to 1480°C, and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com