Rapier loom with automatic adjusting function

A rapier loom, automatic adjustment technology, applied in the field of textile printing and dyeing, can solve the problems of reducing processing efficiency, weft damage, large friction, etc., and achieve the effect of improving the overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

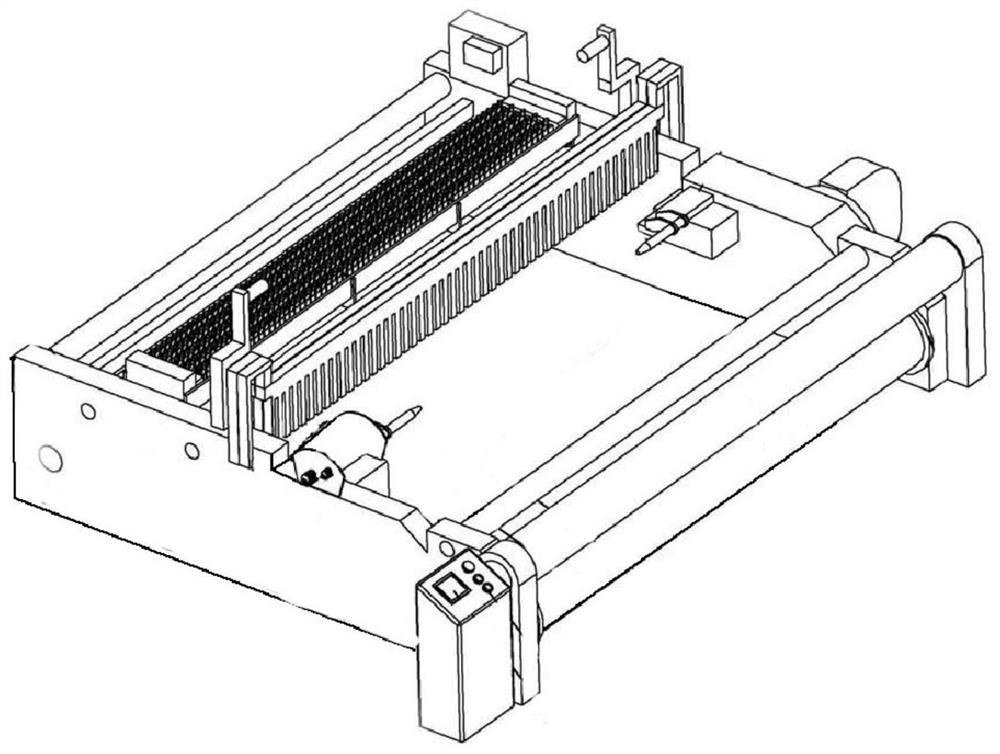

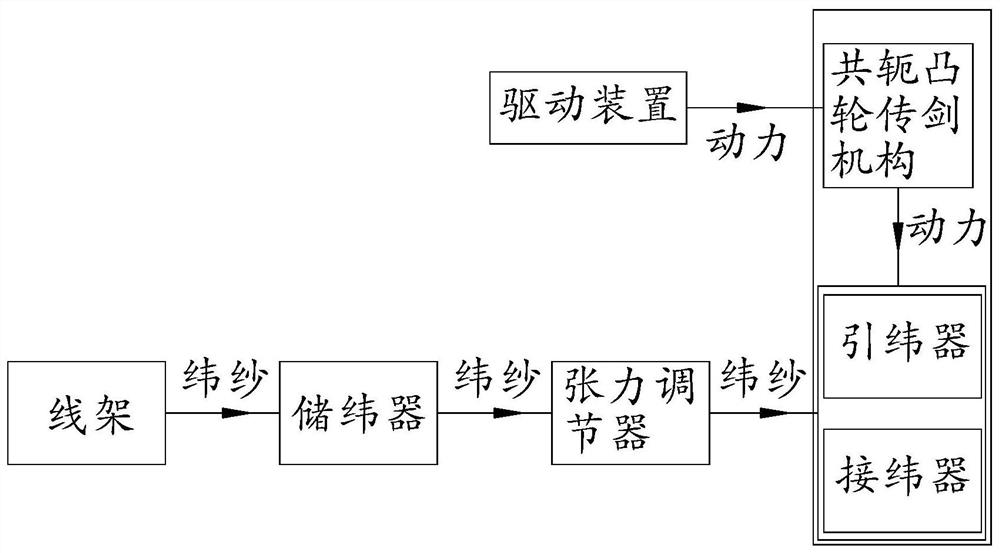

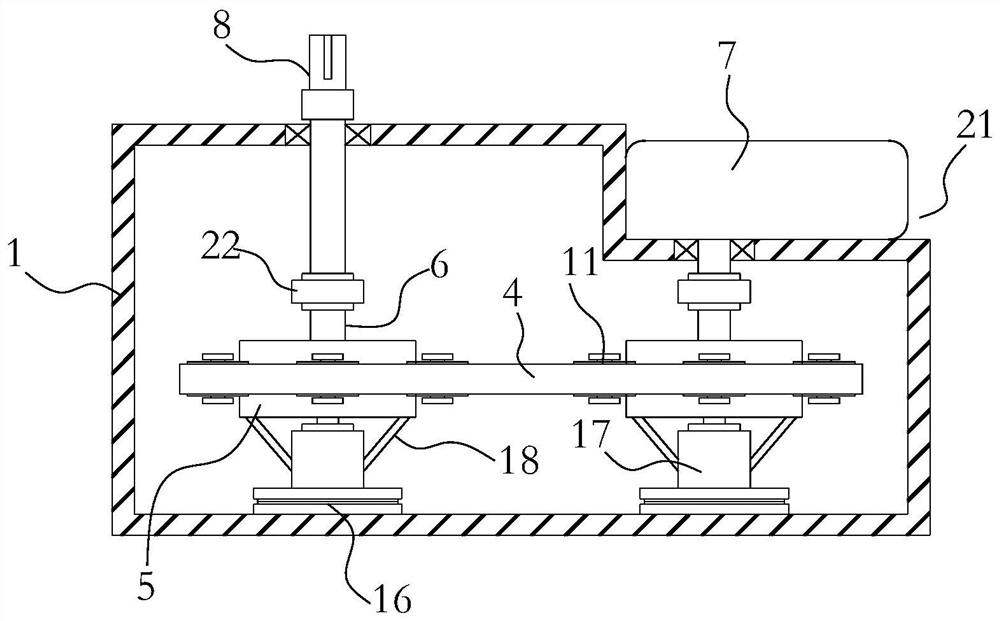

[0035] like figure 1 As shown, a rapier loom with automatic adjustment function is the same as the traditional rapier loom, and it also includes a frame and a warp let-off mechanism, a shedding mechanism, and a rapier weft insertion mechanism arranged on the frame. , Weft beating mechanism and winding mechanism. At the same time, if figure 2 As shown, the rapier type weft insertion mechanism also includes a thread frame, a weft feeder, a tension regulator, a weft insertion device and a weft connection device, etc., and the rapier type weft insertion mechanism is used for weft yarn insertion and insertion. Weft insertion. In view of a series of problems existing in the current traditional rapier loom, the present invention intends to improve the existing rapier loom from three aspects in order to obtain better comprehensive performance.

[0036] First of all, from the first point of view, the existing rapier looms, for different weft yarns, have a large difference in weft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com