High-elastic plastic runway and construction method thereof

A plastic runway, high-elasticity technology, applied in the direction of roads, roads, buildings, etc., can solve the problems of poor elasticity of plastic runways, and achieve the effects of good mechanical properties and excellent shock absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

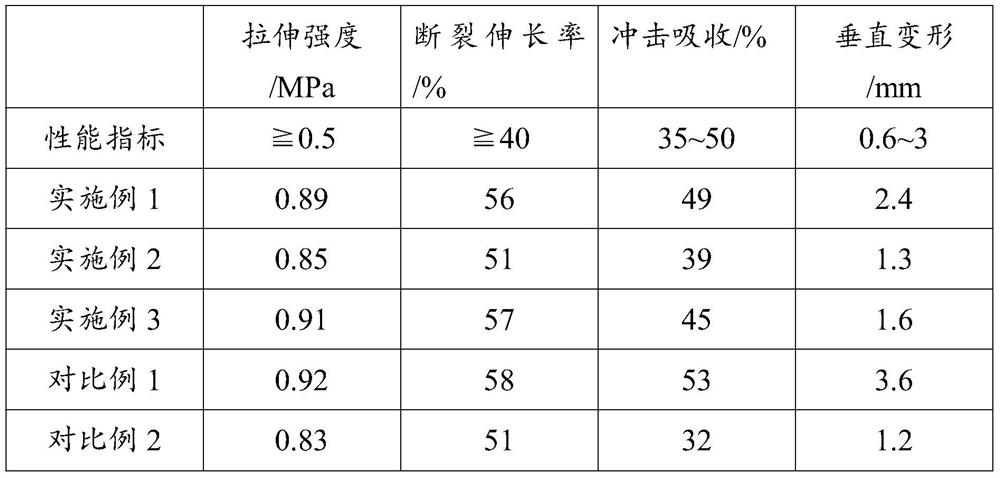

Embodiment 1

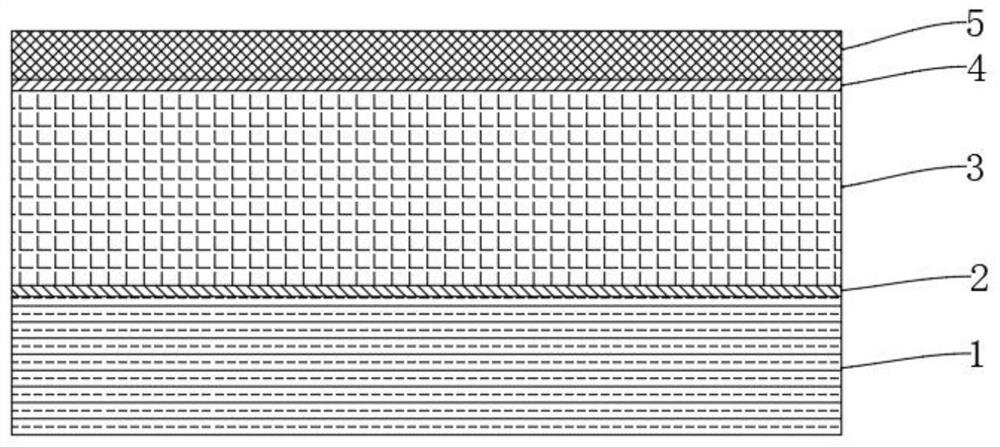

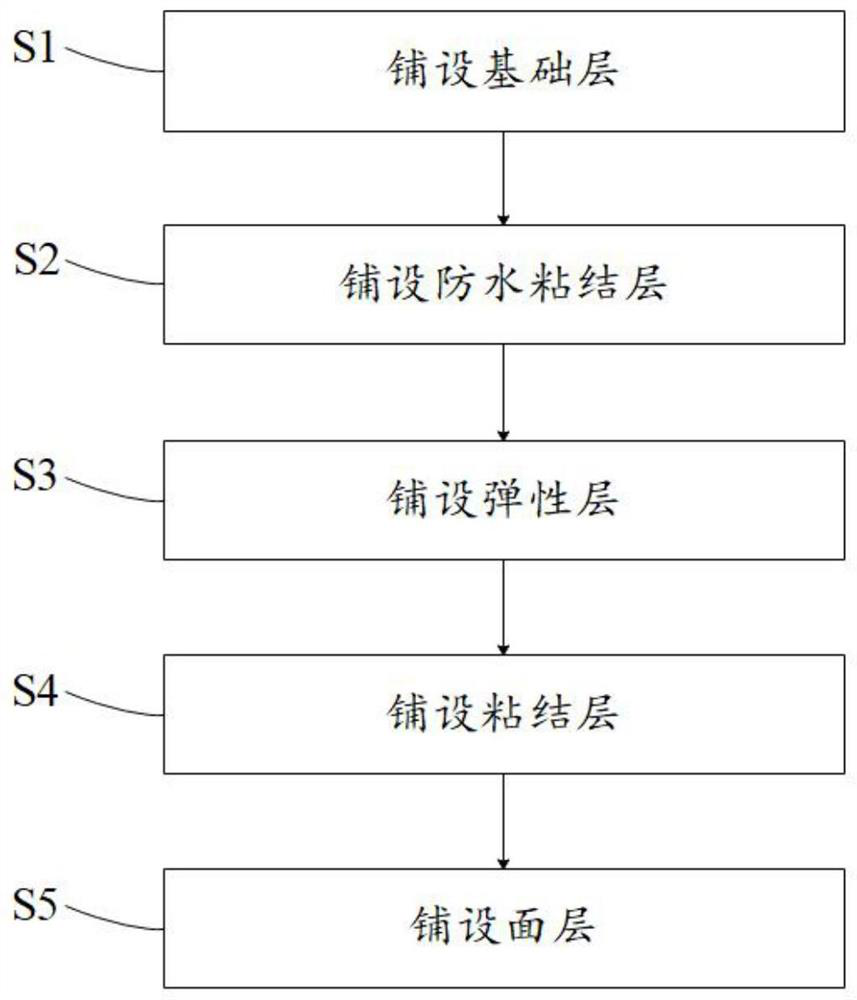

[0037] Embodiment 1 provides a kind of construction method of high-elasticity plastic track, comprising the following steps:

[0038] Lay cement or asphalt on the ground to form a base layer.

[0039] Lay water-based epoxy resin on the base layer to form a waterproof bonding layer.

[0040] A mixture of foamed polyurethane material and EPDM particles in a mass ratio of 1:0.5 is laid on the waterproof adhesive layer to form an elastic layer.

[0041] Lay polyurethane adhesive on the elastic layer to form a bonding layer.

[0042] A mixture of urethane adhesive and EPDM particles in a mass ratio of 1:6 is laid on the bonding layer to form a surface layer.

[0043] In the high elastic plastic track obtained in Example 1, the thickness of the base layer is 3cm, the thickness of the waterproof adhesive layer is 0.3mm, the thickness of the elastic layer is 12mm, the thickness of the adhesive layer is 0.3mm, and the thickness of the surface layer is 2mm .

Embodiment 2

[0045] Embodiment 2 provides a kind of construction method of high-elasticity plastic track, comprising the following steps:

[0046] Lay cement or asphalt on the ground to form a base layer.

[0047] Lay water-based epoxy resin on the base layer to form a waterproof bonding layer.

[0048] A mixture of foamed polyurethane material and EPDM particles in a mass ratio of 1:2 is laid on the waterproof adhesive layer to form an elastic layer.

[0049] Lay polyurethane adhesive on the elastic layer to form a bonding layer.

[0050] A mixture of urethane adhesive and EPDM particles in a mass ratio of 1:5 is laid on the adhesive layer to form a surface layer.

[0051] In the high elastic plastic track obtained in Example 2, the thickness of the base layer is 3cm, the thickness of the waterproof adhesive layer is 0.3mm, the thickness of the elastic layer is 10mm, the thickness of the adhesive layer is 0.3mm, and the thickness of the surface layer is 4mm .

Embodiment 3

[0053] Embodiment 3 provides a kind of construction method of high-elasticity plastic track, comprising the following steps:

[0054] Lay cement or asphalt on the ground to form a base layer.

[0055] Lay water-based epoxy resin on the base layer to form a waterproof bonding layer.

[0056] A mixture of foamed polyurethane material and EPDM particles in a mass ratio of 1:1 is laid on the waterproof adhesive layer to form an elastic layer.

[0057] Lay polyurethane adhesive on the elastic layer to form a bonding layer.

[0058] A mixture of urethane adhesive and EPDM particles in a mass ratio of 1:5 is laid on the adhesive layer to form a surface layer.

[0059] In the high elastic plastic track obtained in Example 3, the thickness of the base layer is 3cm, the thickness of the waterproof adhesive layer is 0.3mm, the thickness of the elastic layer is 11mm, the thickness of the adhesive layer is 0.3mm, and the thickness of the surface layer is 3mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com