Wafer de-bonding method

A debonding and wafer technology, applied in the field of microelectronic device packaging, can solve the problem that the thin wafer and the carrier can not be separated smoothly during the debonding process, achieve broad application prospects and market potential, avoid fragmentation risks, important strategic significance and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

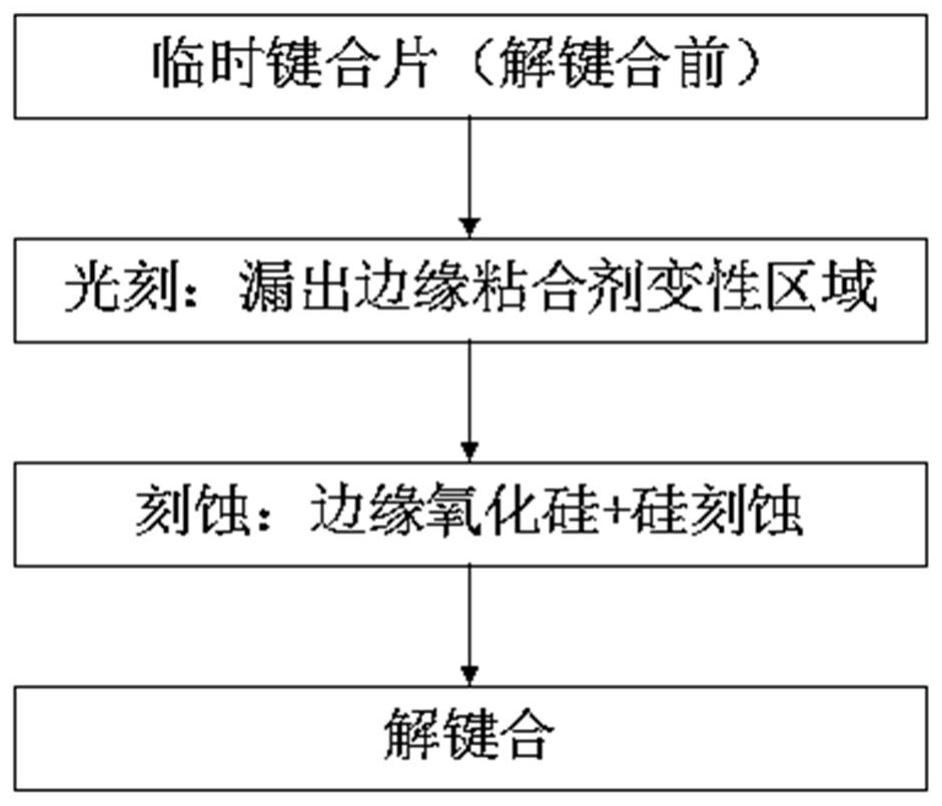

[0038] A wafer debonding method comprises the following steps:

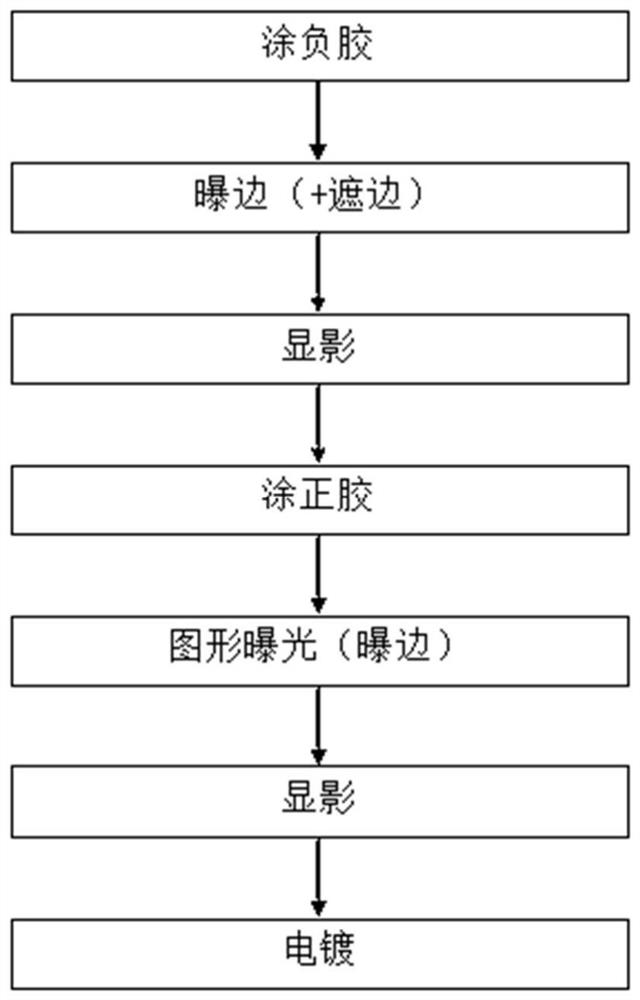

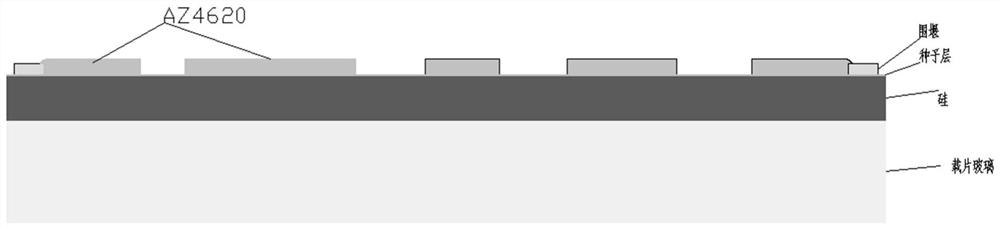

[0039] 1. The RDL layer is patterned before electroplating, and a cofferdam is prepared on the edge of the wafer through a photolithography process (coating, edge exposure, development). The photoresist is a negative photoresist, the model is JSR111, and the thickness of the glue is based on The process can be selected from 5 to 15 μm, and the width of the exposure edge can be selected from 0 to 5 mm (A1) according to the process. When the edge is exposed, the edge is covered with 1.4 mm to ensure that the edge is not covered with glue during electroplating and can conduct electricity normally, and the preparation of the cofferdam is completed. Afterwards, carry out normal patterning processing, and prepare the required pattern by applying glue, exposing and developing. The selected photoresist is a positive photoresist, the model is AZ4620, and the thickness can be selected from 5 to 20 μm according to the proces...

Embodiment 2

[0048] A wafer debonding method comprises the following steps:

[0049] 1. Photolithography in the adhesive denaturation area, glue coating and edge washing to expose the edge adhesive denaturation area, the photoresist model used in the photolithography process is AZ4620, the thickness of the photoresist is 20 μm, and the edge washing width is 6mm, such as Figure 9 shown;

[0050] 2. Use a dry degumming machine for PI etching. The PI material is JSR5100 with a thickness of 3-10 μm. The etching gas used to etch PI in the dry degumming machine is O 2 and CF 4 , O 2 and CF 4 The volume ratios are 75%-95% and 5%-25%, respectively, the microwave power is 1300W, the radio frequency power is 280W, the temperature is 20°C, and the etching time is 100s-500s; the PI material in this example is JSR5100, The thickness is 4 μm, and the etching gas used for etching PI is O 2 and CF 4 , O 2 and CF 4 The flow rates are 800sccm and 40sccm respectively, the wave power is 1300W, the RF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com