Adjustable combined type electronic heat dissipation device

A radiator and combined technology, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problems of narrow application range, inconvenient disassembly and replacement, and reduced heat dissipation efficiency, so as to achieve large heat dissipation and The contact area meets the needs of heat dissipation and improves the effect of heat dissipation energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

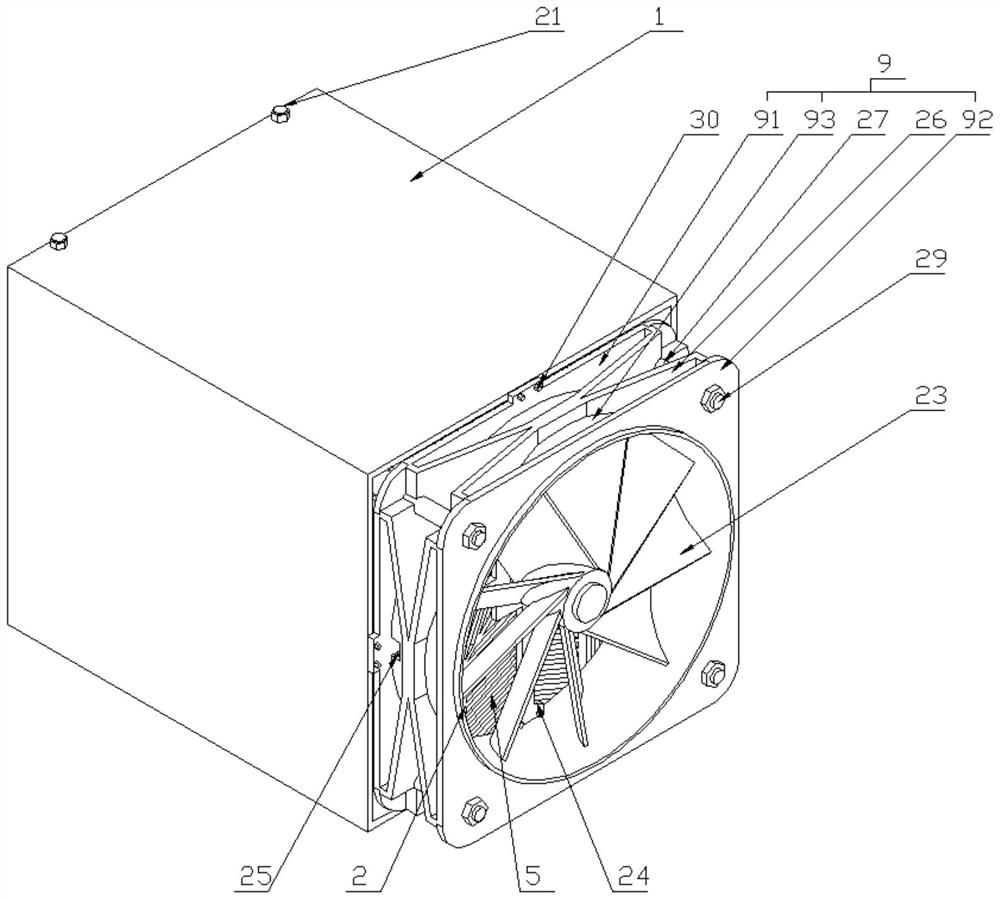

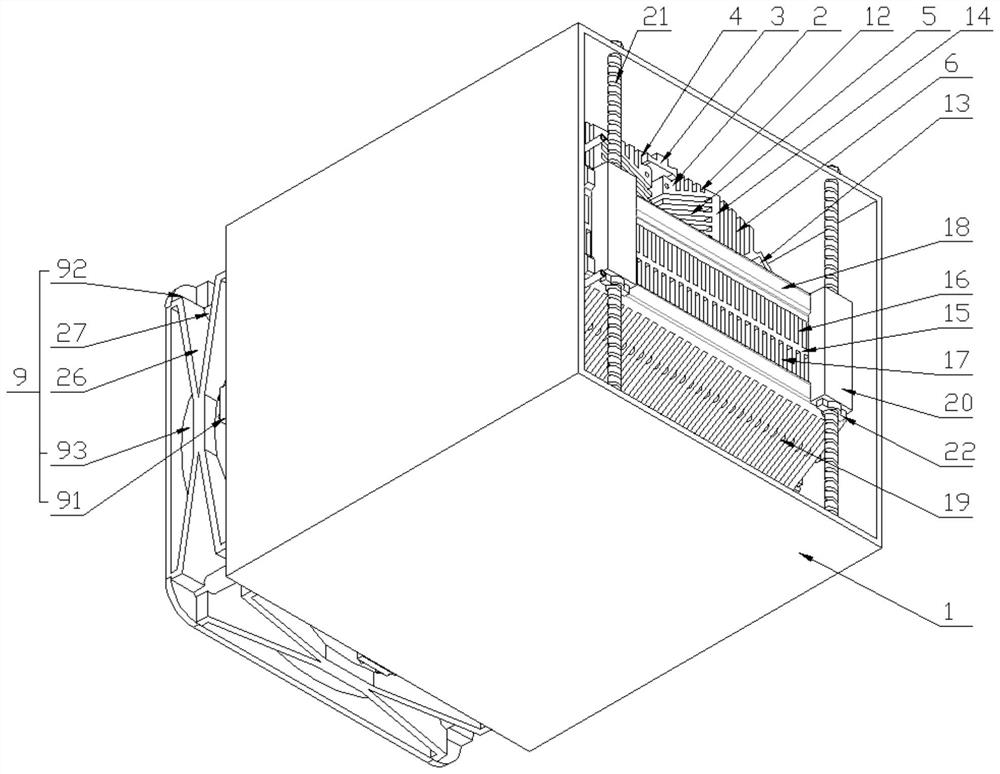

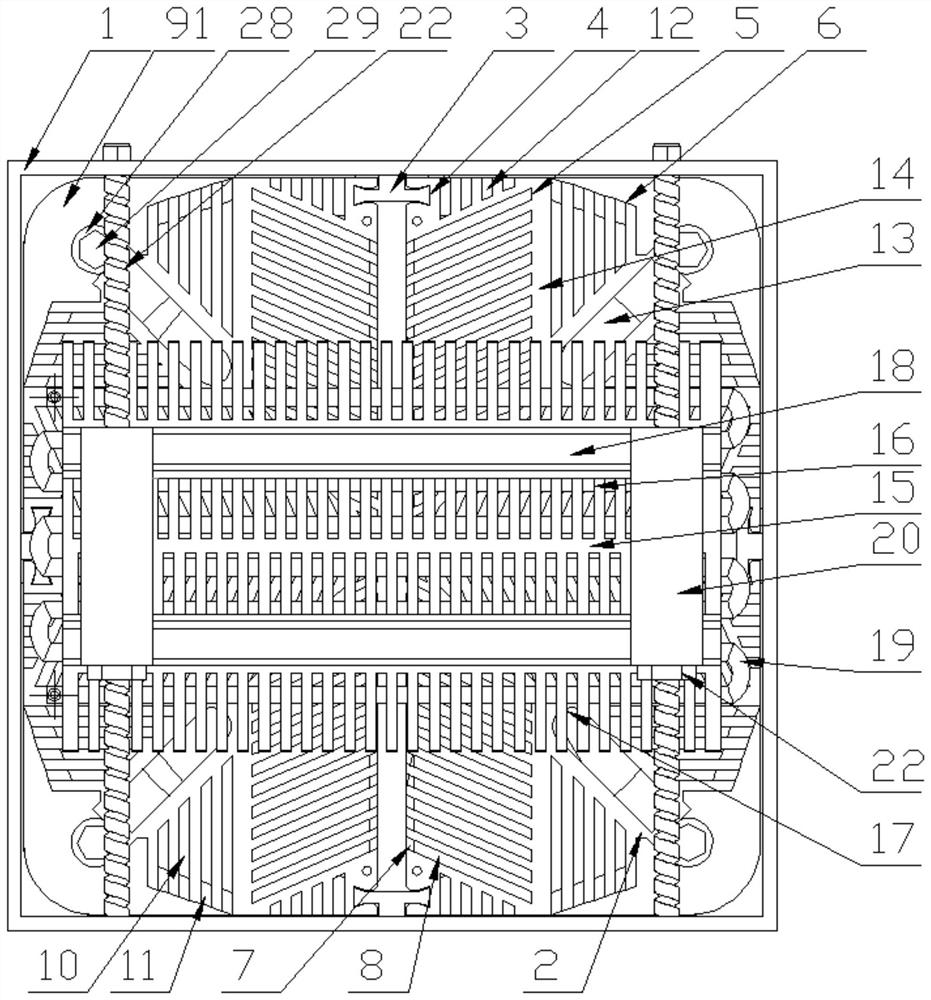

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] An adjustable combined electronic radiator, including a box body 1, wherein, the box body 1 is provided with four angular heat sinks 2 arranged symmetrically at intervals and mated with the inner wall of the box body 1, and the box body 1. A cutting strip 3 is provided on the inner wall, and a socket 4 matching the shape of the cutting strip 3 is provided on the inner wall of the corner radiator 2, and the two ends of the socket 4 are oppositely flared;

[0028] The corner heat sink 2 is provided with a plurality of first notches 5 and second notches 6 arranged symmetrically with respect to the diagonal of the box body 1 and distributed at intervals. The first notch 5 is vertically provided with corners The cooling body 2 is connected with a number of first folded plates 7 and second folded plates 8 arranged in dislocation intervals, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com