Automatic welding production line of corrugated web H-shaped steel for automobile high-strength girder

An automatic welding and high-strength technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to achieve rapid and mass production, corrugated web H-beams without production lines, and high manufacturing costs. Safe and convenient operation and maintenance, compact structure, safe and reliable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

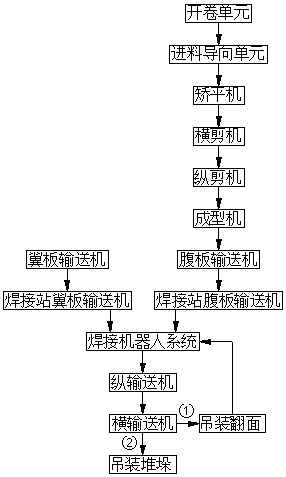

[0064] An automatic welding production line for corrugated web H-beams for automobile high-strength girders, as shown in the figure, including an uncoiling unit 1, a leveling machine 2, a transverse shearing machine 3, a longitudinal shearing machine 4, a forming machine 5, and webs connected in sequence Conveyor 6, welding station web conveyor 7, welding robot system 8, longitudinal conveyor 9, horizontal conveyor 10, and controller;

[0065] It also includes a wing conveyor 11 arranged side by side with the web conveyor 6, and a welding station wing conveyor 12 arranged side by side with the welding station web conveyor 7;

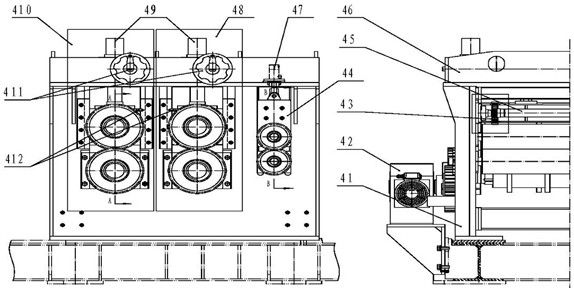

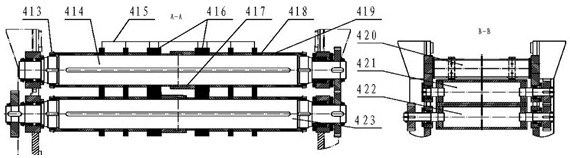

[0066] The forming machine 5 comprises a forming frame, an upper pressing roller part 511 and a lower pressing roller part 514 which are axially connected to the forming frame, and a first driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com