Automatic stroke adjusting mechanism and method for gear machining tool

A processing machine tool and automatic adjustment technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of complex mechanism, increased mechanical and electrical control costs, large volume, etc., and achieve reliable connection and easy quality assurance , sports accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

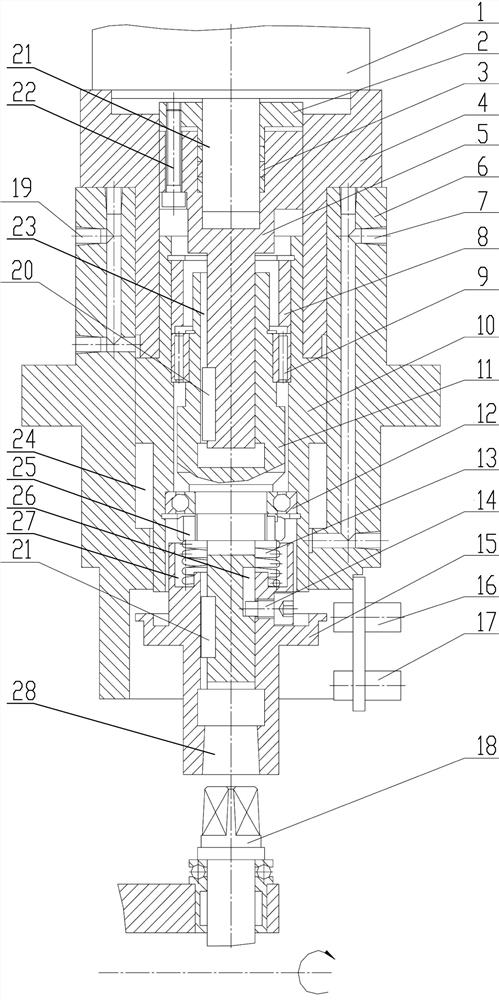

[0029] See figure 1 , An automatic stroke adjustment mechanism for a gear processing machine tool, which includes a support 6 in which a piston cavity 24 is machined, and an oil cylinder piston 10 is installed inside the piston cavity 24. A positioning disk 4 is fixedly installed on the top of the support 6 to block the top of the piston cavity 24; a servo motor 1 is fixedly installed on the top of the positioning disk 4, and the output end of the servo motor 1 is the same as the output shaft. 5 is connected; the bottom end of the output shaft one 5 is matched with the output shaft two 11 through a feather key structure, and drives the output shaft two 11 to rotate; the output shaft two 11 is positioned and installed inside the cylinder piston 10 through a bearing assembly, The piston 10 of the oil cylinder drives it to slide along the axial direction; the piston cavity 24 is connected with the oil supply structure for driving its movement; the lower part of the output shaft 11...

Embodiment 2

[0040] A method for adjusting the stroke of the automatic stroke adjustment mechanism of a gear processing machine tool:

[0041] Step 1: Supply oil through the oil inlet and outlet holes No. 19, return oil through the oil inlet and outlet holes No. 7, and the cylinder piston 10 moves downward, driving the output shaft No. 11 and the connecting square head 15 to move downwards, connecting the square head 15 with the drive screw After the outer square head of 18 is fully fitted, the cylinder piston 10 continues to move downwards, compressing the compression spring 13 until the lower end of the cylinder piston 10 fits with the end surface of the support 6, and the sending head 17 sends a signal;

[0042] Step 2: Servo motor 1 rotates to drive output shaft one 5, output shaft two 11, connecting square head 15, and drive screw 18 to rotate. After the drive screw 18 drives the motion mechanism to the specified position, the servo motor 1 stops rotating;

[0043] Step 3: Oil inlet 7 enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com