Quick grooving equipment for wooden washboard processing

A washboard and fast technology, which is applied in the direction of wood processing equipment, slotting machines, manufacturing tools, etc., can solve the problems of uniform planing intervals, messy work sites, and a lot of air dust, so as to achieve uniform planing, ensure cleanliness, The effect of preventing sawdust from splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

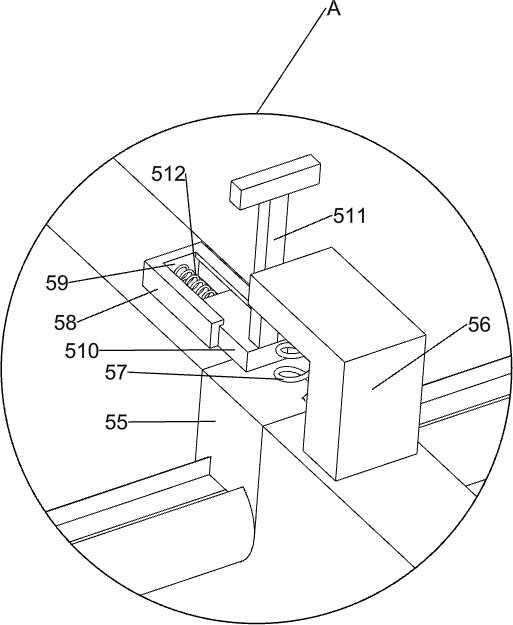

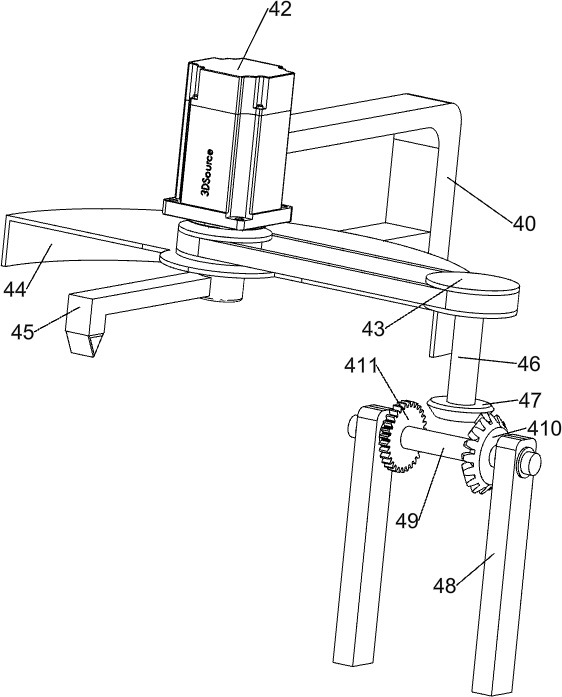

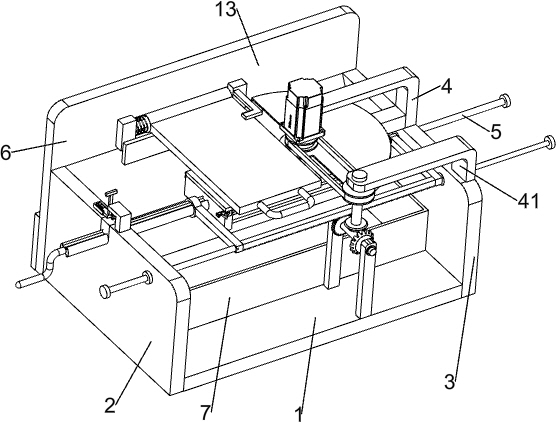

[0023] A kind of fast grooving equipment for wooden washboard processing, such as Figure 1-5 As shown, it includes a bottom plate 1, a first support plate 2, a second support plate 3, a cutting mechanism 4 and a matching mechanism 5. The left side of the bottom plate 1 is provided with the first support plate 2, and the right side of the bottom plate 1 is provided with the second support plate. 3. A cutting mechanism 4 is provided on the second support plate 3 , and a matching mechanism 5 is connected between the first support plate 2 and the second support plate 3 .

[0024] When the user needs to process and plan the washboard, this equipment can be used. First, the washboard that needs to be planed is placed in the matching mechanism 5, and the plank is planed by the cutting mechanism 4. Each pair of cutting mechanism 4 After planing a groove on the washboard, the cooperation mechanism 5 drives the washboard to move a certain distance, and the cutting mechanism 4 continues...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 with Image 6 As shown, it also includes a third support plate 6, a placement box 7 and a handle 8. The rear side of the upper part of the bottom plate 1 is provided with a third support plate 6, and the left and right sides of the third support plate 6 are respectively connected with the first support plate 2 and the second support plate. The support plate 3 rear parts are connected, and the third support plate 6 bottom is slidingly equipped with a placement box 7, and a handle 8 is provided in the middle of the lower side of the rear portion of the placement box 7.

[0031] Cutting mechanism 4 will drop a little sawdust while planing the washboard, and a placement box 7 is arranged below the washboard, so that the fallen sawdust can fall in the placement box 7. When the sawdust in the placement box 7 reaches When a certain amount, pull back the moving handle 8, and then make the placement box 7 move to the left, take out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com