Efficient rotational flow multistage purification device for mine wastewater treatment

A technology for mine wastewater, grade purification, applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of single technology, inconvenient operation, waste of land resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

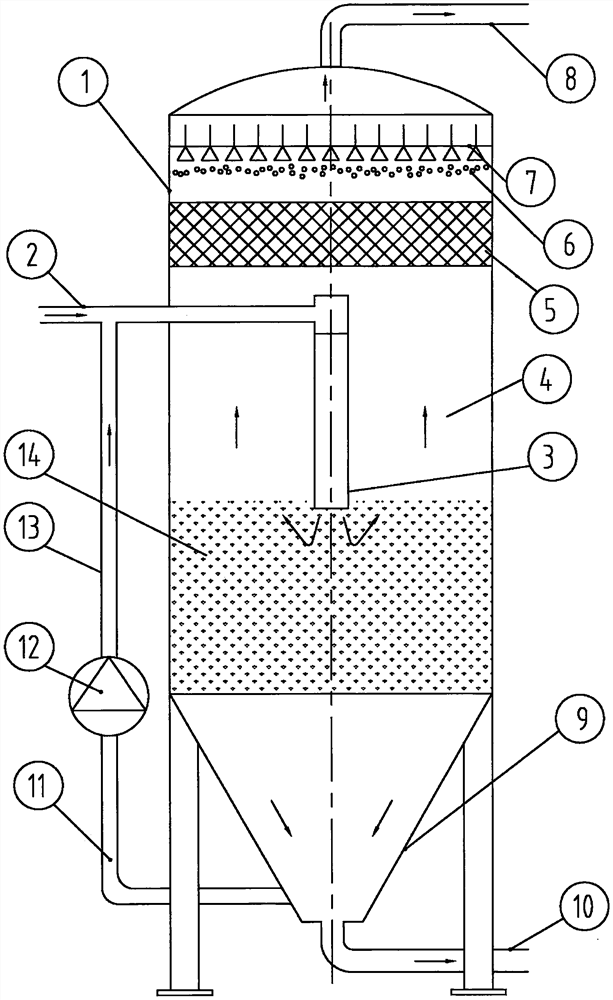

[0013] The following is attached figure 1 The principles and features of the present invention are described, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0014] In this embodiment of the present invention, the cylindrical body 1 is cylindrical, and the water inlet pipe / backwash drain pipe 2 passes through the upper side of the cylindrical body 1 and is connected to the swirl central cylinder 3, The swirl center tube 3 is installed in the inner cavity 4; when the equipment is fed with water, water flows through the water inlet pipe / backwash drain pipe 2 and enters the swirl center tube 3 along a tangent line; the special-shaped inclined plate 5 is fixedly connected to the side wall of the cylindrical body 1, and has a conical shape, a polygonal shape, etc., and belongs to a multi-layer structure; the filter material 6 and the filter plate 7 together form a filter material layer, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com