Crown structure of large-scale oxygen-fuel combustion glass kiln

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

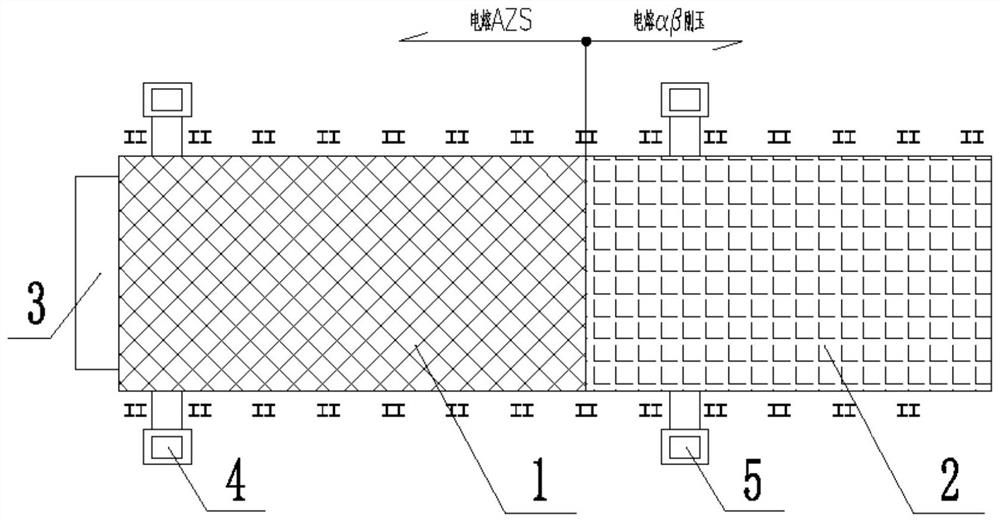

[0036] like figure 1 As shown, the large wall is divided into two parts: the front wall 1 and the rear wall 2. The front wall 1 of the kiln uses AZS zirconium corundum bricks, and the rear wall 2 uses αβ corundum bricks. Between the two pairs of vertical flues is a high-temperature melting zone, and behind the vertical flues is a clarification zone with a lower temperature. AZS zirconium corundum material is used in the high temperature area at the front, which can reduce the cost. The molten vertical flow produced by Dalong drips into the melting pool and can be melted at high temperature without affecting the quality. The use area is from the feeding port 3 to the rear. There is a set of distance between the second group of large rails before the vertical flue 5 and the rear vertical flue 5, so that the molten vertical flow produced by the AZS large rails has a certain high-temperature melting time after it drops into the melting pool. Choose to use pure αβ corundum bricks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com