A thermal insulation board production line

A production line, insulation board technology, applied in textile and papermaking, spray/jet textile material processing, static electricity and other directions, can solve the problems of long curing time, difficult pressure, small thickness of insulation board, etc., to improve automation ability, improve Material uniformity, the effect of reducing fiber static

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

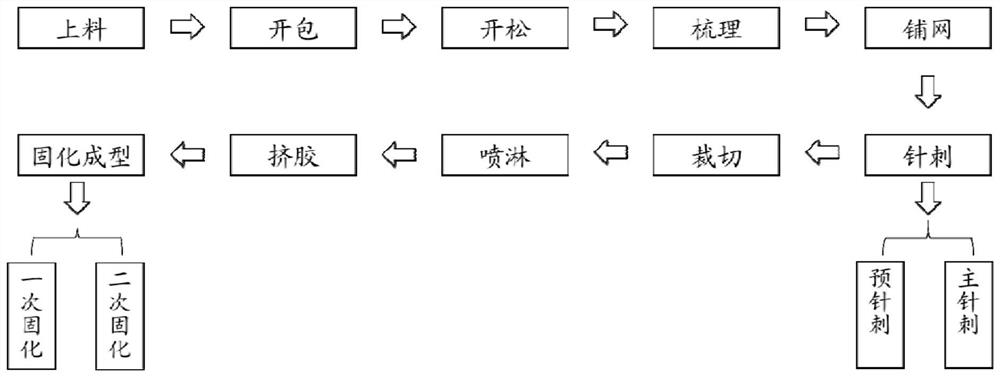

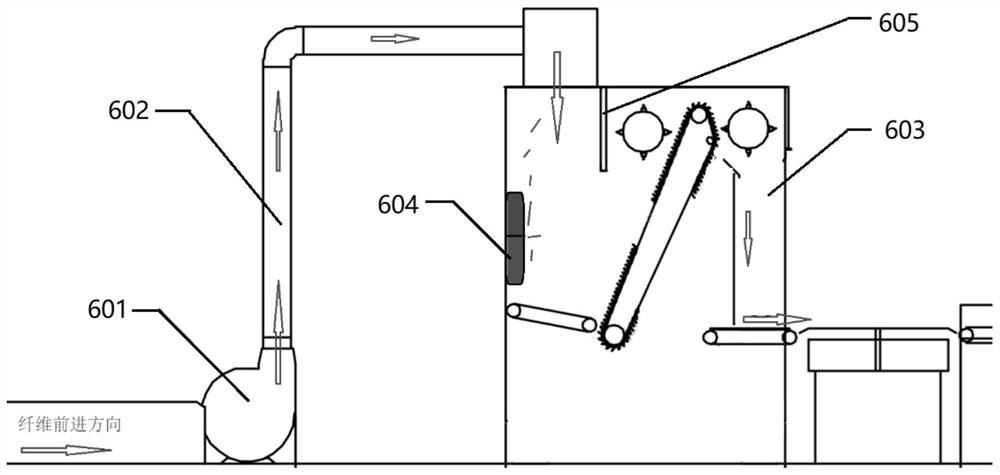

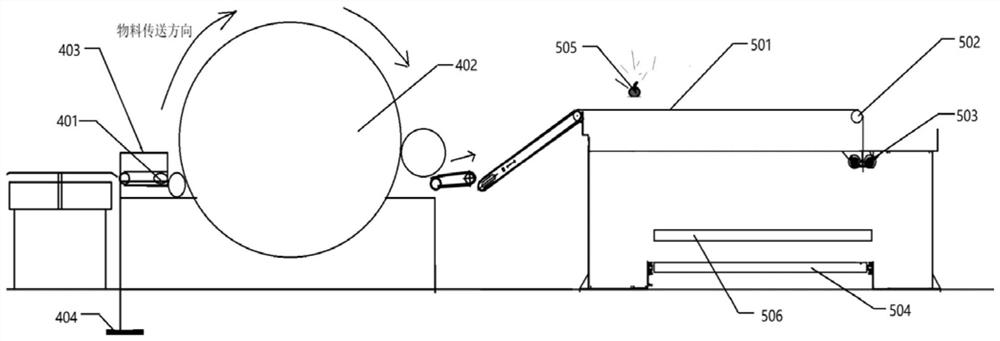

[0092] A production line for the insulation board for building exterior walls, including upper, open bags, open, sorted, spread, acupuncture, cut, spray, extrusion, and curing forming steps. The feedstock of the insulation plate is: glass fiber and water-soluble phenolic resin, where glass fibers are prepared: 4860 kg of alkali glass fibers, 14580 kg of middle alkali glass fibers and 10 μm, and length 75 mm. Water-soluble phenolic resin was prepared from 3240 kg, 25 ° C having a viscosity of 13 cp, a solid content of 49 wt%, pH 10.0.

[0093] Glass fibers have been automatically charged (122kg per hour, 122kg), 365 kg of alkali glass fibers), open clamping machine, open machine, sorting machine, net mesh, needle, conveyor to the shower machine ( Spray water soluble resin amount 99 kg / h), a microwave cured device for a cure, a microwave curing apparatus for secondary cure, 1 hour after 1 hour, a new fire thermal insulation plate of a width of 2m, thickness of 28 mm, length 30m, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com